When you look at the Dubai skyline, your eyes just sort of stop at the Burj Khalifa. It’s unavoidable. It’s also incredibly hard to wrap your head around the fact that humans actually built something that reaches $828$ meters into the clouds. But beyond the shimmering glass and the world records, there is a massive pile of receipts.

So, how much did it cost to make the Burj Khalifa?

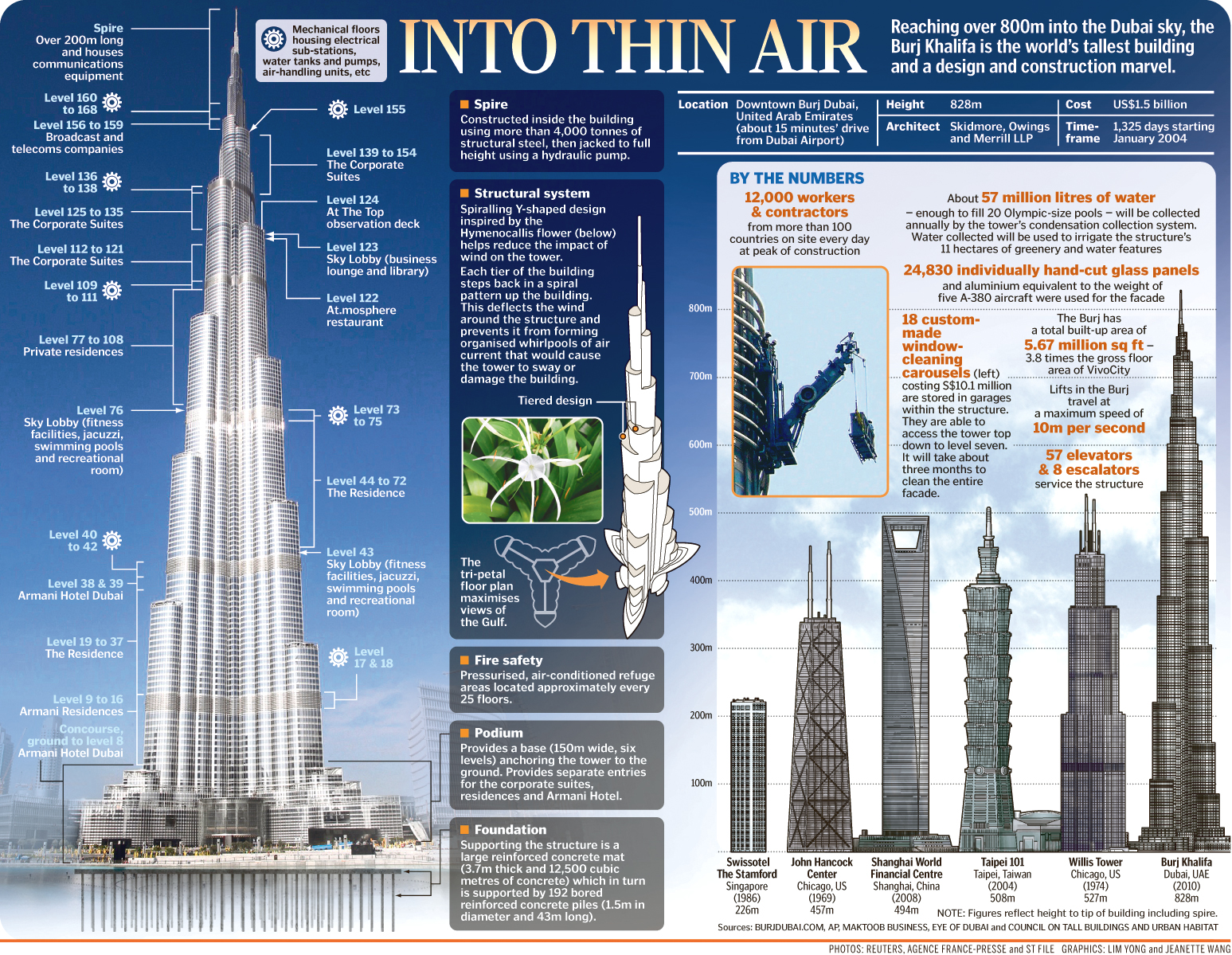

If you’re looking for a quick number, it’s $1.5 billion. Honestly, in a world where tech companies burn through that much in a fiscal quarter and stadium renovations can top $2 billion, that price tag feels… surprisingly low? Or maybe we’ve just lost all sense of what a billion dollars actually buys.

But that $1.5 billion figure doesn't tell the whole story. It doesn't cover the "Dubai Shock" of 2008, the late-night name change that saved the project from bankruptcy, or the sheer amount of ice it takes to keep the place from melting in the desert heat.

The Original $876 Million Dream

Believe it or not, the Burj Khalifa was originally supposed to be a "budget" project—at least by Dubai standards. The initial estimates sat around $876 million.

📖 Related: Why the Dow Jones Real Time Ticker Still Matters When Everything Else Feels Like Chaos

Emaar Properties, the developer behind the tower, had a plan. They wanted a centerpiece for a new $20 billion development called "Downtown Dubai." The tower itself was meant to be the loss leader—the shiny thing that attracted investors to the surrounding apartments and malls.

Then, things got complicated.

The design changed. A lot. Adrian Smith, the lead architect from Skidmore, Owings & Merrill (SOM), kept pushing the height. The original plan was for a 700-meter tower, but Smith felt the design looked "stumpy" at that height. He wanted it more slender, more elegant. That elegance required an extra 100+ meters of height, which meant more steel, more concrete, and a much larger bill.

Why the price tag jumped

By the time the dust settled, the cost had ballooned by nearly 70%. Here is why the budget went out the window:

- Material Spikes: Between 2004 and 2008, the global economy was on a tear. The price of iron jumped by about 75% in a single year.

- Design Tweaks: Adding 100 meters to a skyscraper isn't like adding an extra room to a house. It changes the entire structural integrity, requiring more sophisticated wind testing and heavier foundations.

- The Armani Factor: Emaar decided they didn't just want a tall building; they wanted the best building. They brought in Giorgio Armani to design the hotel and residential interiors, which added a massive premium to the finishing costs.

Who Actually Paid for the Burj Khalifa?

This is where the history gets a bit dramatic. Construction started in 2004, and for a few years, everything was great. Money was flowing. Then 2008 hit.

The global financial crisis didn't just "affect" Dubai; it nearly leveled it. Real estate prices crashed. Emaar Properties was suddenly staring at a massive project they couldn't finish. The tower was originally called Burj Dubai, but as the money ran dry, they needed a bailout.

Enter Sheikh Khalifa bin Zayed Al Nahyan, the then-President of the UAE and Ruler of Abu Dhabi.

✨ Don't miss: GDP United States Graph Explained: Why the Line is Moving This Way in 2026

Abu Dhabi stepped in with a massive $10 billion loan to help Dubai cover its debts. As a "thank you" (and a very clear sign of who held the purse strings), the building was renamed Burj Khalifa literally minutes before its grand opening in 2010.

Breaking Down the $1.5 Billion Receipt

If you were to itemize the bill for the world's tallest building, it wouldn't look like your standard home renovation invoice.

The Foundation and Concrete

The tower sits on a 3.7-meter thick concrete mat, which itself sits on 192 piles. They used 330,000 cubic meters of concrete in total. To put that in perspective, that’s about the weight of 100,000 elephants.

Because Dubai is a furnace, they couldn't just pour concrete during the day. It would set too fast and crack. Instead, they mixed the concrete with ice and poured it almost exclusively at night during the summer months. That "ice bill" alone is a line item most developers never have to think about.

The Exterior Skin

The building is covered in 24,348 glass panels. These aren't just windows; they are high-performance pieces of engineering designed to reflect the brutal Arabian sun. The cost of the aluminum used in the facade is equivalent to the weight of five Airbus A380 aircraft.

The Labor Force

At the height of construction, there were 12,000 workers on-site every single day. This is one of the more controversial aspects of the project’s cost. While the $1.5 billion covers the labor, many human rights organizations have pointed out that the actual "cost" was borne by the workers from South Asia who worked in extreme heat for relatively low wages.

Is the Burj Khalifa Actually Profitable?

You’d think a $1.5 billion building would take decades to pay off. In reality, the Burj Khalifa was a financial masterstroke for Emaar.

Almost 90% of the 900 apartments in the tower were sold out within hours of being released to the market back in 2004. They essentially crowdsourced the construction costs from private investors before the building was even halfway done.

Today, the building makes money through:

- Ticket Sales: The "At the Top" observation decks pull in an estimated $600 million+ annually.

- Corporate Suites: High-profile companies pay a massive premium to have an address on the 100th+ floor.

- The Armani Hotel: One of the most expensive stay experiences in the Middle East.

- Service Fees: If you own an apartment there, you're paying tens of thousands of dollars a year just in maintenance.

The "Hidden" Costs of Staying Tall

The $1.5 billion was just the "build" cost. Running this place is an ongoing financial beast.

Take the windows, for example. It takes a crew of 36 people about three to four months to clean the entire exterior. By the time they finish the last window, the first one is already dusty again. They have to use specialized $8 million machines just to access the angles of the spire.

Then there’s the cooling. The air conditioning system is basically equivalent to 13,000 short tons of melting ice every day. The water system pushes nearly 1 million liters of water through 100 kilometers of pipes daily. None of that is cheap.

📖 Related: The Truth About John Barth’s Diamond Riches Formula: Financial Strategy or Marketing Myth?

What You Should Take Away

If you're planning a massive project—or just curious about how the world's elite build their monuments—the Burj Khalifa is the ultimate case study in "Scope Creep."

- Height is Exponential: Going from 700 meters to 828 meters didn't just add 18% to the height; it nearly doubled the complexity and risk.

- Brand Identity Matters: The building would likely be worth less today if it hadn't pushed for that world-record status. The "tallest" label is a marketing engine that pays for itself.

- Liquidity is King: Without the Abu Dhabi bailout, the Burj Khalifa might have sat as an unfinished concrete skeleton for a decade.

For those looking to dive deeper into the economics of supertall structures, the next logical step is looking at the Jeddah Tower in Saudi Arabia. It was designed by the same architect, Adrian Smith, with the goal of hitting the 1,000-meter mark, but it has faced even more dramatic financial hurdles than its Dubai predecessor. Comparing the two reveals just how much of a "perfect storm" of timing and luck the Burj Khalifa actually had.