You've seen them. Those generic resumes that just say "handy with tools" or "good at fixing things." Honestly, it’s a waste of space. If you are applying for a role that requires actual technical grit, the phrase maintenance skills for resume shouldn't just be a header; it needs to be a roadmap of everything you’ve actually touched, broken, and fixed. Managers are tired of reading the same five bullet points. They want to know if you can handle a $50,000 piece of equipment without calling a contractor every time a light flickers.

The reality of the job market in 2026 is that "general maintenance" isn't a skill anymore. It’s a category. You have to be specific. Are you a PLC wizard? Can you weld underwater? Or are you the person who knows exactly why the HVAC system in a 40-story building is humming at the wrong frequency? If you can't articulate that on paper, you're invisible.

The Skill Gap Most People Ignore

Most applicants think maintenance is just about turning a wrench. It’s not. It’s about data. Today, if you don't have some level of digital literacy, you’re basically a dinosaur in a hard hat. Modern facilities use Computerized Maintenance Management Systems (CMMS) like Upkeep or Fiix. If you’ve used these, put them front and center. It shows you understand the workflow of a modern shop, not just how to patch a wall.

I talked to a hiring manager at a major logistics hub last month. He told me he throws out any resume that doesn't mention "preventative maintenance." Why? Because any amateur can fix something once it’s already broken. A pro knows how to stop it from breaking in the first place. That’s the difference between a $20-an-hour job and a $45-an-hour career. You need to prove you have the foresight to manage a schedule, not just a toolbox.

The Technical Heavy Hitters

Let’s get into the weeds. If you’re building your list of maintenance skills for resume, you need to categorize them so a recruiter’s eyes don't glaze over.

Electrical is king. If you can read a schematic and understand 480V three-phase power, you are ahead of 80% of the pack. Don't just say "electrical." Say "troubleshooting industrial control panels" or "replacing VFDs (Variable Frequency Drives)."

Hydraulics and Pneumatics. In manufacturing, everything moves via air or fluid. If you can rebuild a cylinder or hunt down a leak in a high-pressure line, that is gold.

Plumbing. But not just "fixing a sink." Think backflow prevention, pipe fitting, or copper sweating.

Carpentry and Masonry. This is more for facility roles. Drywall is fine, but can you frame a wall or pour a pad for a new compressor?

👉 See also: Getting a music business degree online: What most people get wrong about the industry

It's also about the tools. Don't list "wrenches." List "multimeters," "oscilloscopes," "laser alignment tools," or "thermal imaging cameras." Using a FLIR camera to find a hot spot in a breaker is a high-level skill. Mentioning it proves you know what "predictive maintenance" actually means.

Why Soft Skills are Actually Hard Skills

People laugh when I say a maintenance tech needs "communication skills." They think it means being nice. Nope. In this field, communication means being able to explain to a plant manager why the production line is down and exactly how many hours it will take to get it back up. It means writing a clear shift handover report so the next guy doesn't get electrocuted.

"Problem-solving" is another one that everyone puts on their resume, but nobody explains. Instead of just listing it, give an example. "Diagnosed a recurring bearing failure that saved the company $12,000 in annual replacement costs." That is a maintenance skill. It shows you have an analytical mind. You aren't just swapping parts; you're finding the root cause.

Budgeting matters too. If you’ve ever had to order parts or manage a shop inventory, you’re doing "vendor management" and "inventory control." These are massive for senior or lead roles. It proves you understand the business side of the boiler room.

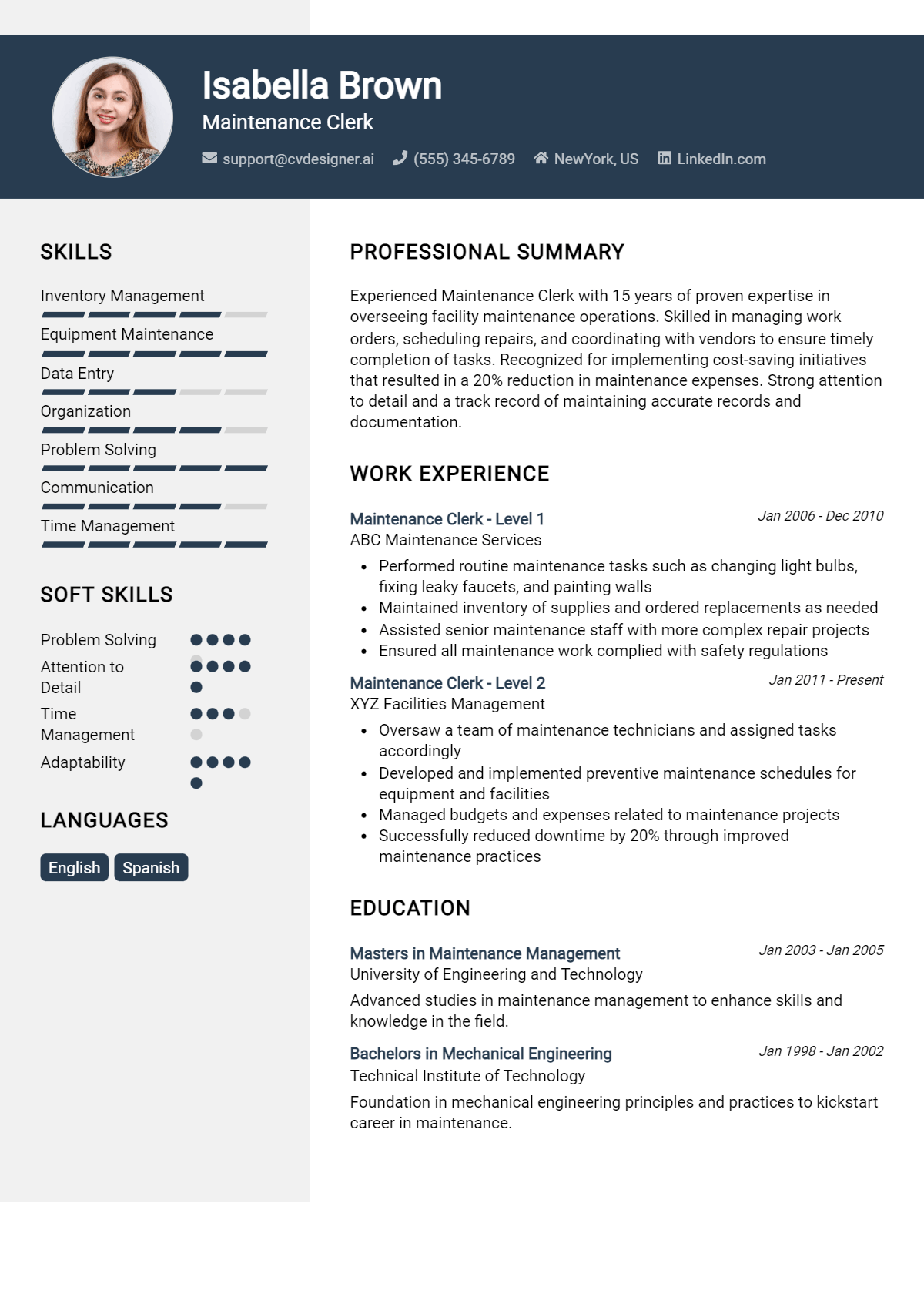

How to Format Without Looking Like a Bot

Recruiters spend about six seconds looking at your resume. If it looks like a wall of text, they’re out. If it looks like a perfect, AI-generated table, they might think you’re faking it. You want a mix.

Use a "Core Competencies" section. Keep it punchy.

- PLC Programming (Allen-Bradley/Siemens)

- Predictive Maintenance & Vibration Analysis

- Blueprint & Schematic Reading

- OSHA 30-Hour Certified

- Industrial HVAC (EPA 608 Universal)

Then, in your job history, don't just list your duties. List your wins. "Maintained 98% uptime for a fleet of 50 forklifts" sounds way better than "Fixed forklifts." Use numbers. Percentages. Dollar signs. The language of business is money, and maintenance is the art of saving it.

The Hidden Value of Certifications

Certifications are the "proof of work" for maintenance skills for resume. You can say you’re a great electrician, but a Journeyman license says it for you.

✨ Don't miss: We Are Legal Revolution: Why the Status Quo is Finally Breaking

- CMRP (Certified Maintenance & Reliability Professional): This is the gold standard for people who want to move into management. It’s hard to get, and it commands a high salary.

- EPA Section 608: If you touch AC units, you need this. It’s non-negotiable.

- PMP (Project Management Professional): Rare in maintenance, but if you do large-scale facility upgrades, this makes you a unicorn.

- CUST (Certified Underground Storage Tank) Operator: Very niche, very high demand in certain sectors.

If you have these, they should be at the very top. Not buried at the bottom under "Hobbies."

Different Strokes for Different Industries

A maintenance tech at a hospital has a totally different day than one at a Tesla factory. You have to pivot. For healthcare, emphasize sterilization equipment, emergency generators (life safety systems), and HVAC (air pressure zones). For manufacturing, it’s all about robotics, conveyors, and fast-paced repair.

If you’re applying for property maintenance, focus on "make-readies," appliance repair, and customer service. People in apartments are stressed when their heat goes out. Showing you can handle a frustrated tenant while fixing a furnace is a specific skill set.

Avoid the "Jack of All Trades" Trap

Being a generalist is okay for entry-level, but the money is in the niche. If you try to list 50 different skills, it looks like you’re "kinda" good at everything and "actually" good at nothing. Pick your three strongest "pillars." Maybe it’s Welding, Electrical, and Hydraulics. Build the rest of the resume around those.

Honestly, the biggest mistake is being too humble. Maintenance folks are usually the "get it done" types who don't like to brag. But your resume is the one place where you have to be loud. If you saved a building from flooding during a pipe burst at 3 AM, write it down. That shows reliability and "emergency response"—two things you can't teach in a classroom.

The Evolution of Maintenance in 2026

We are seeing a massive shift toward IoT (Internet of Things) and sensors. Equipment now tells you when it’s going to fail. If you’ve worked with sensors that feed data into a dashboard, you need to mention "Remote Monitoring" and "IoT Integration." This is the future of the trade. Companies are moving away from "fix it when it breaks" to "fix it because the sensor tripped a warning." If you can navigate that software, you are incredibly valuable.

Also, don't forget safety. LOTO (Lockout/Tagout) is the bread and butter of shop safety. If you don't mention your commitment to safety protocols, you’re a liability. No manager wants a "cowboy" who takes risks to save ten minutes. They want someone who follows the manual and goes home with all their fingers.

Specific Examples for Your Experience Section

Instead of: "Responsible for machine repair."

Try: "Executed 150+ monthly work orders for CNC machinery, reducing unplanned downtime by 20% over 12 months."

🔗 Read more: Oil Market News Today: Why Prices Are Crashing Despite Middle East Chaos

Instead of: "Handled plumbing issues."

Try: "Managed full-scale replacement of commercial boiler systems and associated piping, ensuring compliance with local building codes."

Instead of: "Worked with tools."

Try: "Proficient in precision measurement tools including micrometers and calipers for tolerances within .001 inch."

See the difference? One is a list of chores. The other is a list of professional capabilities.

Actionable Next Steps

To actually get your resume noticed, stop sending the same PDF to every job posting.

- Audit your current list. Look at your skills. If you see "Hardworking" or "Team Player," delete them. Those aren't maintenance skills; those are basic requirements for being an adult. Replace them with "Arc Welding" or "Steam Trap Testing."

- Scan the job description. If the job mentions "conveyors" three times, and you’ve worked on conveyors, that word better be in your resume four times.

- Get a new cert. If you feel your resume is light, spend a weekend getting a specialized certification. It shows you’re still learning.

- Quantify everything. Go through your last job and find three times you saved money or time. Put those in bold.

- Check your tech. Make sure you’ve listed every software you’ve used, from Excel (for tracking parts) to complex CMMS platforms.

The goal isn't just to show you can work. It’s to show you can manage the complexity of modern infrastructure. That is how you win.

Next Phase: Resume Optimization

Focus on the "Professional Summary" at the top. Instead of saying "Maintenance worker looking for a job," try "Certified Maintenance Technician with 10+ years in industrial environments specializing in PLC troubleshooting and preventative maintenance programs." It sets the tone immediately. Check your local community college for specialized short-courses in "Green Building" or "Industrial Automation" to stay ahead of the 2026 curve. High-efficiency systems are the new standard, and knowing how to maintain them is your ticket to the next pay grade.

---