You’re standing in the middle of a gutted room, hammer in hand, looking at a skeleton of wood. It looks simple. It’s just sticks in a row, right? But then you start measuring, and suddenly the math doesn't feel so straightforward. If you’ve ever wondered why interior wall stud spacing is almost always set at 16 inches, you aren't alone. It’s one of those industry standards that feels like a law of nature, but it’s actually a calculated balance of structural integrity, material waste, and sheer historical habit.

Most people think studs are just there to hold up the drywall. That’s barely half the story.

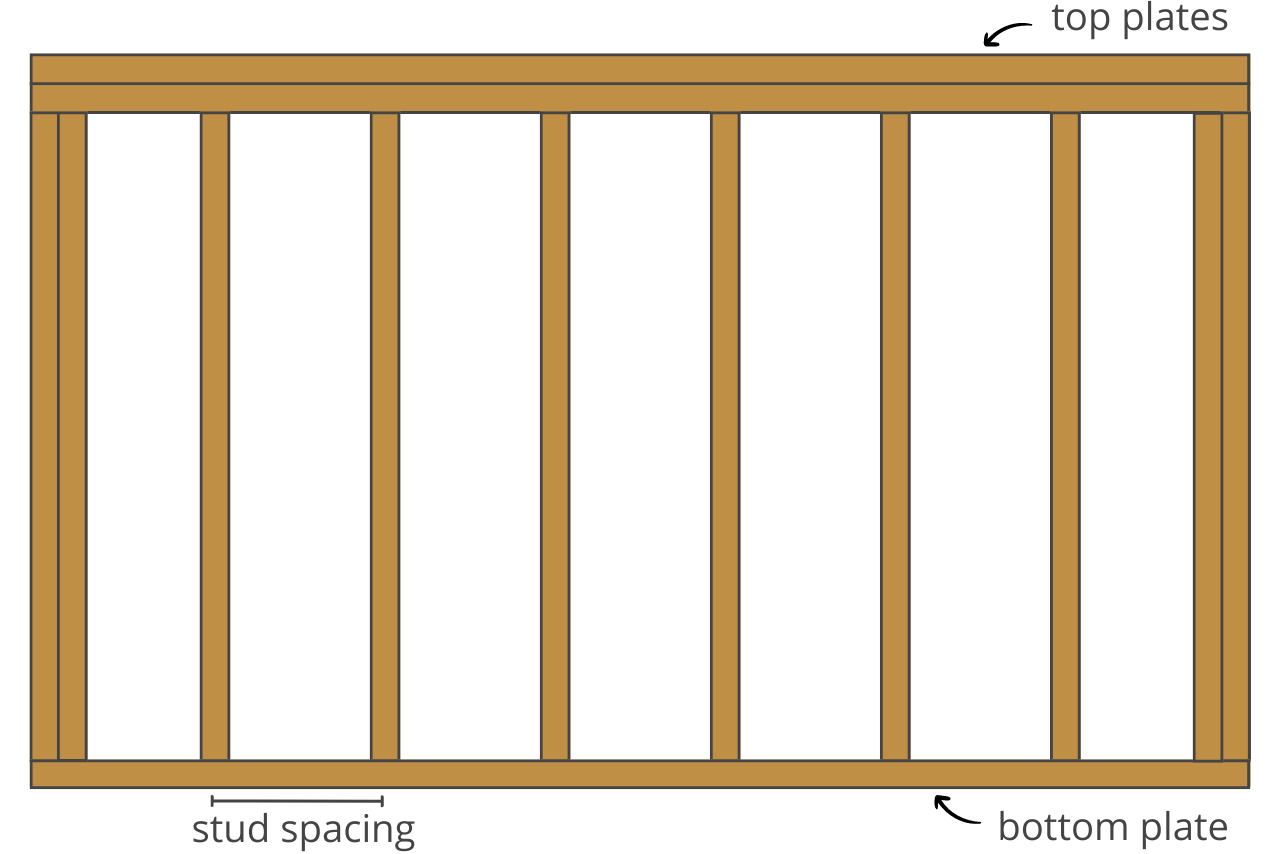

The Magic Number: 16 Inches on Center

When we talk about "16 inches on center" (OC), we mean the distance from the center of one vertical stud to the center of the next. It’s the gold standard for residential construction in North America. Why? Because of the 4x8 sheet. Whether it’s plywood, OSB, or drywall, almost every sheet of building material comes in 4-foot widths.

Do the math. 48 inches (the width of a sheet) is perfectly divisible by 12, 16, and 24.

If you spaced your studs at 17 inches, the edge of your drywall would hang off into dead space. You’d have nothing to nail into. By using 16-inch interior wall stud spacing, a single 4-foot sheet of drywall covers exactly three stud cavities and ends perfectly halfway across the fourth stud. This allows the next sheet to butt up against it and share that same piece of wood for support. It’s elegant. It’s efficient. It’s also surprisingly strong.

The 24-Inch Alternative

Sometimes you'll see 24-inch spacing. This is usually part of "Advanced Framing" or OVE (Optimal Value Engineering). The idea here is to reduce the amount of lumber used, which saves money and—more importantly for some—increases the energy efficiency of the home. Fewer studs mean more room for insulation. In a non-load-bearing interior wall, 24-inch spacing is often perfectly legal under the International Residential Code (IRC).

But there’s a catch.

📖 Related: Finding a Small Space Dining Table Set for 6 Without Cramming Your Room

Wider spacing makes the wall feel... flimsy. If you lean against a wall with 24-inch centers and thin half-inch drywall, you might actually feel it flex. It’s also a nightmare for hanging heavy cabinets or a massive 85-inch TV. You have fewer "anchors" to work with. Honestly, most high-end builders stick to 16 inches even when the code allows for more, just because the finished product feels more "solid" to the homeowner.

Load-Bearing vs. Partition Walls

You have to know what the wall is actually doing before you start spacing things out. A partition wall is just a room divider. It carries its own weight and the weight of the drywall, but that’s it. You could probably build it out of toothpicks if the building inspector wasn't looking (please don't).

Load-bearing walls are different. They are the spine of the house. They carry the weight of the floor above, the roof, and the "live load" of people walking around.

In these cases, interior wall stud spacing isn't just about convenience; it’s about preventing your ceiling from becoming your floor. If a wall is load-bearing, the studs generally need to line up directly under the floor joists or roof rafters above. This is called "stack framing." It creates a direct vertical path for the weight to travel down to the foundation. If your joists are 16 inches apart, your studs better be 16 inches apart too.

Measuring Like a Pro (The "Red Number" Secret)

If you pull out a standard Stanley or Milwaukee tape measure, you’ll notice something. There are little red numbers or diamonds every 16 inches. 16, 32, 48, 64... they're highlighted for a reason.

But here’s where rookies mess up.

If you start your first stud at 16 inches from the corner, your drywall won't line up. You have to account for the thickness of the first stud. Usually, you mark your first stud at 15 1/4 inches, then every 16 inches after that. This ensures that the edge of your first 4-foot sheet of drywall hits the center of the stud perfectly. If you forget that first 3/4-inch offset, you’ll be cutting every single sheet of drywall for the rest of the project. It’s a miserable way to spend a Saturday.

Wood Species and Grade

Not all 2x4s are created equal. Most "stud grade" lumber is Spruce, Pine, or Fir (collectively called SPF). It’s cheap and relatively straight. However, if you're building in a basement where moisture is an issue, you might be looking at pressure-treated plates.

The species of wood actually dictates how much weight a stud can carry. According to the American Wood Council’s Span Tables, a Douglas Fir stud can generally handle more vertical compression than a Hem-Fir stud of the same size. While this rarely changes the interior wall stud spacing (which stays at 16 or 24 for the drywall's sake), it might change whether you need 2x4s or 2x6s.

The "Real World" Problems

Construction is messy. Wood is a natural product. It twists. It bows. It has knots that make it impossible to drive a screw.

- The Crown: Every piece of lumber has a slight curve, called the crown. When you're framing, you have to make sure all the crowns are facing the same direction (usually out). If you mix them up, your wall will look wavy once the drywall is up.

- Twisted Studs: Sometimes a stud looks fine at the lumber yard but turns into a corkscrew once it dries out in your house. If you have a stud that’s badly twisted, it’ll push the drywall out and create a "pop" where the screw head breaks through the paper.

- The Utility Gap: Sometimes you have to move a stud. Maybe a 4-inch drain pipe needs to go exactly where a stud is supposed to be. You can "sister" studs or create a wider cavity, but you have to bridge that gap with a header if it's a load-bearing wall.

Common Misconceptions

People think "more is always better." I've seen DIYers put studs every 12 inches because they wanted a "strong" wall.

It’s overkill.

Using 12-inch interior wall stud spacing adds significant cost and weight without providing much benefit for a standard interior wall. It actually makes running electrical wires and plumbing more difficult because you have more wood to drill through. Plus, it creates more "thermal bridging," which is just a fancy way of saying heat escapes through the wood faster than it does through insulation.

Another myth is that metal studs follow different rules. Nope. Metal studs in commercial buildings are still usually 16 or 24 inches OC. The materials change, but the geometry of a 4x8 sheet of rock doesn't.

The Cost of Getting It Wrong

If you mess up the spacing, the costs compound.

- Material Waste: You’ll end up cutting off 2-3 inches from every sheet of drywall. That adds up to dozens of wasted square feet.

- Labor: Taping and mudding joints that don't land on a stud is a nightmare. The joint will eventually crack because the wall flexes.

- Inspection Failure: If you’re doing permitted work, an inspector will pull out a tape. If they see 18-inch spacing on a load-bearing wall, they’ll make you tear it down. No warnings. No "it's probably fine." Just a red tag and a lot of wasted money.

Practical Steps for Your Project

Before you drive the first nail, you need a plan. Don't just "wing it" based on where you think the wall should go.

- Snap a Chalk Line: Mark your top and bottom plates on the floor and ceiling. This ensures the wall is actually plumb. A wall that's spaced perfectly but leans two inches to the left is still a bad wall.

- Mark Your Plates Together: Lay your top plate and bottom plate side-by-side on the floor. Mark your interior wall stud spacing across both at the same time. This guarantees that your studs will be perfectly vertical.

- Check for Obstructions: Look up. Are there HVAC ducts, wires, or pipes in the way? It’s much easier to shift a wall three inches now than it is to move a main stack later.

- Use a Spacer Block: If you’re working alone, cut a scrap piece of 2x4 to exactly 14 1/2 inches (which is the space between studs set at 16 inches OC). You can use this block to hold the next stud in place while you nail the bottom.

Interior framing is the skeleton of your home. If the skeleton is deformed, everything you put on top of it—the skin, the paint, the cabinets—will show those flaws. Stick to the 16-inch standard unless you have a very specific, engineered reason not to. It’s the industry standard for a reason: it just works.

Essential Checklist for Interior Framing

- Confirm if the wall is load-bearing by checking the joist direction above.

- Select 16-inch OC for standard applications or 24-inch OC for non-load-bearing, eco-friendly framing.

- Use a 15 1/4-inch offset for the first stud to ensure drywall sheets land on center.

- Inspect every stud for "crown" and install them all facing the same direction.

- Double-check local building codes, as some regions have specific requirements for fire blocking in tall walls.

Once the framing is inspected and closed up, you’ll never see these studs again. But you’ll know they’re there every time you hang a picture frame or lean against the wall and it doesn't budge. Precision in the beginning saves a lifetime of drywall cracks later.

🔗 Read more: Wig Glue for Wigs: What Most People Get Wrong About Your Lace Front

Actionable Next Steps

- Identify Load-Bearing Walls: Before any demolition or new construction, go into your attic or crawlspace. If the joists are perpendicular to the wall and "break" over it, that wall is load-bearing.

- Calculate Lumber: For 16-inch spacing, a general rule of thumb is to estimate one stud for every lineal foot of wall. This accounts for corners, doorways, and the inevitable "bad" stud that’s too warped to use.

- Consult the IRC: Download or view the International Residential Code (Section R602) to verify the maximum allowable spacing for your specific wood species and wall height.

- Mark Your Layout: Use a dedicated framing square or a "stud layout tool" to mark your plates quickly and accurately without having to do the math for every single stud.