You step on the gas. The car goes. Most of us don't think twice about the violent mechanical ballet happening three feet under our floorboards, but the modern automatic transmission is easily one of the most complex pieces of machinery in your daily life. It’s a mess of oil, spinning steel, and logic gates. Honestly, it’s a miracle they don't explode more often.

If you've ever wondered how does automatic transmission work without stalling your engine at a red light, you’re looking at a solution to a problem that stumped early engineers for decades. In a manual car, you are the brain. You feel the engine strain, you press the clutch to disconnect the power, and you move a lever. In an automatic, a "hydraulic brain" or a computer chip does that heavy lifting for you. It’s about managing torque. Without that management, your engine would either stall out immediately or scream at 7,000 RPM until it melted into a puddle of aluminum.

The Torque Converter: The Fluid Connection

The biggest difference between a manual and an automatic is how the engine connects to the wheels. There is no solid connection. Instead, there's a big, donut-shaped thing called a torque converter. Imagine two desk fans facing each other. If you turn one on, the air it blows will eventually start spinning the blades of the other fan.

That is basically it.

📖 Related: Machines of Loving Grace: Why Everyone Is Obsessed With Brautigan’s Techno-Utopia Right Now

Except instead of air, the torque converter uses transmission fluid. The "pump" is bolted to the engine, spinning at whatever speed your motor is running. The "turbine" is on the other side, connected to the transmission. As the pump spins, it flings oil against the turbine blades. At a stoplight, the oil is moving slowly enough that the turbine doesn't turn, which is why your car stays still while idling. When you hit the gas, the oil moves with enough force to shove the turbine, and suddenly you're moving.

There’s a middle part called the stator. It’s the secret sauce. It redirects the fluid returning from the turbine so it hits the pump in the direction of rotation, multiplying the torque. It’s a literal force multiplier. This is why automatics feel so smooth when pulling away from a stop—the fluid acts as a cushion.

Planetary Gears: The Rubik's Cube of Steel

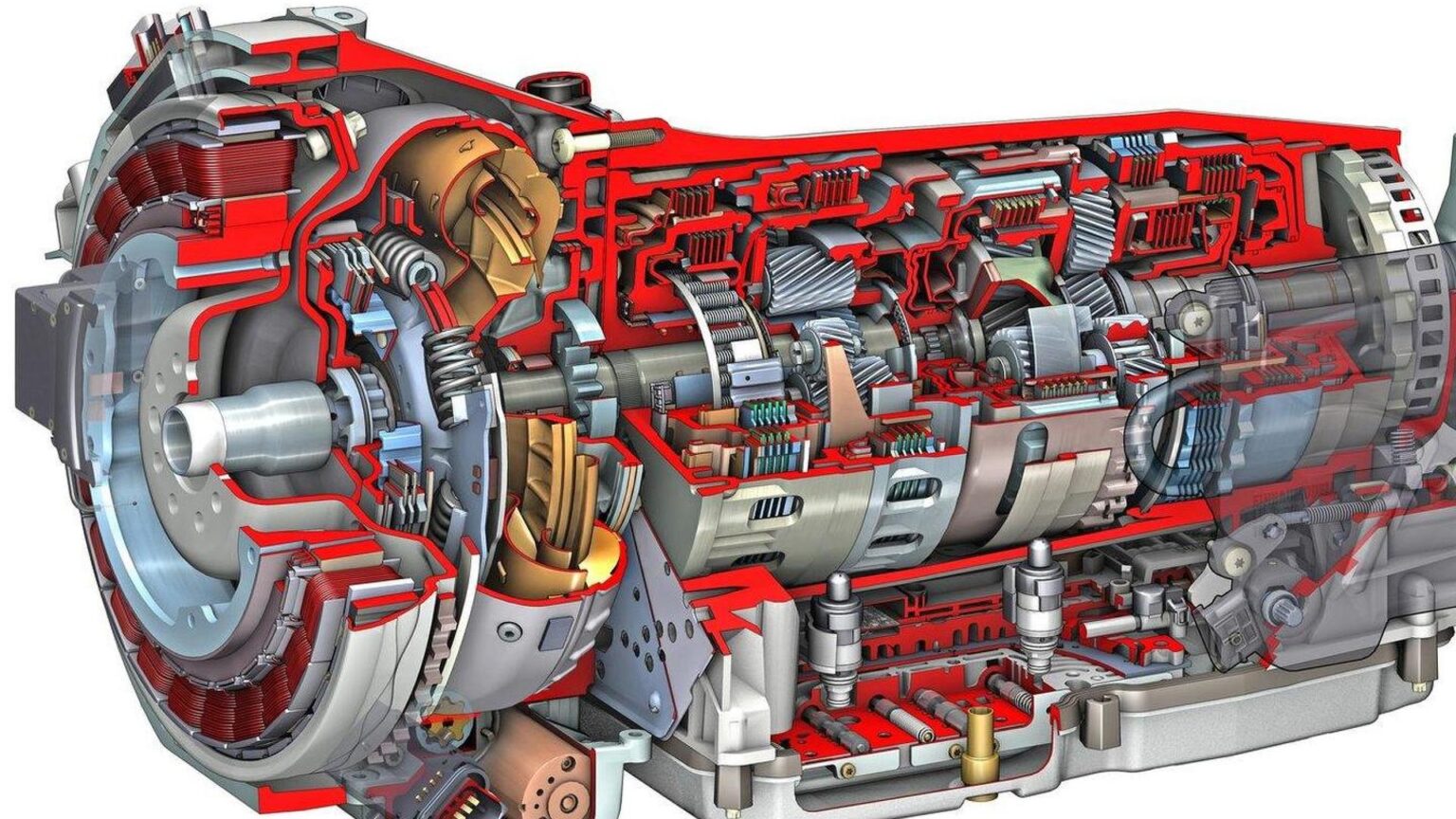

Once that power gets past the torque converter, it hits the gearset. But it’s not just a row of gears like a bicycle. Most automatics use Planetary Gear Sets.

Picture the solar system. You have a central "sun" gear. Around it are "planet" gears held together by a "carrier." Surrounding everything is a big "ring" gear with teeth on the inside. This setup is genius because you can get different gear ratios without ever actually moving gears in and out of mesh. You just lock different parts of the set.

- If you lock the ring gear and turn the sun gear, the planets walk around the ring, giving you a massive power boost (low gear).

- If you lock two parts together, the whole thing spins as one unit (1:1 ratio).

- If you hold the planet carrier still and spin the sun, the ring spins backward. Boom. Reverse.

It’s all about which part is held still and which part is spinning. To do this holding, the transmission uses a series of wet clutches and brake bands. These are small, friction-material discs soaked in oil. When the car decides it's time to shift, hydraulic pressure squeezes these discs together, stopping one part of the planetary set and releasing another. It happens in milliseconds.

The Valve Body: The Hydraulic Brain

Before computers took over in the late 80s and 90s, transmissions were purely "thinking" with hydraulics. This happens in the valve body. If you ever see one, it looks like a literal maze or a "brain" made of cast aluminum channels.

Transmission fluid flows through these channels. As you drive faster, a "governor" (a spinning weight) increases fluid pressure. At the same time, a cable connected to your throttle tells the valve body how hard you're pushing the pedal. The "brain" balances these two pressures. When the speed pressure overcomes the throttle pressure, a valve slides over, diverts oil to a specific clutch pack, and the car shifts.

👉 See also: The Truth About Choosing a Keyboard with Cover for iPad: Why Most People Overpay

It's an analog computer. It’s incredibly elegant and frustratingly difficult to repair if a single grain of dirt gets inside one of those tiny channels.

Modern Electronics and the TCM

Today, your car uses a Transmission Control Module (TCM). It’s not just looking at speed anymore. It’s looking at your altitude, the engine temperature, how aggressively you're steering, and even if you're driving uphill.

According to experts at companies like ZF (who make the 8-speed transmissions found in everything from BMWs to Ram trucks), modern software can predict shifts before you even think about them. They use "fuzzy logic." If the car senses you're driving spiritedly on a winding road, the TCM will hold a lower gear longer to keep the power ready. If you're cruising on the highway, it’ll hunt for the highest gear possible to save fuel.

Why Do We Have So Many Gears Now?

You might remember when 4-speed automatics were the standard. Now, 8, 9, or even 10-speed transmissions are common. Why the overkill?

Efficiency.

Engines have a "sweet spot" (the power band) where they are most efficient. More gears mean the engine can stay in that narrow window regardless of whether you're going 15 mph or 75 mph. It’s also about the "spread." A 10-speed allows for a very short first gear (great for towing) and a very tall top gear (great for quiet, fuel-efficient highway cruising).

When Things Go Wrong: Common Failure Points

Understanding how does automatic transmission work also means understanding how it breaks. Heat is the number one killer. Transmission fluid isn't just a lubricant; it’s a hydraulic fluid and a coolant. When it gets too hot—usually from heavy towing or stop-and-go traffic in summer—it breaks down.

- Slipping: This is usually when those friction clutches mentioned earlier are worn out. The engine revs, but the car doesn't speed up. The "grip" is gone.

- Rough Shifts: This often points to a solenoid issue. Solenoids are electronic "gates" that open and close to let fluid into the valve body. If they get gunked up or the electrical coil fails, the shift will feel like you've been rear-ended.

- Delayed Engagement: You put it in Drive, wait two seconds, and then clunk. Usually, this is low fluid pressure or a seal that’s hardened over time, letting fluid leak past where it should be holding pressure.

The Alternative: CVTs and Dual-Clutches

We should probably mention that not every "automatic" is the same.

💡 You might also like: Mach 11 Speed: What Most People Get Wrong

The CVT (Continuously Variable Transmission) doesn't have gears at all. It uses two pulleys and a steel belt. The pulleys change their width to change the gear ratio. It's like a mountain bike with infinite gears. They’re great for gas mileage but can feel a bit rubbery or "drone" when you're accelerating.

Then there’s the DCT (Dual-Clutch Transmission). This is basically two manual transmissions stuffed into one box. One clutch handles the odd gears (1, 3, 5) and the other handles the even ones (2, 4, 6). While you're in 2nd, the car has 3rd gear already selected and waiting. It just swaps clutches. It's lightning-fast—faster than any human could ever shift.

Actionable Maintenance for Longevity

If you want your transmission to last 200,000 miles, stop believing "lifetime fluid" claims. Most mechanics, including the folks over at Car Wizard or Engineering Explained, will tell you that fluid should be changed.

- Check your fluid: If your car has a dipstick (many modern ones don't), the fluid should be bright red and smell slightly sweet. If it’s dark brown or smells like burnt toast, you’re in trouble.

- Service intervals: Every 40,000 to 60,000 miles is a safe bet for a fluid and filter change, regardless of what the manual says about "lifetime" use.

- Cooling: If you tow regularly, install an external transmission cooler. It’s a small radiator that can double the life of your gearbox.

- Stop completely: Don't flip from Reverse to Drive while the car is still rolling. It forces the clutches to stop the entire momentum of the vehicle, which causes massive heat spikes and wear.

The automatic transmission is a masterpiece of mechanical logic. It manages thousands of pounds of force with nothing but some clever gears and a bath of oil. Treat it well, and it'll keep that power moving.