You’re staring at a plastic stick with a bunch of tiny black lines and wondering why something so simple feels so confusing. Honestly, it happens to the best of us. Whether you are trying to figure out the diameter of a screw for a DIY home repair or checking the thickness of a guitar pick, knowing how to measure mm on a ruler is one of those basic life skills that we often assume we know until we actually have to do it accurately.

The metric system is beautiful because it’s logical. It’s all based on tens. But when you’re looking at a standard ruler, those tiny slivers of space between the numbers can start to blur together.

What exactly is a millimeter anyway?

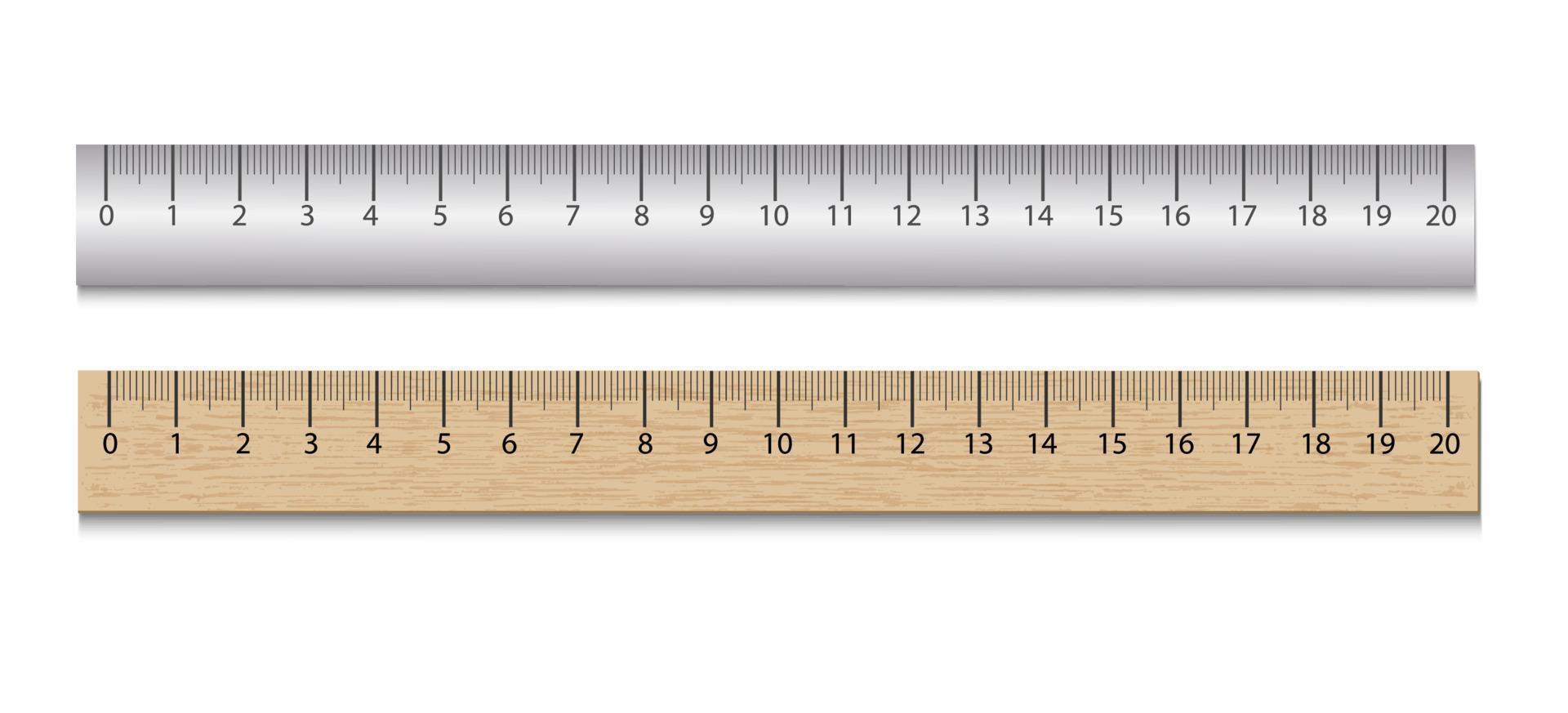

Let’s get the scale right. A millimeter is tiny. Think about the thickness of a standard credit card or a dime. That’s roughly 1 mm. If you look at your ruler, you’ll see long lines with numbers—those are centimeters. In between those centimeters, there are ten smaller graduation marks. Each one of those individual gaps represents exactly one millimeter.

Because $1 \text{ cm} = 10 \text{ mm}$, the math is pretty straightforward, but the physical act of measuring requires a steady hand and a bit of "parallax" awareness. Parallax is just a fancy word for the error you get when you look at the ruler from an angle. If you aren't looking straight down at the mark, you're going to be off by a millimeter or two, which, in the world of precision, might as well be a mile.

How to measure mm on a ruler step by step

First things first. Find the zero.

It sounds stupidly simple, but this is where most people fail. On many cheap school rulers or old wooden ones, the "zero" isn't actually the very edge of the physical object. There is often a little bit of "dead space" or a "buffer" before the first line starts. If you butt the edge of the ruler up against your object, you’ve already added 1 or 2 millimeters of error. Always align the start of the object with the actual line marked "0" or the first long line on the scale.

Once you’ve lined up the zero, look at where the object ends.

Count the whole centimeters first. If your object passes the 3 cm mark, you already know you have at least 30 mm. Now, count the tiny ticks after that 3. If there are four tiny ticks, you add them to the 30.

Total? 34 mm.

The trick with the "halfway" mark

Most rulers have a slightly longer line exactly in the middle of two centimeter marks. That’s the 5 mm mark. It’s there so you don’t have to count "one, two, three, four, five" every single time. It's a visual anchor. If your object ends just one tick past that medium-length line, you know it's 6 mm past the centimeter mark. It saves your eyes from a lot of strain.

Precision matters here.

If you're using a ruler for something like a medical application—say, measuring the diameter of a skin lesion as suggested by the American Academy of Dermatology—being off by a millimeter matters for tracking growth. For a craft project? Maybe not so much. But get in the habit of being exact.

Common mistakes that ruin your measurement

Let's talk about the "end-of-ruler" problem again because it's the biggest culprit in bad data. Over time, the corners of rulers get rounded off. If you use the physical end of a worn-down ruler as your starting point, your measurement is essentially a guess.

Another big one: the thickness of the ruler itself.

📖 Related: Hourly Weather Paterson NJ: What You Actually Need to Know for Today

If you’re measuring something flat on a table, and your ruler is a thick piece of plastic, there’s a gap between the markings and the object. This is where that parallax error I mentioned earlier really bites you. To get around this, some pros actually turn the ruler on its side (on its "edge") so the markings are physically touching the object. It feels a bit clunky at first, but it eliminates the visual gap.

Why mm is better than inches for DIY

Inches are messy. Dealing with 1/16ths or 1/32nds of an inch requires a lot of mental gymnastics. Metric is just counting. If you're working on a 3D printing project or trying to fit a new RAM stick into a laptop, everything is standardized in millimeters. Knowing how to measure mm on a ruler allows you to communicate with manufacturers and hardware stores globally without having to convert fractions in your head.

Tools of the trade: When a ruler isn't enough

Sometimes a ruler just won't cut it. If you need to measure something round, like a pipe or a piece of jewelry, a flat ruler is the wrong tool. You'll end up guessing where the "peak" of the curve is.

In these cases, people use calipers. Digital calipers give you a reading down to 0.01 mm. But for most of us, a high-quality stainless steel ruler (often called a "machinist's rule") is the gold standard. Steel rulers are better than plastic because the lines are etched into the metal. They don't rub off, and the edges don't warp over time.

Reading the "hidden" millimeters

What if the object falls between two millimeter marks?

✨ Don't miss: The Philly Naked Bike Ride: Why Thousands of People Actually Do This Every Year

On a standard ruler, you can't officially measure half a millimeter. However, you can "estimate the last digit." If the edge of your paper is halfway between the 7 mm and 8 mm mark, you'd record it as 7.5 mm. Just know that the ".5" is an estimate. In scientific communities, like those following NIST (National Institute of Standards and Technology) guidelines, that last estimated digit is still considered significant, even if it's not 100% certain.

Practical applications and "Real World" mm

Think about the small things in your house.

A standard pencil lead is usually 0.5 mm or 0.7 mm. Look at those tiny lines on your ruler again. That's how small we're talking. When you understand the scale, you start seeing the world differently. You realize that a 3 mm gap in a car's door panel is actually a huge manufacturing flaw, or that a 1 mm difference in a shoe insert can be the reason your foot hurts.

To get better at this, practice with items of known sizes.

- A standard US nickel is exactly 1.95 mm thick (basically 2 mm).

- A SD card is 24 mm wide.

- A bottle cap is usually around 30 mm in diameter.

Measuring these "calibration" objects helps train your eyes to recognize distances without even looking at the numbers.

Getting the most out of your ruler

If you're looking to buy a ruler specifically for mm measurements, look for one that has "zero-glare" finish. Stainless steel is great, but if it’s too shiny, the reflection of your overhead lights will make those tiny mm ticks disappear. A satin or matte finish is much easier on the eyes. Also, check if the markings start at the very edge or if there’s a lead-in. Both are fine, you just need to know which one you’re holding.

Once you master the alignment and the "count-by-tens" logic, measuring in millimeters becomes second nature. It's faster than imperial, more precise for small objects, and universally understood.

✨ Don't miss: When Was the First One Dollar Bill Printed? The Real History Might Surprise You

Actionable Next Steps

Check your current ruler right now. Look at the very end—does the "0" line start at the physical edge or is it indented? This is the most important thing to know about your tool. Next, try measuring a credit card. It should be exactly 85.6 mm long. If you get 85 or 86, you’re doing great. If you get 83, you’re likely starting from the physical edge of the ruler instead of the zero line. Practice this alignment five times with different small objects around your desk to lock in the muscle memory.