You’ve been there. You spend four hours leaning over a walnut tabletop, your back is screaming, and the second you wipe it down with mineral spirits, you see them. Swirls. Pigtails. Little curly-cue scratches that look like a caffeinated toddler took a needle to your wood. It’s infuriating. Most people blame their sander or their "cheap" wood, but honestly, the culprit is usually sitting right in the palm of your hand. It’s the disc. Specifically, how you’re using hook loop sanding discs and the massive misconceptions surrounding them.

Sanding is boring. We all hate it. But if you treat your abrasive like a throwaway commodity rather than a precision tool, you’re basically sabotaging your project before the finish even touches the surface.

The Hook and Loop Lie

We call it Velcro, but it’s not. Well, legally it’s not Velcro® brand, but the mechanic is the same. You have a backing pad with tiny plastic hooks and a sanding disc with a fuzzy fabric backing. It’s convenient. It’s fast. But that convenience comes with a hidden cost that most DIYers and even some "pros" completely ignore: the cushion effect.

Unlike PSA (Pressure Sensitive Adhesive) discs that stick flat and hard to a backing pad, hook loop sanding discs sit on a microscopic bed of air and plastic loops. This creates a tiny bit of "give." If you press down too hard—which everyone does when they’re tired—the hooks compress unevenly. This tilts the grit. Instead of the abrasive particles shearing off the wood fibers cleanly, they dig in at an angle. That’s where your pigtails come from. It’s not a mystery; it’s physics.

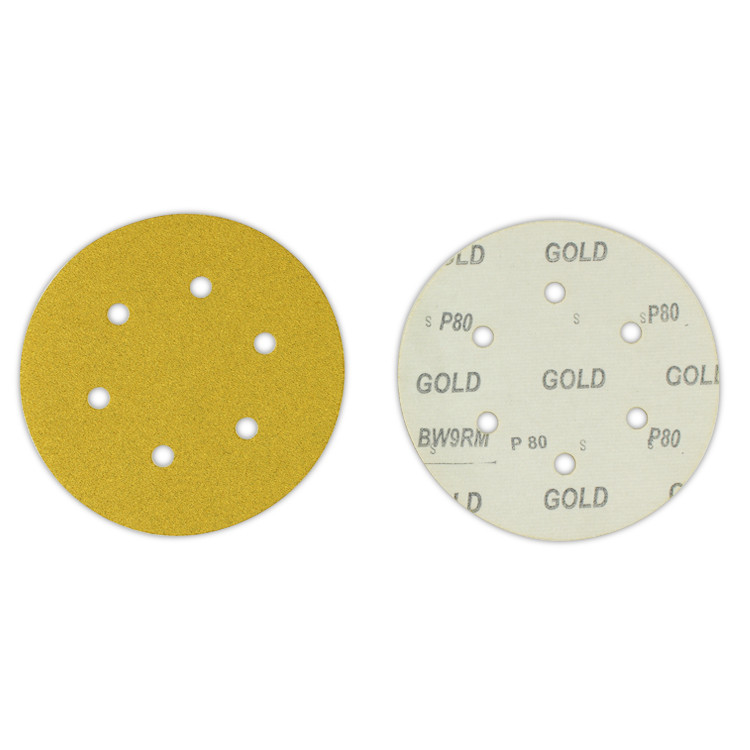

Why 5-Hole, 8-Hole, and Mesh Actually Matter

Ever noticed how some discs have eight holes, some have five, and some look like a window screen? That’s not just for aesthetics. Dust is the enemy of a good finish. If you’re using an 8-hole sander with 5-hole hook loop sanding discs, you’re essentially sanding with a pile of rocks.

The dust has nowhere to go. It gets trapped between the disc and the wood, forming "pills." These little balls of sawdust and resin are harder than the wood itself. They roll around under your sander like ball bearings, carving those deep, nasty scratches into your work.

- Standard Punched Holes: Cheap, effective, but they require perfect alignment. If you’re off by a millimeter, your dust collection is useless.

- Mesh Discs (like 3M Cubitron II or Mirka Autonet): These are a total game-changer. Since the whole disc is porous, you don't have to line up holes. More importantly, the dust extraction is nearly 90% better.

- The "Universal" Pattern: Some brands like Bosch or Diablo use a multi-hole pattern designed to fit anything. They’re fine, but they often sacrifice surface area for compatibility.

Honestly, if you’re still using the cheap 50-pack discs from the big-box store, you’re working twice as hard as you need to. High-end ceramic abrasives stay sharp. They don't just "rub" the wood; they cut it.

The Science of Ceramic vs. Aluminum Oxide

Most people just look at the grit number. 80 is coarse, 220 is fine. Easy, right? Not really. The material of the grit on your hook loop sanding discs determines how long you can sand before you start burning the wood.

Aluminum Oxide is the old-school standard. It’s brown or white, cheap, and it gets dull fast. When it gets dull, it generates heat. Heat causes the resin in the wood (especially in pine or cherry) to gum up the disc. Once a disc is "loaded" with resin, it’s dead. You can try those rubber cleaning sticks, but usually, you’re just wasting time.

Then there’s Ceramic and Zirconia. These are usually blue, purple, or red. They are "friable." This means that as you use them, the grains actually fracture into new, sharp edges. They stay sharp until the grit is literally gone. Brands like 3M have mastered this with their "Precision Shaped Grain" technology. Instead of crushed rocks, they use tiny ceramic triangles that slice through wood fibers like a plow through a field. It sounds like marketing fluff until you use one and realize you finished an entire dining table with two discs instead of ten.

Stop Skipping Grits

This is the most common mistake in the shop. You start at 80 because the wood is rough. You’re in a hurry, so you jump straight to 150, then 220.

Don't do that.

The purpose of each consecutive grit is to remove the scratches left by the previous grit. An 80-grit disc leaves deep valleys. A 150-grit disc isn't "strong" enough to reach the bottom of those 80-grit valleys. You’ll end up with a surface that feels smooth to your hand but looks like a topographical map once you apply a dark stain or a glossy wipe-on poly.

The rule of thumb: never skip more than one grit level. The sequence should be 80, 100, 120, 150, 180, 220. If the wood is already fairly surfaced, you can start at 100 or 120. But jumping from 80 to 220 is a recipe for a "botched" finish.

The Pad Problem Nobody Talks About

We talk about the discs, but what about the thing the disc sticks to? The backing pad on your orbital sander is a wear item. Over time, those tiny plastic hooks get melted or crushed. If your hook loop sanding discs are flying off the sander like a frisbee, it’s not the disc’s fault—it’s your pad.

Heat is the killer here. If you use too much pressure or too high a speed on a hard wood like Ipe or White Oak, the friction generates enough heat to melt the hooks. Once they melt, they won't grab the fuzz on the back of the disc.

Pro Tip: Use an "interface pad." This is a thin, foam-backed layer that sits between your sander and the disc. It protects your expensive backing pad from heat and allows the disc to contour to curved surfaces. It’s a $10 investment that saves you $30 on a replacement backing pad.

Practical Steps for a Flawless Finish

If you want to stop hating your sander, change your workflow. It’s about discipline, not muscle.

💡 You might also like: Free LPN NCLEX Practice Test: Why Most Nursing Students Fail to Use Them Correctly

- Vacuum everything. Not just the wood. Vacuum the disc. Vacuum the sander. If a single grain of 80-grit sand falls off and gets under your 220-grit disc, it will act like a boulder and ruin your surface.

- Slow down your hand, not the motor. Move the sander at a rate of about one inch per second. It feels agonizingly slow. Do it anyway.

- The Pencil Trick. Lightly scribble pencil marks across the entire surface of your project. Sand until the marks are gone. This is the only way to ensure you’ve actually sanded the entire area evenly.

- Check your light. Turn off the overhead lights and hold a flashlight at a low angle across the wood. This "raking light" will reveal every scratch and pigtail that your eyes missed.

- Let the tool work. Use the weight of your hand only. If you’re pushing down, you’re creating heat and uneven wear.

The Real Cost of Cheap Discs

You can buy a pack of 100 hook loop sanding discs on Amazon for $15. They’re tempting. But if you value your time, they are a massive rip-off. They clog in minutes, the hooks tear off the backing, and the grit size is inconsistent—meaning a "120 grit" disc might have stray 60-grit particles that scratch your work.

Spend the extra money on premium abrasives. Look for "stearated" coatings, which are basically a dry lubricant that prevents clogging. Brands like Festool, 3M, and Mirka are the industry leaders for a reason. They don't just make things smooth; they make the process predictable.

Sanding will never be fun. It’s dusty, loud, and vibrating. But when you use the right disc and respect the mechanics of how that disc interacts with the wood, you stop fighting the material. The goal isn't just to get to the finish—it's to make sure the finish is worth the effort you put in.

Next time you’re at the store, skip the bargain bin. Grab a box of ceramic mesh discs and an interface pad. Your hands (and your tabletop) will thank you.

Actionable Next Steps:

- Check your sander's backing pad: If the hooks look flat or shiny, order a replacement pad today to prevent disc slippage.

- Upgrade to mesh: Buy a small pack of mesh-style abrasives to compare against your current punched-hole discs; notice the difference in dust left on the surface.

- Implement the Pencil Trick: On your next project, use a soft lead pencil to track your progress through each grit to ensure no spots are missed.

- Clean between grits: Use a tack cloth or a vacuum with a brush attachment to remove all loose grit before moving from a coarse disc to a finer one.