You’re standing under a deck frame, arms aching, holding a heavy pressure-treated 2x10, and wondering why the heck the metal flange won't sit flush. It’s a classic DIY crossroads. Honestly, most people think about how do you install joist hangers as a simple "bang it in and forget it" task, but that’s exactly how decks end up sagging—or worse, collapsing—five years down the line. I’ve seen seasoned pros take shortcuts that would make a building inspector’s hair turn gray. It isn't just about the metal. It’s about the physics of the load and the specific chemistry of the fasteners you’re driving into that wood.

Let’s get one thing straight: a joist hanger is a masterpiece of structural engineering, provided you don't treat it like a suggestion.

When you’re looking at that shiny galvanized U-shape, you’re looking at the primary point of failure for many outdoor structures. If you miss a single nail hole, you’ve technically voided the engineered load rating of that bracket. Simpson Strong-Tie, the industry titan in this space, doesn't put those holes there for decoration. Each one is a critical component of the shear strength required to keep your floor from bouncing like a trampoline.

The Hardware Trap: Why Your Screws Might Be Dangerous

If you walk away with nothing else, remember this: never use standard gold wood screws or drywall screws in a joist hanger. It’s tempting. They’re fast. They're right there in your pocket. But drywall screws are brittle; they have almost zero shear strength. Under the weight of a hot tub or even a heavy snowfall, the heads will simply snap off. You need structural connector screws or, better yet, the specific nails designated by the manufacturer.

Most hangers require 10d or 16d common nails. But wait—there’s a catch. If you’re using "shorty" nails (1 ½ inch) to avoid poking through the other side of a single header, you are drastically reducing your load capacity unless the hanger is specifically rated for them. For most ledger connections, you want the 2 ½ or 3-inch nails biting deep into the rim joist.

Check the box. Seriously.

📖 Related: Don't Make No Sense: Why This Southern Phrase Actually Makes Perfect Grammar Sense

The label will tell you exactly which fastener diameter and length were used to achieve the advertised weight limit. If you’re working with ACQ pressure-treated lumber, you also need to ensure your hangers are G185 galvanized or stainless steel. The copper in modern treated wood eats through standard zinc coating like acid. It’s a chemical reaction called galvanic corrosion, and it’s a silent deck killer.

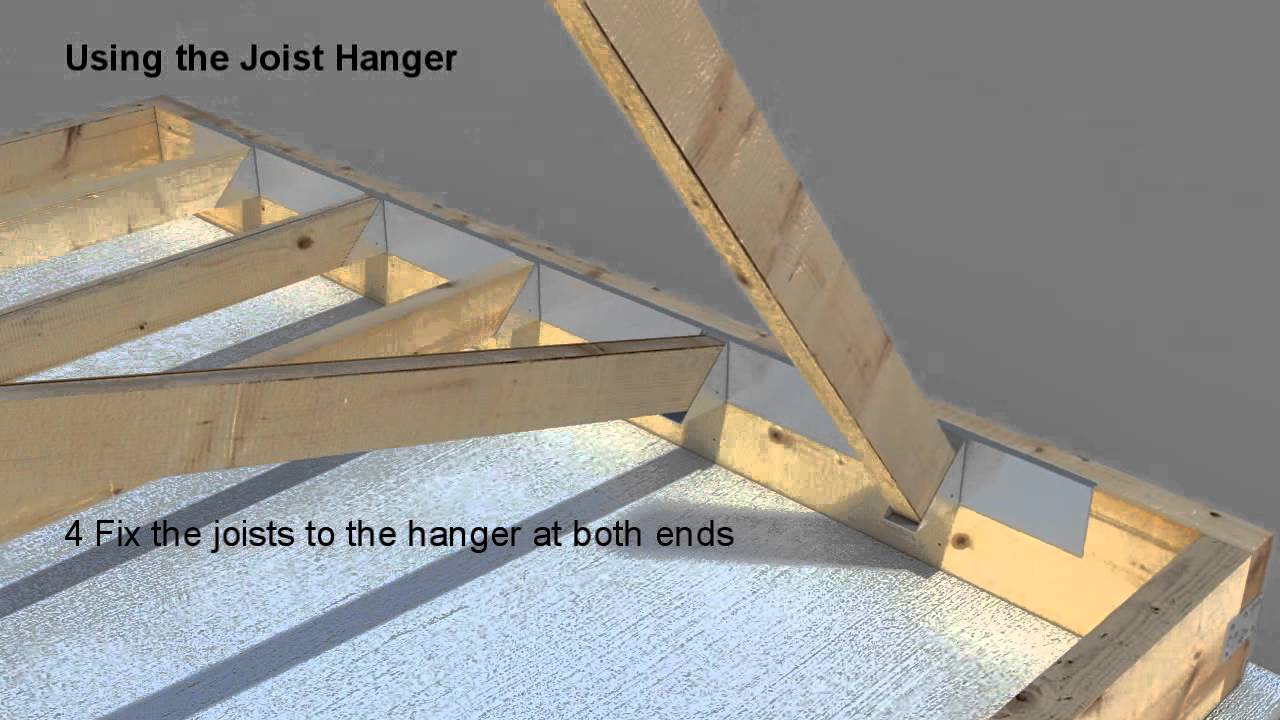

The Real Process of How Do You Install Joist Hangers

Start by T-nailing your joist. This is the "secret" that keeps your sanity intact. Instead of trying to hold the hanger and the wood at the same time, you nail the joist into the ledger board first using two 3-inch nails driven at an angle through the side of the joist into the ledger. This "toenailing" holds the wood in place at the correct height, flush with the top of the beam.

🔗 Read more: Hairstyles for females over 50: What Your Stylist Isn't Telling You

Now, you slide the hanger underneath.

Squeezing and Seating

The hanger should be snug against the bottom of the joist. If there’s a gap at the bottom, the joist will eventually "seat" itself under load, which means your floor will drop a fraction of an inch and start squeaking. Use a scrap piece of 2x material and a hammer to tap the bottom of the hanger tight against the joist before you drive a single nail into the flanges.

🔗 Read more: L'Oréal EverPure Purple Shampoo: How to Kill Brass Without Trashing Your Hair

The Nail Pattern

Start with the header flanges—the parts that touch the ledger board. Drive your nails into the top holes first, then the bottom. This locks the bracket in place. Once the bracket is secured to the wall or beam, move to the "gusset" or "diagonal" holes. These are the ones that go through the hanger, through the joist, and into the ledger at a 45-degree angle. This is called double-shear nailing. It’s the strongest connection possible because the nail is supported by three different layers of material.

Common Mistakes That Fail Inspection

I’ve seen people try to save money by using "concealed flange" hangers where they aren't needed, or worse, using a 2x6 hanger for a 2x10 joist. You can’t do that. The "ears" of the hanger need to extend up at least 60% of the height of the joist to prevent the wood from rotating or splitting along the grain.

- Over-driving nails: If you’re using a pneumatic nailer, turn the PSI down. If the head of the nail crushes the galvanized coating and sinks deep into the steel, you’ve created a spot for rust to start.

- The "Gap" Sin: If your joist is cut too short and there’s a gap wider than 1/8th of an inch between the end of the joist and the ledger, the hanger cannot perform its job correctly. The wood needs to be butt-up tight.

- Missing the Joist Nails: Many beginners nail the hanger to the wall but forget to nail the hanger to the joist itself. Without those side nails, the joist can literally slide out of the "stirrup."

Dealing with Slopes and Odd Angles

Sometimes you aren't building a perfectly flat deck. If you’re working on a ramp or a sloped roof, standard hangers won't work. You’ll need "slopeable" or "skewable" hangers. Don't try to bend a standard 90-degree hanger in a vise to make it fit an angle. You’ll fatigue the metal, create micro-fractures, and the whole thing becomes a liability. Manufacturers like Simpson and MiTek make adjustable versions (like the THASR series) that are designed to be bent once to a specific degree.

Actionable Steps for a Solid Build

- Measure twice, cut once: Ensure the joist is flush with the top of the carrying beam. A joist that sits too high will create a hump in your decking.

- Acquire the right "Techo" nails: Buy a box of 1 ½ inch and 2 ½ inch structural connector nails. Use the long ones for the header and the short ones for the joist sides if you’re worried about blowout.

- Check for "Crown": Always install the joist with the "crown" (the slight upward bow) facing up. The weight of the floor will eventually flatten it out.

- Seal the End Grain: Before you slide that joist into the hanger, paint the cut end with a wood preservative or a bit of joist tape. The hanger acts like a cup that holds moisture; sealing the wood prevents rot where you can't see it.

- Use a Palm Nailer: If you’re working in tight spaces between joists, a hammer is a nightmare. A pneumatic palm nailer is a $50 tool that will save your knuckles and ensure every nail is driven perfectly straight.

If you follow these steps, your structure will be rock solid. You won't have to worry about the "bounce" when people walk across the room, and you certainly won't have to worry about the building inspector telling you to tear it all down and start over. Get the right metal, use the right nails, and never, ever trust a drywall screw with your structural integrity.