You’re standing in the middle of the hardware aisle, staring at a wall of circular saw blades, and honestly, it’s a mess. Most people think a circular saw—often called a "skill saw" regardless of the brand—is just for 2x4s and plywood. But the second you need to slice through a piece of angle iron or some copper pipe, the panic sets in. Can you actually put a metal cutting blade for skill saw use on that tool?

The short answer is yes. The long answer is that if you do it wrong, you’re looking at a shower of molten sparks, a ruined motor, or a blade that shatters faster than your patience.

It's about physics. Wood blades tear through fibers using high speeds and aggressive "gullets" (those big gaps between teeth). Metal is different. Metal requires friction management and heat dissipation. If you try to use a standard wood blade on steel, you aren’t cutting; you’re just making a very expensive, very loud mistake.

The Myth of the "One Size Fits All" Metal Blade

There’s this weird idea floating around DIY forums that any blade labeled "multi-material" is the gold standard. It isn't.

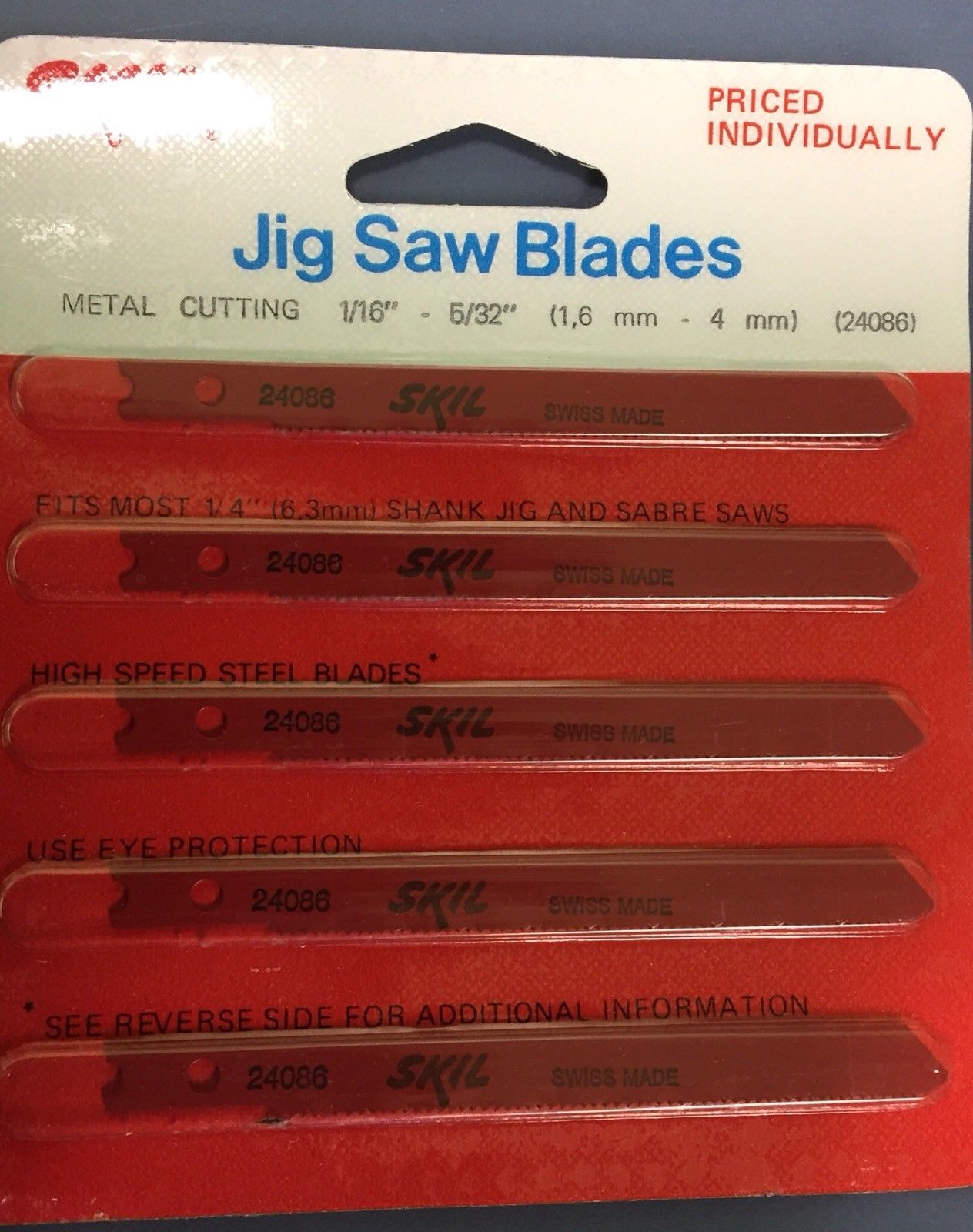

When you’re looking for a metal cutting blade for skill saw setups, you have to decide between two completely different technologies: abrasive discs and Cermet-tipped (Ceramic-Metallic) or Carbide-tipped blades.

Abrasive discs are those gritty, sandpaper-looking things. They’re cheap. They also suck. They shrink as you use them, they smell like a burning tire factory, and they throw enough sparks to set your garage on fire. More importantly, they "grind" rather than "cut." This creates massive amounts of heat, which can actually change the temper of the metal you’re working with, making it brittle or warped.

🔗 Read more: Images of iPhones: What Most People Get Wrong About Photography and Design

Why Cermet and Carbide Changed Everything

If you want a clean, cool-to-the-touch cut, you go with a TCT (Tungsten Carbide Tipped) blade. These are the heavy hitters. Companies like Diablo (specifically their Steel Demon line) and Lenox have basically perfected this. Instead of grinding away at the steel, these blades have teeth specifically ground to a "Triple Chip Grind" (TCG).

This geometry allows the blade to shear the metal. Because it’s shearing rather than grinding, the heat stays in the chips, not the workpiece. You can literally pick up a piece of steel right after cutting it with a Steel Demon blade and it won't burn your hand. Try doing that with an abrasive disc and you’ll be heading to the ER.

RPM: The Silent Killer of Saw Motors

Here is the thing nobody tells you at the big-box stores. A standard 7-1/4 inch skill saw spins at about 5,800 RPM. That is screaming fast. Most dedicated metal-cutting saws (like those heavy-duty cold saws used in fabrication shops) spin at a much lower speed, usually around 1,500 to 3,900 RPM.

When you slap a metal cutting blade for skill saw onto a high-speed wood saw, you are pushing the blade beyond its design limits.

The tips of the teeth are moving so fast that they can’t properly "bite" into the metal. Instead, they bounce. This chatter ruins the blade's life and puts an insane amount of strain on your saw’s motor. If you’re going to do this, you need a blade specifically rated for those high RPMs. Don't just grab a blade meant for a low-speed dry-cut saw and hope for the best. Check the packaging. If the max RPM on the blade is lower than the RPM listed on your saw's nameplate, put it back. Seriously.

Cutting Different Metals: It’s Not Just "Steel"

You’ve got to match the blade to the "flavor" of the metal.

- Aluminum: This stuff is sticky. It’s a non-ferrous metal that loves to clog up saw teeth. You need a blade with a high tooth count and you absolutely should use a lubricant like a wax stick or even WD-40. If the aluminum "galls" (welds itself to the teeth), the blade is basically toast.

- Stainless Steel: This is the boss fight of metal cutting. Most standard carbide blades will dull instantly against stainless. You need something specifically labeled for "Stainless," usually featuring a Cermet II grade carbide.

- Thin vs. Thick: If you’re cutting sheet metal, you want more teeth. If you’re cutting 1/4 inch plate, you want fewer, beefier teeth. Using a high-tooth blade on thick plate creates too much friction. It’ll glow red and die.

Real-World Safety (The Stuff the Manual Skips)

I’ve seen guys use a metal cutting blade for skill saw while wearing a synthetic "dry-fit" shirt. Don't be that guy. Those tiny hot chips will melt right through polyester and fuse to your skin. Wear 100% cotton or leather.

Also, your saw’s plastic guard? It’s not built for metal. Metal chips are abrasive and hot. Over time, they can pit the plastic or even melt the inner housing of a cheap saw. If you’re doing a lot of metal work, it’s worth buying a dedicated metal-cutting circular saw from a brand like Milwaukee or Evolution. Those saws have closed guards to catch the chips and motors geared for higher torque at lower speeds.

But if you’re just doing the occasional project, your regular saw will survive—if you’re careful.

📖 Related: YouTube Private Video Viewer: Why Most "Shortcuts" Are Actually Scams

The Secret Technique: Don't Push It

When cutting wood, we tend to "feed" the saw pretty hard. With metal, you have to let the blade do the work. If you hear the motor bogging down, you're pushing too hard.

Listen to the sound.

A good metal cut sounds like a consistent, high-pitched "zip." A bad cut sounds like a grinding, screaming protest. If the saw starts vibrating excessively, stop. Check for missing teeth. One missing carbide tip creates an imbalanced centrifugal force that can lead to a catastrophic blade failure. It's not worth the $50 blade to risk a piece of carbide flying into your leg at 100 miles per hour.

The Longevity Trade-off

Let’s talk money. A good carbide metal cutting blade for skill saw will cost you anywhere from $40 to $70. An abrasive disc costs $5.

It feels like the abrasive disc is the better deal, right? Wrong. One carbide blade will outlast 30 to 50 abrasive discs. Plus, you save time because you aren't stopping to change a shrinking disc every three cuts. You get straighter lines, cleaner edges, and less cleanup. It’s a classic case of "buying cheap is expensive."

Actionable Steps for Your Next Project

If you’re ready to start cutting metal with your circular saw, don’t just wing it. Follow this checklist to make sure you don't destroy your equipment:

1. Verify your saw's RPM. Look at the sticker on the motor. If it’s a standard 5,000+ RPM saw, you MUST buy a blade rated for that speed. Look for "7-1/4 inch Steel Cutting" specifically designed for circular saws, not miter saws.

2. Clear the area. Metal chips are basically tiny knives. They will get into everything. If you have a finished car in the garage, move it. If you have piles of sawdust nearby, get rid of them. Hot metal chips + sawdust = fire. It happens faster than you think.

🔗 Read more: How to Do Crossfade on Apple Music Without Breaking Your Playlists

3. Secure the workpiece. Never "freehand" metal. It will kick back. Use heavy-duty C-clamps or a dedicated welding table. If the metal moves while the blade is in the cut, the carbide teeth will shear off instantly.

4. Protect your eyes and ears. Cutting metal with a skill saw is incredibly loud—sometimes hitting 110 decibels. Use foam plugs AND over-ear muffs. For eyes, use a full face shield over your safety glasses. A chip hitting your cheek at high speed is no joke.

5. Check for "Heat Blues." After your cut, look at the edge. If the metal is blue or deep purple, you’re generating too much heat. Slow down your feed rate or check if the blade is dull. A clean cut should leave the metal looking shiny and silver.

Metal cutting doesn't have to be a scary, spark-filled nightmare. With the right blade and a little bit of respect for the physics involved, you can turn your standard woodworking saw into a serious fabrication tool. Just remember: the blade is the boss. If you treat it right, it’ll slice through angle iron like it’s butter. If you disrespect the RPM limits or the material type, it’ll be a very short, very expensive afternoon.