You’re probably looking at a screen right now, wondering if it's finally time to pull the trigger. Maybe you saw a TikTok of a guy printing a functional wrench or a hyper-realistic Mandalorian helmet and thought, "I need that." But the price tags are all over the place. You see one machine for $160 on a flash sale and another that costs as much as a used Honda Civic. It's confusing. Honestly, the question of how much is a 3D printer doesn't have a single answer because the "sticker price" is usually a lie.

I’ve spent years tinkering with these machines, from the early days of smelling burnt plastic in my garage to using high-end industrial systems. Here is the reality: you can get started for less than the cost of a new gaming console, but the rabbit hole goes deep.

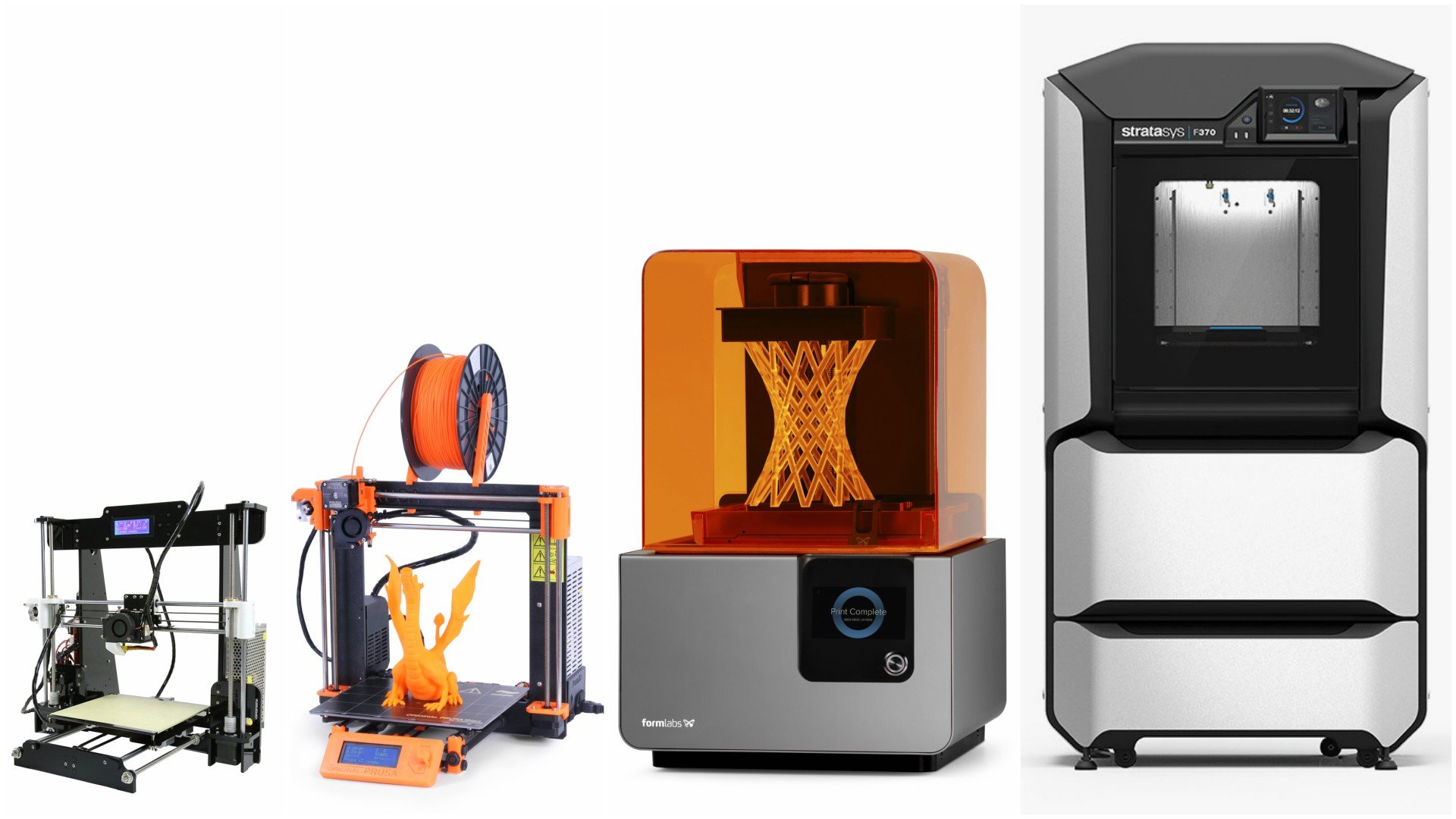

The cheap seats: Entry-level FDM printers

If you just want to mess around, you're looking at FDM (Fused Deposition Modeling). These are the ones that use spools of plastic filament. Basically, it’s a high-tech hot glue gun attached to a robot arm.

For a basic, reliable starter machine like the Creality Ender 3 V3 SE or a Bambu Lab A1 Mini, you are looking at roughly $180 to $300. These machines are lightyears ahead of what we had five years ago. You used to have to spend hours "leveling the bed" with a piece of paper and a prayer. Now? Many of these budget kings have auto-leveling. It's almost plug-and-play. Almost.

But wait. Don't just look at the machine. You need filament. A standard 1kg spool of PLA (Polylactic Acid) costs about $20. You’ll probably want three colors. Add another $60. Then you need a scraper, maybe some isopropyl alcohol for cleaning the bed, and perhaps a 3D Lac or glue stick if things aren't sticking. Suddenly, your $200 printer is a $300 hobby.

Mid-range workhorses: When you want speed

Maybe you're not a tinkerer. You just want the thing to work. This is where the market has shifted massively thanks to companies like Bambu Lab and Prusa Research.

If you want a machine that prints four times faster than the budget options and rarely fails, you’re stepping into the $600 to $1,200 range. The Bambu Lab P1S or the Prusa MK4 are the gold standards here. These machines are incredible. They have enclosures (great for keeping heat in and cats out) and can handle tougher materials like PETG or even ASA.

📖 Related: Finding the Right Silver Apple Watch Band Without Getting Scammed by Cheap Alloys

I recently talked to a guy who runs a small Etsy shop making custom cookie cutters. He started with one $200 machine but quickly realized he spent more time fixing it than printing. He upgraded to a $1,000 enclosed unit. His throughput tripled. For him, the answer to how much is a 3D printer was "enough to save my sanity."

Resin printers: The detail kings

Then there's the messy side of the family. Resin (SLA/MSLA) printing. If you want to print miniatures for Dungeons & Dragons or high-detail jewelry prototypes, FDM plastic won't cut it. You need liquid resin cured by UV light.

The printers themselves are actually pretty cheap. You can grab an Anycubic Photon or an Elegoo Mars for $200 to $400.

But here is the catch—and it’s a big one. Resin is toxic. You need:

- Nitrile gloves ($15 per box).

- A respirator mask ($30).

- A "Wash and Cure" station ($100-$150).

- Gallons of Isopropyl Alcohol ($30+).

- Proper ventilation (sometimes hundreds of dollars for a grow tent and fan setup).

If you buy a $250 resin printer and don't spend another $300 on safety and processing gear, you’re doing it wrong. Don't skimp here. Your lungs will thank you.

The hidden costs nobody mentions

Let's talk about electricity. A 3D printer isn't a huge power hog, but if it’s running 24/7, you’ll notice a small bump in your utility bill—maybe $5 to $15 a month depending on your local rates.

👉 See also: How High Do Aeroplanes Fly? The Real Reason Pilots Love the Sweet Spot

Then there’s software. Most "slicing" software (the stuff that turns a 3D model into instructions for the printer) is free, like Cura or PrusaSlicer. But if you want to design your own complex parts, you might eventually look at Fusion 360. While there is a free personal version, the professional subscription is roughly $490 per year.

And parts wear out. Nozzles clog. Brass nozzles are cheap—$2 each. But if you want to print carbon-fiber-filled filament, you need a hardened steel nozzle. That’s $20 to $50. Build plates get scratched. Fans die. Budget at least **$50 a year** for "oh crap" moments.

Professional and Industrial levels

If you’re a business, you aren't looking at hobbyist gear. You need "uptime."

Professional machines from Markforged or Ultimaker start around $4,000 and can easily hit $20,000. Why? Because they print in continuous carbon fiber or high-temp plastics like PEEK that could literally replace metal parts in an engine.

At the very top end, we’re talking about metal 3D printers. These use lasers to melt titanium or stainless steel powder. You aren't putting one of these in your spare bedroom. These machines, from brands like Desktop Metal or EOS, start at $100,000 and go up into the millions. They require dedicated facilities, inert gas supplies, and specialized technicians.

Is it actually worth it?

Honestly, it depends on your "why."

👉 See also: Music Apps for Android Free Download: What Most People Get Wrong

If you want to save money by printing things you’d normally buy at the hardware store... well, you probably won't. It's almost always cheaper to buy a plastic bracket at Home Depot for $2 than to design, test, and print one.

But if you want to create something that doesn't exist, the value is infinite. Being able to go from an idea in your head to a physical object in your hand within three hours is basically magic.

Practical Next Steps

Before you drop any cash, do these three things:

- Download a Slicer: Download Bambu Studio or PrusaSlicer (both free). Find a 3D model on Printables or Thingiverse and "slice" it. It will tell you exactly how much filament the print uses and how long it will take. This gives you a feel for the workflow without spending a dime.

- Check your space: Do you have a desk that doesn't wobble? A wobbly desk ruins prints. Do you have a window nearby for ventilation?

- The $500 Rule: If you are buying your first FDM printer, have $500 ready. Spend $300 on the machine and keep $200 for filament, tools, and the inevitable replacement parts. If you're going resin, make that $600 to account for the extra safety gear.

Start with PLA filament. It's the most forgiving, it doesn't smell bad, and it’s biodegradable-ish. Once you've mastered that, then you can start looking at the fancy, expensive stuff. 3D printing is a marathon, not a sprint. Enjoy the process of learning how to fix what you break.