You’re standing in your laundry room, staring at a tub full of soapy, lukewarm water that refuses to move. It’s frustrating. Maybe the drum gave a pathetic little twitch before giving up, or perhaps you’re staring at an LE error code that won't go away. This is usually the moment people start Googling the price of a new washing machine. But honestly, the problem is often just a $20 plastic part hidden behind the motor. The LG washer hall sensor is a tiny component that handles a massive job, and when it fails, your high-tech appliance becomes an expensive paperweight.

It’s basically the brain’s eyes.

In a direct drive system, which LG pioneered and made famous, the motor sits right on the back of the drum. There are no belts. No pulleys. Just magnets and coils. Because the motor is so powerful, the control board needs to know exactly how fast that drum is spinning and where it is in its rotation. That is where the hall sensor comes in. It uses the Hall Effect—a magnetic phenomenon discovered by Edwin Hall in 1879—to track the position of the motor's rotor. If the sensor can't "see" the magnets passing by, the computer gets scared. It assumes the motor is locked or the load is dangerously unbalanced, so it kills the power.

Safety first, right? But it's annoying when you just want clean socks.

The LE Error Code and Other Red Flags

Most people first encounter the LG washer hall sensor when the "LE" code pops up on the digital display. LE stands for Load Error, but that’s a bit of a misnomer. It’s actually a communication breakdown.

You might hear a rhythmic clicking sound. Or the drum might agitate for two seconds and then stop. Sometimes, the machine works fine for a small load of delicates but dies the second you throw in a couple of heavy bath towels. This happens because a weak sensor might still pick up magnetic signals at low torque, but as soon as the motor has to work harder, the electrical "noise" or physical vibration causes the sensor to lose its place.

Don't just assume it's the sensor, though. Expert technicians like the ones at Appliance Repair School or veteran DIYers on forums like Houzz often point out that a wire harness can rub against the vibrating tub. Over five or six years, that friction wears through the insulation. You might replace the sensor only to find the problem persists because a single thin wire is grounding out against the metal frame. Check your wiring first. It’s free.

Why do these things actually break?

Heat is the primary enemy here. Washing machines live in a cycle of getting hot and vibrating violently. The hall sensor is a small circuit board encased in a plastic housing. Over time, the solder joints on that tiny board can develop "cold cracks." These are microscopic fractures that expand when the motor gets warm.

- Moisture is another culprit.

- Corrosion on the pins.

- Excessive sudsing (oversudsing) can actually cause enough resistance to stress the motor's feedback loop.

- Physical trauma from a catastrophically unbalanced load hitting the rear cover.

Deep Diving into the Direct Drive Mechanics

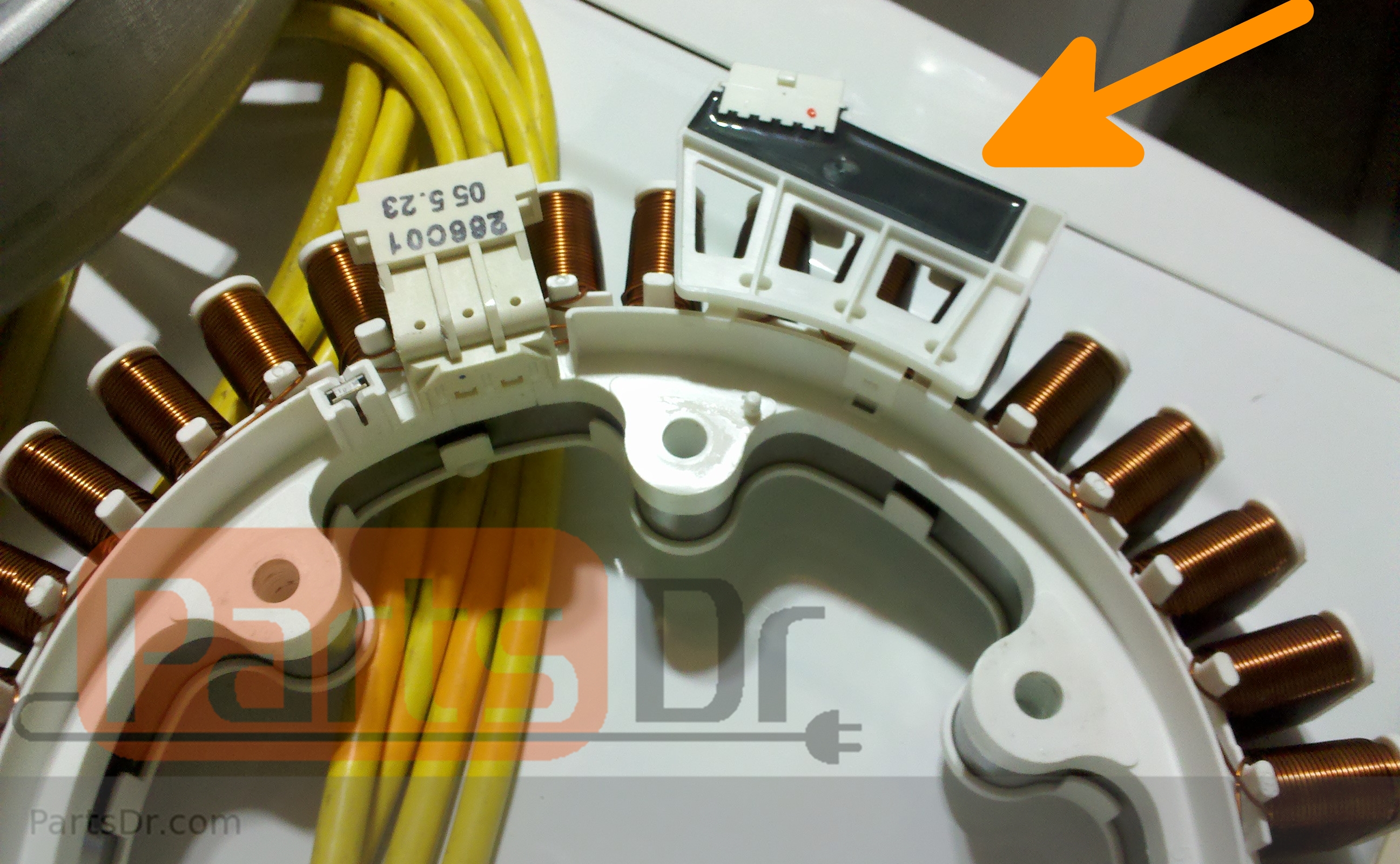

To understand why the LG washer hall sensor is so critical, you have to look at the stator. The stator is that big ring of copper-wound poles bolted to the back of your washer. The rotor—the big metal bowl with magnets inside—fits over it.

When you start a cycle, the main control board sends three-phase power to those copper coils. This creates a rotating magnetic field. The rotor wants to follow that field. The hall sensor sits right on the edge of the stator, hovering just millimeters away from the rotor's magnets. As the magnets fly past, the sensor toggles on and off.

It sends a pulse. Click-click-click.

The computer counts these pulses. If the computer expects 50 pulses per second but only gets 40, it knows the motor is slipping or bogged down. If it gets zero pulses but knows it’s sending power to the motor, it triggers the LE code instantly to prevent the motor from burning itself out. It’s a brilliant system until a five-cent resistor on that sensor board decides to quit.

How to Test the Sensor Without Buying New Tools

You don't necessarily need a fancy oscilloscope to see if your LG washer hall sensor is toast. You do need a multimeter, though. If you don't have one, they're cheaper than a pizza these days.

First, unplug the machine. Safety isn't optional here. You have to take the back panel off and remove the large center bolt holding the rotor on. Be careful—those magnets are strong and they love to pinch fingers. Once you have the rotor off, you’ll see the stator. The hall sensor is a small, usually white or gray, rectangular clip attached to the bottom or side of the stator.

Unplug the wire harness from the sensor. Set your multimeter to the "Diode" setting or a high resistance (Ohms) setting. You're looking for consistency. There are usually five pins on these sensors. You want to test the resistance between the ground pin (usually center) and the two signal pins. If you get an "Open" reading (OL) or a wildly different number on one side compared to the other, the sensor is dead.

Honestly, though? Most pros don't even bother testing them anymore. Because the part is so cheap—often under $30—and the labor to get to it is the same whether you're testing or replacing, most people just swap it out. It’s a "while you're in there" type of repair.

The "Reset" Trick That Sometimes Works

Before you go tearing your laundry room apart, there is a "soft reset" that works more often than it should. It’s basically the "have you tried turning it off and back on again" of the appliance world.

- Unplug the washer from the wall.

- Press and hold the Start/Pause button for 5 full seconds.

- Press and hold the Power button for 5 full seconds.

- Plug the machine back in.

This drains the capacitors on the main control board. Sometimes, the LE code is just a "ghost" error caused by a momentary power surge or a weird glitch in the software. If the machine starts working after this, you might have just saved yourself a Saturday afternoon of mechanical labor. If the code comes back during the first spin cycle, your LG washer hall sensor is definitely calling it quits.

Replacing the Sensor: A Realistic Walkthrough

If you've decided to DIY this, it’s a medium-difficulty job. You need a 10mm socket for the back panel and a 17mm (usually) large socket for the rotor bolt.

One thing people mess up? The rotor bolt is on there tight. You might need a piece of wood to jam the rotor so it doesn't spin while you're cranking on the wrench. Once that bolt is out, pull the rotor straight back. It will resist you because of the magnets. Just give it a firm, steady tug.

The stator is held on by six bolts. You don't always have to take the stator off to get to the sensor, but it makes it a lot easier. If you do take it off, be gentle with the copper windings. If you scratch the insulation on those wires, you’re looking at a $150 stator replacement instead of a $20 sensor fix.

The sensor just clips on. Use a flathead screwdriver to pop the tabs, slide the old one out, and click the new one in. It’s satisfying. Reassemble in reverse order. Make sure that big center bolt is incredibly tight when you put the rotor back on. If it’s loose, it will wobble, and a wobbly rotor will eat a brand-new LG washer hall sensor for breakfast in about three wash cycles.

Misconceptions About the Hall Sensor

A lot of people think the hall sensor controls the water level or the temperature. It doesn't. If your washer isn't draining, that's the drain pump. If it's not getting hot, that's the heating element or thermistor.

Another big myth is that a bad hall sensor will always cause an LE code. Not true. Sometimes a failing sensor causes the drum to shake violently during the start of a cycle because the motor is "hunting" for its position. It looks like an unbalanced load, but even with an empty drum, it thumps and bumps. This is because the timing is off.

It’s like a car engine with a bad spark plug. It runs, but it’s miserable.

Is it worth fixing?

If your washer is less than 10 years old, absolutely. LG's direct drive motors are actually very robust. The bearings usually go out before the motor does. Spending $25 on a LG washer hall sensor and an hour of your time is much better than spending $900 on a new front-loader that probably has the same sensor design anyway.

👉 See also: Qi Wireless Charging Pad: Why Yours Probably Feels So Slow

Taking Action: Your Next Steps

Stop using the machine immediately if you're getting an LE code. Forcing it to run by repeatedly restarting it can overheat the stator coils.

Order the part using your specific model number found on the inside of the door frame. Don't just buy a "universal" LG sensor; there are two or three different versions depending on whether you have a top-loader or a front-loader.

Check the wiring harness for "chafing." Look for any white powder or frayed copper near the motor. If the wires are damaged, wrap them in high-quality electrical tape or splice in new wire if you're comfortable with a soldering iron.

Once the new sensor is in, run a "Tub Clean" cycle. This calibrates the new sensor and ensures the drum is balanced without the stress of a heavy laundry load. If it passes the Tub Clean, you're back in business. You just saved yourself a massive repair bill by understanding a little bit of magnetism and having the guts to take a wrench to your appliance.