So, you’ve seen the viral TikToks. You know the ones—a massive flat-bed truck pulls up, drops off a few shrink-wrapped pallets, and suddenly someone has a guest house or a backyard studio for what looks like pocket change. People are obsessed with house kits from Home Depot right now because, let’s be honest, the housing market is a nightmare. Buying a pre-cut, ready-to-assemble structure feels like a cheat code for homeownership. But is it?

It’s complicated.

Building a house from a box isn't just "IKEA but bigger." When you start browsing the Home Depot website for these kits, you’ll see brands like Plus 1 Homes or Arched Cabins popping up. They look beautiful in the renders. You see steel frames, sleek rooflines, and descriptions that promise "easy assembly." But here’s the thing: most of these are just the "bones." You’re buying a skeleton. You aren't buying a finished home with a kitchen, plumbing, or even a floor in some cases.

The Reality of the Steel Frame Craze

Most of the popular house kits from Home Depot are made by a company called Plus 1 Home Kits. They specialize in cold-formed steel frames. Steel is great. It doesn't rot, termites hate it, and it won't warp like the cheap lumber you find at your local yard. Plus, these frames are often pre-drilled for electrical and plumbing. That's a huge win for DIYers who don't want to spend three days measuring where a wire should go.

But wait.

When you drop $40,000 on a 700-square-foot "Getaway" kit, you need to look at the "What's Included" tab very closely. You are getting the steel studs. You are getting the track. You are getting the hardware to bolt it together. You are not getting the foundation. You are not getting the windows (usually). You definitely aren't getting the drywall, the insulation, the HVAC system, or the toilet.

Honestly, the "house kit" is really a "structural kit." You still have to play general contractor. If you don't know how to pour a concrete slab or hire an excavator, that $40,000 kit is going to sit in your driveway and rust. It's a massive undertaking that most people underestimate because the price tag on the website looks so approachable.

Why the "Getaway" Model Became a Legend

The "Getaway" is probably the most famous kit they sell. It’s roughly 540 square feet, designed to sit over a garage or stand alone as a small ADU (Accessory Dwelling Unit). People love it because it’s a steel-frame structure that can be assembled in a few days by a small crew. Steel is lighter than wood. You can literally carry the wall sections with two people.

But here is the catch that most people miss: permits.

Just because Home Depot sells it doesn't mean your city will let you build it. Many zoning boards look at these kits and treat them like "manufactured homes" or "tiny houses," which can be a legal nightmare in strict residential zones. Before you even think about clicking "Add to Cart," you need to walk into your local building department with the PDF of the engineering plans. If they won't sign off on the wind load or snow load ratings for your specific county, that kit is basically an expensive garden ornament.

Breaking Down the Actual Cost

Let’s talk numbers. This is where the dream usually hits a wall.

Say you buy a mid-sized house kit from Home Depot for $35,000. That’s just the start. Experts in the prefab industry, like those at Dwell or various modular home consultants, typically suggest the "Rule of Three." Whatever you pay for the shell, expect to pay three times that amount to finish the home.

- The Foundation: You can’t just put a steel frame on the grass. A concrete slab for a 500-square-foot structure can cost anywhere from $5,000 to $10,000 depending on your soil and local labor rates.

- Utilities: Running a sewer line, water line, and electrical trench from your main house to the ADU? That’s easily $3,000 to $8,000. If you’re building on raw land, a septic system and a well will cost you $20,000 or more.

- Finishing: Windows, doors, roofing, siding, insulation, drywall, flooring, cabinets... it adds up. Even if you go cheap and buy everything else at Home Depot too, you're looking at another $30,000 in materials alone.

So, your $35,000 "house" is now a $110,000 project. Still cheaper than a traditional build? Usually, yes. But it's not the "budget" miracle people think it is.

The DIY vs. Pro Debate

Can you build this yourself? Maybe.

If you can read a blueprint and know how to use an impact driver, you can probably put the frame together. The steel pieces are numbered. It’s like a giant Erector set. However, once that frame is up, you’re dealing with "real" construction. Hanging 4x8 sheets of drywall is heavy, miserable work. Wiring a sub-panel can kill you if you mess it up.

Most people who succeed with house kits from Home Depot use a hybrid approach. They assemble the frame themselves to save on labor, then hire a licensed plumber and electrician to do the "rough-in" work. This keeps the build legal and safe while still shaving a few thousand dollars off the total bill.

The Problem With Financing

Traditional mortgages do not like house kits.

Banks want to see a finished product or a contract with a licensed general contractor. If you tell a loan officer you want $50,000 to buy a steel frame kit from a hardware store, they’re going to laugh you out of the office. Most people buy these kits using:

- Cash savings.

- A Home Equity Line of Credit (HELOC) on their primary residence.

- Personal loans (which have high interest rates).

This is a major barrier. These kits are marketed as a solution for people who can’t afford a traditional home, but the people who can actually afford to build them usually have a lot of liquid cash or equity already. It's a bit of a Catch-22.

Don't Ignore the "Tiny" Options

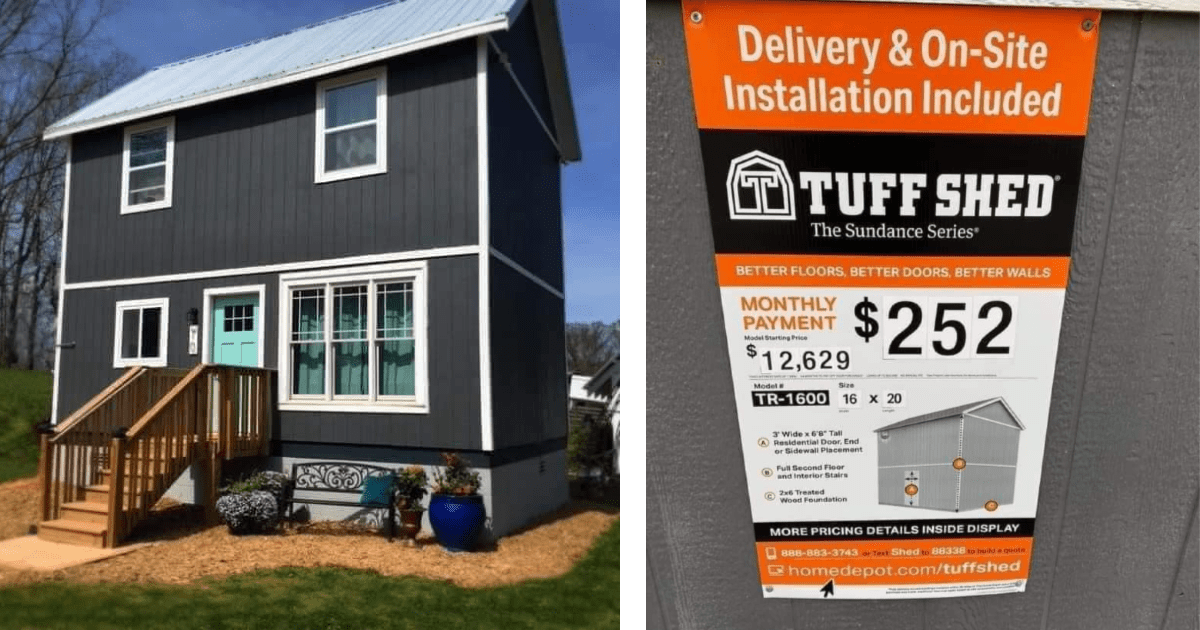

Not all house kits from Home Depot are 1,000-square-foot residences. Some are essentially high-end sheds that people convert. The Tuff Shed "Pro Tall Ranch" is a common choice. While technically sold as a storage shed, people have been "shed-to-house" converting these for years.

The advantage here is that Tuff Shed often includes installation. They show up, build the shell in a day, and leave. You’re left with a wood-framed, weather-tight box. It’s much easier to finish a wood-framed shed than a steel-frame kit because every contractor knows how to work with 2x4s. Steel requires special self-tapping screws and different electrical boxes, which can confuse a rookie.

Logistics: The Part Nobody Records for Instagram

When you order one of these, a semi-truck is going to show up. If you live on a narrow cul-de-sac or a dirt road with low-hanging branches, that truck isn't getting to your house. You'll have to meet them at a parking lot and ferry the pallets back and forth on a smaller trailer.

Also, you need a way to offload. We’re talking thousands of pounds of steel. You might need to rent a forklift or a skid steer for the day. This is another "hidden" cost that people forget. You aren't just carrying these boxes into your garage one by one.

Sustainability and Longevity

One thing that really works in favor of these kits is their durability. Steel doesn't off-gas like some treated lumbers, and it's 100% recyclable. If you live in an area prone to wildfires or hurricanes, a steel-framed kit is actually a very smart choice. Once it's bolted to a foundation and sheathed properly, it's incredibly strong.

But you have to watch out for "thermal bridging." Steel is a great conductor of heat. If you don't insulate it correctly—meaning you need a thermal break between the steel and your siding—your house will be an oven in the summer and a freezer in the winter. Most people use spray foam or rigid foam board for this. It’s more expensive than fiberglass batts, but it’s the only way to make a steel kit truly livable.

Actionable Steps Before You Buy

Don't just look at the pictures. If you're seriously considering one of these kits, you need to do the boring legwork first.

- Check your "Minimum Square Footage" laws. Many towns have laws stating a permanent residence must be at least 800 or 1,000 square feet. If your kit is 500, you might never get a certificate of occupancy.

- Get a quote for a foundation first. Call a local concrete company. Tell them the dimensions. You might be shocked to find out the slab costs half as much as the house.

- Download the assembly manual. Most of these are available on the Home Depot product page under "Additional Resources." Read it front to back. If the terms "anchor bolts," "self-tapping fasteners," or "squareness tolerance" scare you, don't do this alone.

- Look into "Owner-Builder" insurance. Your standard homeowner's policy won't cover a pile of steel sitting in your yard, and if a friend helps you and gets hurt, you’re liable.

Building a kit home is a valid way to beat the housing market, but it’s a job, not a hobby. It requires a massive amount of coordination. If you go into it knowing that the "kit" is only 30% of the total work, you’ll actually stand a chance of finishing it. Just don't expect it to be easy because a website told you it was.