You've probably seen the boxes. If you spend any time at a shooting range or browsing the aisles of a sporting goods store, that small "LC" headstamp on the brass is unmistakable. It’s the calling card of the lake city ammunition plant independence missouri. But here is the thing: most people think of it as just another factory. It isn't. It’s more like a small, high-security city that basically dictates the rhythm of the American small arms world.

Located on nearly 4,000 acres in Independence, Missouri, this place is massive.

Honestly, the scale is hard to wrap your head around until you’re standing near the perimeter fence. We are talking about a government-owned, contractor-operated (GOCO) facility that has been the backbone of U.S. military small arms production since the early 1940s. It’s currently managed by Olin Corporation (specifically the Winchester division), but it has swapped hands between big names like Remington and Northrop Grumman over the decades.

Why the Lake City Ammunition Plant Independence Missouri actually exists

Let's go back to 1941. The world was on fire. The U.S. realized it didn't have nearly enough capacity to feed the rifles of a multi-front global war. So, Remington Arms set up Lake City. Since then, it’s been the primary source for 5.56mm, 7.62mm, and .50 caliber rounds for the Department of Defense.

It’s not just a business. It’s a strategic asset.

If Lake City stops, the military’s training and readiness basically grind to a halt within months. That’s why the "government-owned" part is so crucial. The feds own the land and the machines; they just hire experts to run the day-to-day. This creates a weird, often misunderstood relationship with the civilian market. People get riled up every time there is a rumor that the lake city ammunition plant independence missouri is going to stop selling "surplus" or "excess" ammo to civilians.

The myth of the "Civilian Ban"

You’ve likely heard the rumors. Every couple of years, a panic sweeps the internet: "The White House is banning Lake City 5.56 sales!"

Usually, it’s a misunderstanding of how the contract works.

The plant’s first priority is always the U.S. Army. Always. If there’s a massive surge in military demand—think the early years of the Iraq War—the plant has less capacity to churn out extra for the commercial market. It isn’t necessarily a "ban" by decree; it’s just the reality of production schedules. When the military doesn't need the full capacity of the 1.4 billion rounds the plant can produce annually, that excess is sold to us, the public, often under the Winchester or Federal labels.

Inside the monster: How the ammo is actually made

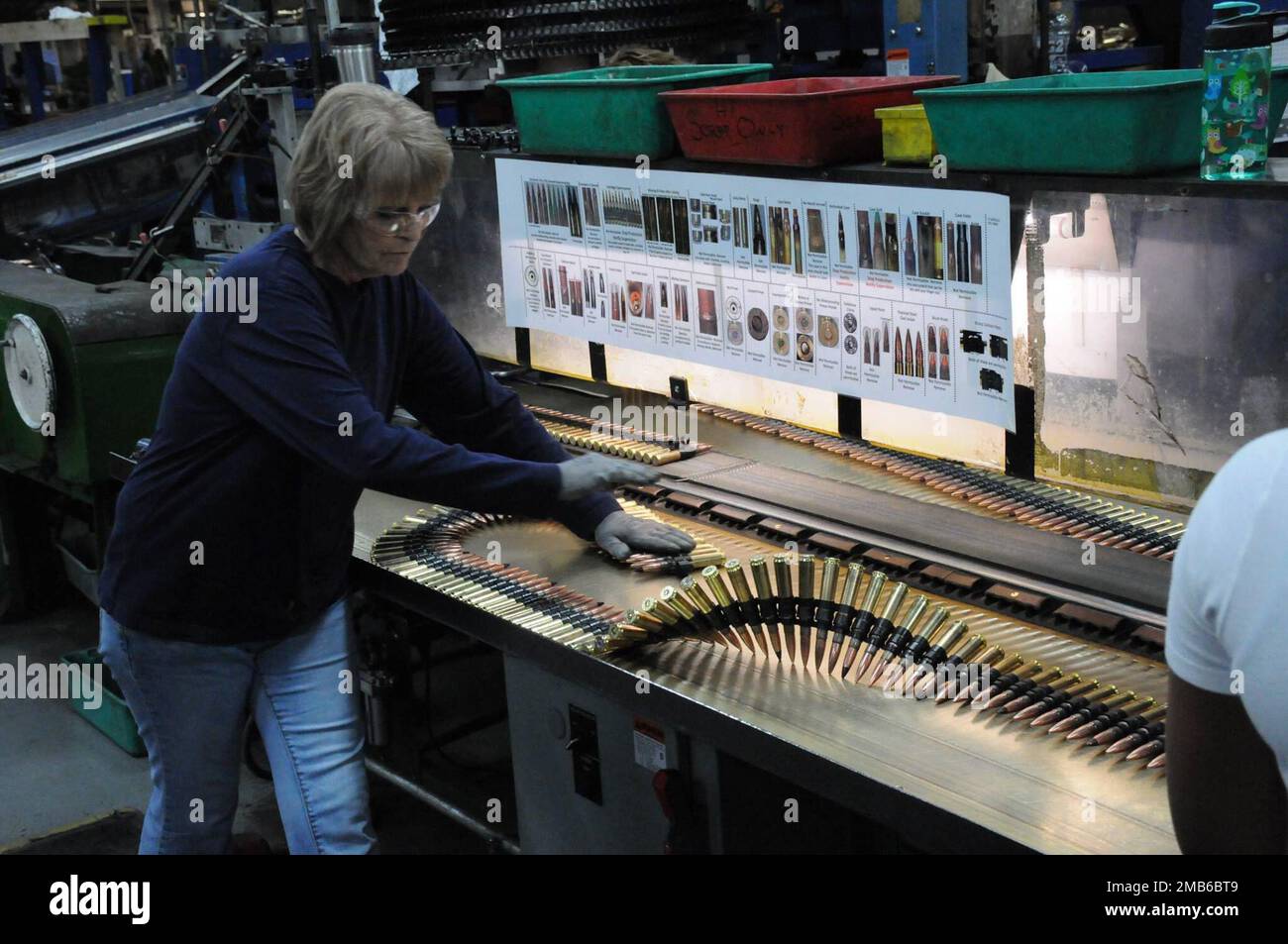

This isn't a clean-room tech startup. It’s heavy industry. It’s loud. It’s hot.

✨ Don't miss: Starting Pay for Target: What Most People Get Wrong

The process starts with raw materials: massive coils of brass and lead. The 5.56mm NATO round, which is the plant's bread and butter, goes through a series of "draws." Imagine taking a small cup of brass and stretching it thinner and longer until it looks like a casing. Then comes the annealing—a heat treatment that makes the brass durable enough to be reloaded.

One thing that surprises people is the testing.

Lake City doesn't just "hope" the ammo works. They have onsite ballistic labs and ranges where they test for pressure, velocity, and accuracy. They aren't just checking one out of every thousand rounds, either. The quality control protocols are some of the most stringent in the world because if a round fails in a soldier’s rifle, the stakes are literally life and death.

The 6.8mm NGSW shift

Things are changing. The Army is moving toward the Next Generation Squad Weapon (NGSW) program. This means transitioning from the 5.56mm to a new 6.8mm round. This is a huge deal for the lake city ammunition plant independence missouri.

They’ve had to build entirely new production lines.

The 6.8mm isn't just a bigger bullet; it’s a higher-pressure system that often uses composite or high-pressure brass casings. It’s arguably the biggest change to the plant’s workflow since the Vietnam War. Watching a legacy facility like Lake City pivot to this new tech is like watching an aircraft carrier make a U-turn. It’s slow, expensive, but once it’s heading in that direction, it’s unstoppable.

Environmental and safety headaches

You can’t run a massive chemical and metallurgical plant for 80 years without making a mess. It’s just the truth.

The Independence community has a complicated relationship with the site. Over the years, there have been concerns about groundwater contamination and lead exposure. To their credit, the Army and the various contractors have spent hundreds of millions on remediation. But the scars of mid-century industrialism are deep.

There’s also the explosive risk.

🔗 Read more: Why the Old Spice Deodorant Advert Still Wins Over a Decade Later

In 2017, there was a tragic explosion in one of the primer mixing buildings. It killed one worker and injured others. When you are dealing with tons of primary explosives—the stuff that makes the "bang"—there is zero margin for error. The plant has its own fire department and emergency response teams because you can't just call the local city fire station and ask them to handle a specialized ordnance fire.

The economic footprint in Independence

Let's talk jobs. Around 1,800 to 2,000 people work at Lake City. In a town like Independence, that’s a massive economic engine. These are often multi-generational jobs. You’ll find grandfathers who retired from Lake City whose grandsons are now running the CNC machines or the packing lines.

It’s a blue-collar stronghold.

The pay is generally good, and the benefits are solid because of the high-stakes nature of the work. But the plant is also a bellwether for the global political climate. If there’s peace, the plant gets quiet. If there’s a new conflict, the overtime hours start piling up. People in Independence can almost tell what's happening in the news just by looking at the traffic patterns during shift changes at the plant gates.

What happens to the "Surplus"?

There is a lot of chatter about "Lake City Surplus" in the gun community.

Basically, if a batch of ammo doesn't perfectly meet the military's strict "Mil-Spec" velocity or cosmetic requirements, it gets rejected for military use. But "rejected" doesn't mean it’s bad. It just means it might be 10 feet per second too slow or have a tiny scratch on the brass. This ammo often gets packaged as "XM193" or "XM855" and sold to the civilian market.

It's the gold standard for many shooters.

Why? Because it’s annealed. You can see the rainbow-colored "discoloration" around the neck of the brass. Most commercial ammo is polished to look pretty, but Lake City leaves the annealing marks visible as a sign of strength. It tells the user that the brass is tough and ready for hard use.

Understanding the Contractual Tugs-of-War

When Winchester took over the contract from Northrop Grumman in 2020, it was a massive shift. Winchester (Olin) has a much deeper footprint in the commercial market. This has generally been a win for civilian shooters because Winchester knows how to move product into retail channels efficiently. However, they are still beholden to the Army's oversight.

💡 You might also like: Palantir Alex Karp Stock Sale: Why the CEO is Actually Selling Now

If the Pentagon says "we need X billion rounds for a new stockpile," Winchester has to comply.

This creates a "feast or famine" cycle for 5.56mm availability. If you see the price of ammo spiking, don't just blame the local store. Look at what's happening with the orders coming out of the lake city ammunition plant independence missouri. They set the tide that all other boats float on.

Practical insights for the average person

If you’re looking to understand the impact of this facility or how to navigate the products coming out of it, here are the real-world takeaways.

First, ignore the panic-buy cycles. Yes, Lake City production fluctuates, but it has never fully "gone away" for the civilian market in any permanent capacity. The government likes the revenue generated by selling excess capacity; it helps offset the cost of running the plant.

Second, if you're a reloader, Lake City brass is your best friend. It’s thicker and more durable than most commercial-grade brass. Just remember that military brass has "crimped" primers. You’ll need to swage or ream out that crimp before you can seat a new primer. It’s an extra step, but the longevity of the brass makes it worth it.

Third, keep an eye on the 6.8mm transition. As the military moves away from 5.56mm over the next decade, we might actually see a massive "fire sale" of 5.56mm equipment or surplus as Lake City clears out old inventory to make room for the new standard.

The lake city ammunition plant independence missouri remains the heavy hitter of the American ballistics world. It is a strange hybrid of government bureaucracy, high-output manufacturing, and historical legacy. It isn't going anywhere. Whether you're a taxpayer, a local resident, or someone who just wants reliable ammo for a Saturday at the range, this facility is the silent giant behind the curtain.

Next Steps for Information and Action:

- Verify Headstamps: Check your current ammunition stock. If you see "LC" followed by two numbers (like "LC 23"), that round was manufactured at the Independence plant in 2023.

- Monitor Federal Contracts: For those interested in the business side, follow the Department of Defense "Contracts" page. Look for Olin/Winchester awards specifically tied to the Lake City Army Ammunition Plant (LCAAP) to predict market supply.

- Local Updates: If you live in the Independence or Blue Springs area, monitor the official Army Joint Munitions Command (JMC) website for environmental restoration updates and community meeting schedules regarding land use around the plant.