Building steps is arguably the most intimidating part of any deck project. Honestly, it’s where most DIYers throw in the towel and call a contractor. You’re dealing with the "rise," the "run," and the haunting possibility that your stairs will feel like a funhouse ladder if you’re off by even a quarter-inch. But here’s the thing about how to make porch stairs: it’s just math and muscle.

If you can use a circular saw and a framing square, you can do this.

Most people mess up before they even buy the wood. They head to the big-box store, grab some 2x12s, and start cutting based on a "gut feeling" or a YouTube video they watched once. Don't do that. The secret to stairs that actually last twenty years isn't just the wood—it's the geometry. You have to account for the thickness of your treads and the height of your finished landing. If you forget that your 2x12 tread adds an extra 1.5 inches to the top step but subtracts it from the bottom, you’re going to trip every single time you walk into your house. It's a literal trip hazard.

The Math Everyone Gets Wrong

First, find your total rise. This is the vertical distance from the top of the porch surface to the ground where the stairs will land. Use a straight board and a level to get this right. If your ground is sloped, measure to the exact spot where the bottom of the stairs will rest, not just "somewhere near the porch."

Let's say your total rise is 35 inches. You want each individual step (the riser) to be around 7 inches. This is standard IRC (International Residential Code) stuff. Divide 35 by 7, and you get 5 steps. Easy, right? But what if your rise is 38 inches? 38 divided by 7 is 5.42. You can't have 5.42 steps. You divide 38 by 5 to get 7.6 inches per step, or divide by 6 to get 6.3 inches. Stay between 6 and 7.75 inches to keep it legal and safe.

Why the Bottom Step is Shorter

This is the "aha!" moment for most builders. When you cut your stringer—that’s the zigzaggy structural part—the bottom riser must be shorter than the rest by the exact thickness of your tread material. If you're using 2x12 treads, which are 1.5 inches thick, you must cut 1.5 inches off the bottom of the stringer. Why? Because when you nail that tread on top, it adds 1.5 inches back. If you don't do this, your bottom step will be 8.5 inches high and your top step will be 5.5 inches. You'll stumble. Every. Single. Time.

Choosing the Right Wood and Tools

Pressure-treated lumber is the standard. Specifically, look for "Ground Contact" rated 2x12s for your stringers. Even if your stairs aren't literally buried in the dirt, they are close to it. Moisture bounces off the ground and rots out the bottom of stringers faster than any other part of a deck.

✨ Don't miss: The Long Haired Russian Cat Explained: Why the Siberian is Basically a Living Legend

- The Framing Square: Get one. You can't do this with a tape measure alone.

- Stair Gauges: These are little brass knobs that clamp onto your square. They are cheap, maybe five bucks, and they ensure every single cut is identical.

- A Sharp Circular Saw: Use a new blade. A dull blade burns the wood and wanders off your line.

- A Hand Saw: You'll need this to finish the "inside" corners of your stringer cuts where the circular saw blade can't reach without over-cutting.

Over-cutting is a massive mistake. If you run your circular saw past the corner to finish the cut, you've just created a "stress riser." You've basically scored the wood, making it prone to snapping under a heavy load. Stop the circular saw just short of the line and finish the job by hand. It takes an extra minute, but it keeps the stringer strong.

Cutting the Stringers

Layout is everything. Clamp those stair gauges onto your framing square—one at the riser height (say, 7 inches) and one at the tread depth (usually 10 or 11 inches). Place the square on your 2x12 and trace the zigzag. You’ll want at least three stringers for a standard 36-inch wide staircase. If you're going wider, or using composite decking like Trex or Azek, you might need stringers spaced every 12 inches because composite is "floppier" than wood.

The Landing Pad

Do not just set your stairs on the grass. The wood will suck up moisture like a straw, and within three years, the bottom will be mush. You need a solid landing. A concrete pad is best, but you can also use heavy pavers set on a bed of compacted gravel.

Some guys like to bolt a "kick plate" or "landing cleat" to the concrete. This is basically a piece of pressure-treated 2x4 that you power-nail into the concrete. The notches at the bottom of your stringers hook over this plate. It prevents the stairs from sliding outward over time. Gravity is a constant force; help your stairs fight it.

Attaching to the Porch

How you hook the stairs to the house determines if they'll stay put during a party with twenty people on them. Do not just "toenail" the stringers into the rim joist. That’s bush league.

- Stair Hangers: These are specialized metal brackets. They cradle the bottom of the stringer and nail into the deck frame.

- Long Ledger: Some builders extend the stringers up behind the rim joist and bolt through both. This is incredibly strong but requires more planning.

- The Cleat Method: Nail a 2x4 or 2x6 level across the rim joist and let the stringers rest on it, then use structural screws to pull everything tight.

Structural screws (like GRK or TimberLOK) are your best friends here. They have massive shear strength compared to standard gold screws or nails. Use them.

🔗 Read more: Why Every Mom and Daughter Photo You Take Actually Matters

Treads and Risers

Once your stringers are mounted and level—double-check that they are level across the width—it’s time for the "skin."

You can use 2x12s for treads, but I prefer using two 2x6s with a small gap between them. This allows water to drain through. Standing water is the enemy. If you use a solid 2x12, it will eventually cup, holding a puddle of water right in the middle where you walk.

Don't skip the risers. The vertical boards (risers) aren't just for looks. They close the gap to keep critters out from under the porch, and more importantly, they add significant lateral stiffness to the whole structure. They turn three individual stringers into one solid unit. Use 1x8 cedar or PVC trim for a clean, professional look.

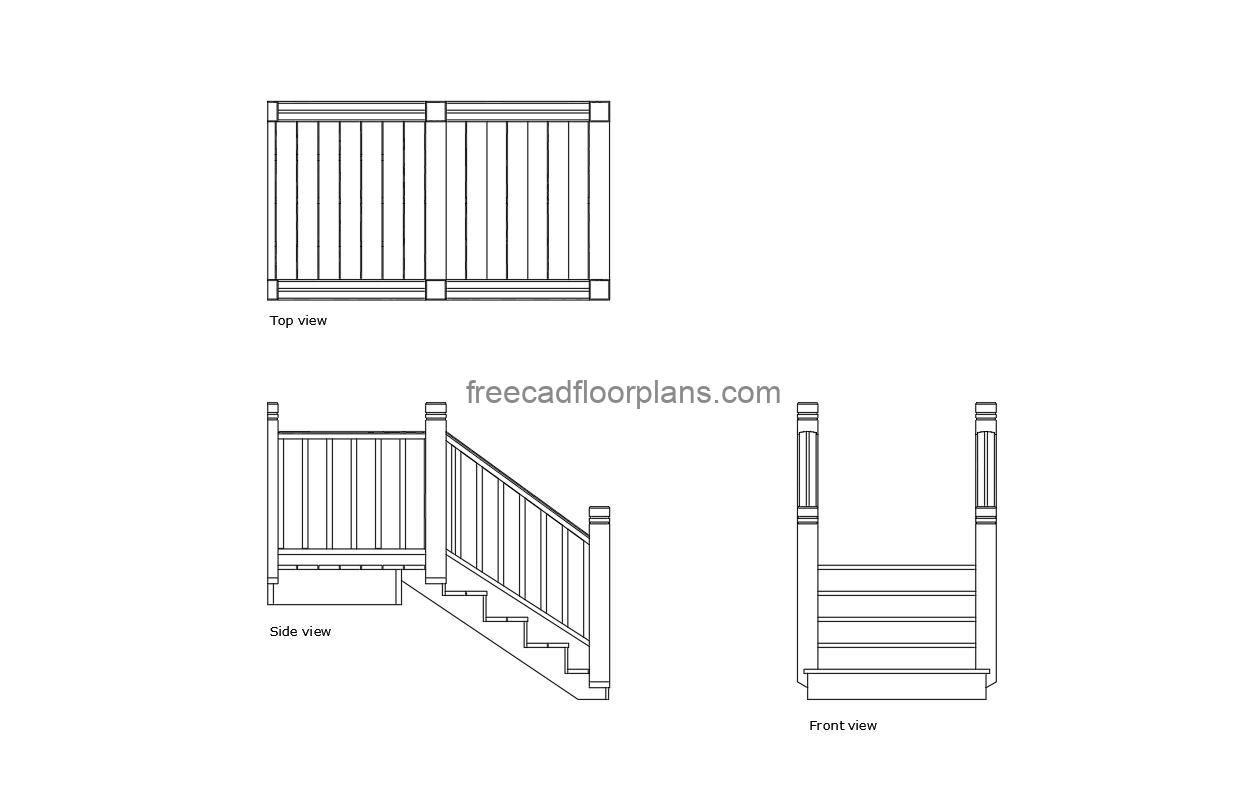

The Guardrail Requirement

In most jurisdictions, if your stairs have more than three "risers" (meaning four or more steps), you legally need a handrail. This isn't just a suggestion from a bored inspector. It's about safety.

The handrail needs to be "graspable." A 2x4 laid flat is not graspable. You want a dedicated handrail profile that a person can actually wrap their fingers around if they slip. The height should be between 34 and 38 inches above the "nosing" (the front edge) of the steps.

Pro Tips for Longevity

Apply joist tape to the top of your stringers before you screw down the treads. This is a butyl-based waterproof tape. It seals the holes made by your screws and prevents water from seeping into the end grain of the stringer. It’s a ten-minute step that can double the life of your stairs.

💡 You might also like: Sport watch water resist explained: why 50 meters doesn't mean you can dive

Also, use stainless steel or high-quality coated screws. Cheap screws will react with the copper in pressure-treated wood and corrode within a few seasons. You'll see those ugly black streaks on the wood—that's the screw literally dissolving.

Common Misconceptions

People think more stringers are always better. While you don't want a "bouncy" step, over-crowding stringers can actually make it harder to get proper airflow, leading to rot. Stick to 16-inch centers for wood and 12-inch centers for composite.

Another myth is that you need to "bury" the bottom of the stringers for stability. No. Never bury wood in dirt if you can avoid it. Even "ground contact" wood will fail eventually. Keep the wood on top of concrete or stone.

Next Steps for Your Project

Start by measuring your total rise today. Don't guess. Use a long level and a tape measure. Once you have that number, use a calculator to figure out your riser height.

Before you buy any lumber, sketch your stringer layout on a piece of cardboard or a scrap of plywood. It’s a lot cheaper to realize you made a math error on a piece of trash than on a $40 piece of 2x12 lumber.

Once your plan is solid, check your local building codes. Some towns have very specific rules about "tread nosing" (how much the top board hangs over the riser) or specific railing heights. Getting it right the first time saves you the nightmare of tearing it all down after an inspection.

Buy your lumber a few days early and let it sit on-site. Pressure-treated wood is often "wet" and heavy from the factory. Letting it air out a bit can help prevent warping after you've already made your cuts. Grab your framing square, some brass gauges, and a box of structural screws. You're ready to start.