You’re tired of the tinny, plastic sound coming from that $30 "waterproof" puck you bought on a whim. We’ve all been there. You want something with actual kick, something that doesn't vibrate off the table when the bass hits. But looking at high-end DIY kits can be intimidating. Honestly, learning how to build a bluetooth speaker is less about being an electrical engineer and more about understanding how air moves through a box. If you can use a screwdriver and a soldering iron—or even just some crimp connectors—you can beat the sound quality of most mid-range store-bought units for half the price.

The secret isn't in the magic of the Bluetooth chip. It’s the physics of the enclosure. Most people think they need the most expensive drivers to get good sound, but even a pair of $15 Dayton Audio or Peerless drivers will sound incredible if the cabinet is braced and sealed correctly. If you put a $200 driver in a leaky, thin cardboard box, it's going to sound like a megaphone. We’re going to avoid that.

What Actually Goes Into a DIY Speaker?

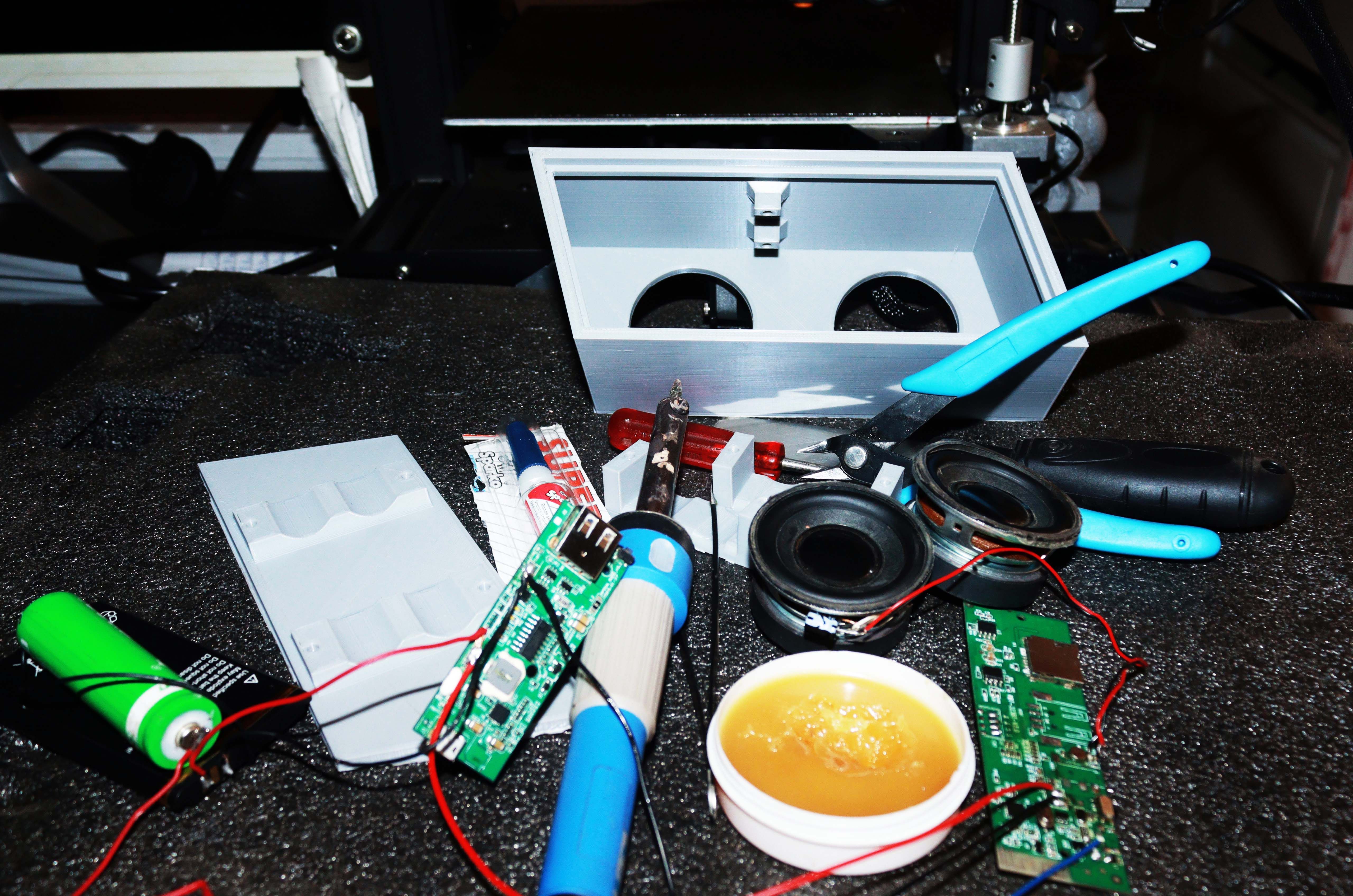

Let's talk parts. You need four main pillars: the drivers (the speakers themselves), the amplifier board, the power source, and the enclosure.

Most beginners make the mistake of buying "full-range" speakers and expecting them to handle sub-bass. They won't. If you want that deep, chest-thumping sound, you're looking at a 2.1 system—two small drivers for the highs and mids, and one dedicated woofer. But for your first build? Stick to a 2.0 setup with two high-quality full-range drivers. It simplifies the wiring immensely.

The amplifier is the brain. For a portable build, you want a Class D amplifier. Why? Efficiency. Class D amps like the TPA3116D2 chips found on many inexpensive boards from parts-express.com or Amazon are roughly 90% efficient. They don't get hot, and they don't eat your battery for breakfast. Many of these boards now come with Bluetooth 5.0 integrated right onto the PCB. This is a lifesaver. It eliminates the need for separate ground loop isolators which often cause that annoying buzzing sound when you share a power source between a Bluetooth module and an amp.

The Enclosure: Where the Magic (and the Math) Happens

This is the part that scares people away. "I’m not a woodworker," you say. Fine. You don't have to be. While MDF (Medium Density Fiberboard) is the gold standard for speakers because it's dense and doesn't vibrate, you can repurpose almost anything. Old ammo cans, vintage suitcases, or even thick PVC pipes.

However, size matters. Every speaker driver has a set of "Thiele/Small parameters." These are basically the speaker's DNA. They tell you exactly how many liters of air the speaker needs behind it to perform optimally. If the box is too small, the bass will be "choked" and tight. Too large, and the speaker loses control, sounding muddy and potentially damaging itself at high volumes.

You've got two main choices:

👉 See also: The Adobe Creative Cloud CC Crack Problem: Why It’s Not Just About Free Software Anymore

- Sealed Enclosures: Easiest to build. Very forgiving. The air inside acts like a spring, helping the speaker cone return to its neutral position. You get very accurate, "punchy" bass but less overall volume.

- Ported Enclosures: These have a tube (a port) that lets air out. This uses the back-wave of the speaker to reinforce the low end. It’s louder and deeper, but if you get the port length wrong, it'll sound like a one-note wonder.

If you’re just starting out, go sealed. Stuff the box with some poly-fill (the fluff inside pillows) to "trick" the speaker into thinking the box is about 15-20% larger than it actually is. It smooths out the response.

Powering Your Creation

Don't just duct tape some AA batteries together. Please.

Lithium-ion is the way to go. Most DIY Bluetooth amps want between 12V and 24V. A 3S (three cells in series) or 4S (four cells) 18650 battery pack is the sweet spot. You will need a BMS (Battery Management System). This is a tiny circuit board that sits between your batteries and the charger. It prevents the batteries from exploding, which is generally considered a "pro-tip" in the hobby.

A 12V system is great for portability. If you want more "headroom"—the ability to play loud without distortion—aim for 19V or 21V. Most laptop power bricks are 19V and make perfect stationary power supplies for these projects.

Building the Thing: A Step-by-Step Reality Check

First, test everything on your desk before you put it in the box. Seriously. Connect the speakers to the amp, hook up the battery, and pair your phone. If it smokes now, it's easy to fix. If it smokes once it's epoxied into a wooden box, you're going to have a bad day.

When you're ready to assemble, focus on the seal. Air leaks are the enemy of sound quality. Use wood glue—generously. Use silicone caulk around the wire holes. Use gaskets behind the speakers. If air is escaping from anywhere except the port, your bass will vanish.

Wiring is the next hurdle. Keep your signal wires (the ones carrying the music) away from your power wires. Electricity creates magnetic fields, and if those fields interfere with your audio signal, you get a "hum." It’s a low, 60Hz annoyance that will ruin a quiet acoustic track. Twist your speaker wires together; this "twisted pair" technique naturally cancels out some electromagnetic interference.

💡 You might also like: When Were VR Headsets Invented? The Truth Might Surprise You

Dealing With the "Bluetooth Buzz"

If you hear a high-pitched whine that changes when you touch your phone or change tracks, you have a ground loop. This happens because the Bluetooth chip and the Amp chip are "fighting" over the ground connection. The easiest fix? Use a dedicated Bluetooth amp board where both are integrated. If you're using separate modules, you'll need a $10 ground loop isolator on the 3.5mm line between them.

Why DIY Beats the Big Brands

You might wonder why you'd bother when you can buy a JBL or a Bose. The answer is repairability and "the curve." Major brands use DSP (Digital Signal Processing) to "fake" bass. They push small speakers past their limits and use limiters to keep them from blowing up. It sounds "okay" at low volumes but gets thin and shouty when you crank it.

When you build a bluetooth speaker, you can use larger, higher-quality drivers that don't need electronic trickery to sound good. Plus, when the battery inevitably dies in three years, you can just swap out the 18650 cells for $15 instead of throwing the whole unit in a landfill.

Common Pitfalls to Avoid

- Thin Walls: If you're using wood, don't use anything thinner than 1/2 inch. Thin walls vibrate, and vibration is energy that should be going into the air as sound, not into the wood as heat.

- No Bracing: If the box is large, glue a small scrap of wood across the middle to connect the front and back panels. It stiffens the whole structure.

- Poor Soldering: Cold solder joints (where the solder looks dull and grainy) will crack over time due to the vibrations of the speaker. Use plenty of heat and make sure the solder flows like water.

- Ignoring Heat: While Class D amps are efficient, they still need some breathing room. Don't wrap the amp in foam insulation.

The Actionable Roadmap

If you're ready to start, don't buy "random" parts. Follow these steps to ensure success:

- Select your drivers first. Look at the Dayton Audio TCP115-4. It’s a 4-inch woofer that punches way above its weight class. Pair it with a small silk dome tweeter if you're feeling fancy, or just use a pair of ND91-4 full-range drivers for a simpler build.

- Pick an Amp. The Dayton Audio KAB series is incredible for beginners. They have plug-and-play wiring harnesses, so you don't even have to solder if you don't want to. They also have integrated Bluetooth and optional battery boards.

- Calculate your volume. Use a free tool like WinISD or an online volume calculator. For two ND91-4 drivers, you're looking at a roughly 3 to 4-liter enclosure.

- Seal it tight. Use a "gasket tape" or even a thin bead of blue tack between the speaker frame and the wood.

- Finish the exterior. Once it sounds good, sand the wood up to 220 grit and apply a simple wipe-on poly or some Tolex (the vinyl stuff on guitar amps) for a professional look.

Building your own gear is addictive. You'll start noticing the flaws in every other speaker you hear. But more importantly, you'll have a piece of hardware that is uniquely yours, sounds better than the mass-produced competition, and is built to last a decade rather than a season.

Take your time with the enclosure. It is the most important "component" in your signal chain. A solid, airtight box is the difference between a hobby project and a high-fidelity piece of audio equipment. Once the glue dries and the first track hits, the effort becomes worth it instantly.