You’ve probably heard the rumors or seen the headlines about a Honda new plant in Indiana, but the reality is actually a bit more complex—and a lot more expensive—than just adding a few extra square feet to a warehouse. We aren't just talking about a minor upgrade here. Honda is dropping roughly $1.1 billion into their Greensburg operations. It’s a massive bet on the future of electric vehicles (EVs) in the American heartland.

Greensburg is a quiet spot. If you’ve ever driven through Decatur County, you know the vibe. It’s fields, small-town charm, and a whole lot of Honda logos. For years, the Indiana Auto Plant (IAP) has been the backbone of the local economy, churning out Civics and CR-Vs like clockwork. But things are changing. The world is going electric, and Honda, which was honestly a little late to the EV party compared to Tesla or even Hyundai, is finally sprinting to catch up.

What the Honda New Plant in Indiana Actually Means for Greensburg

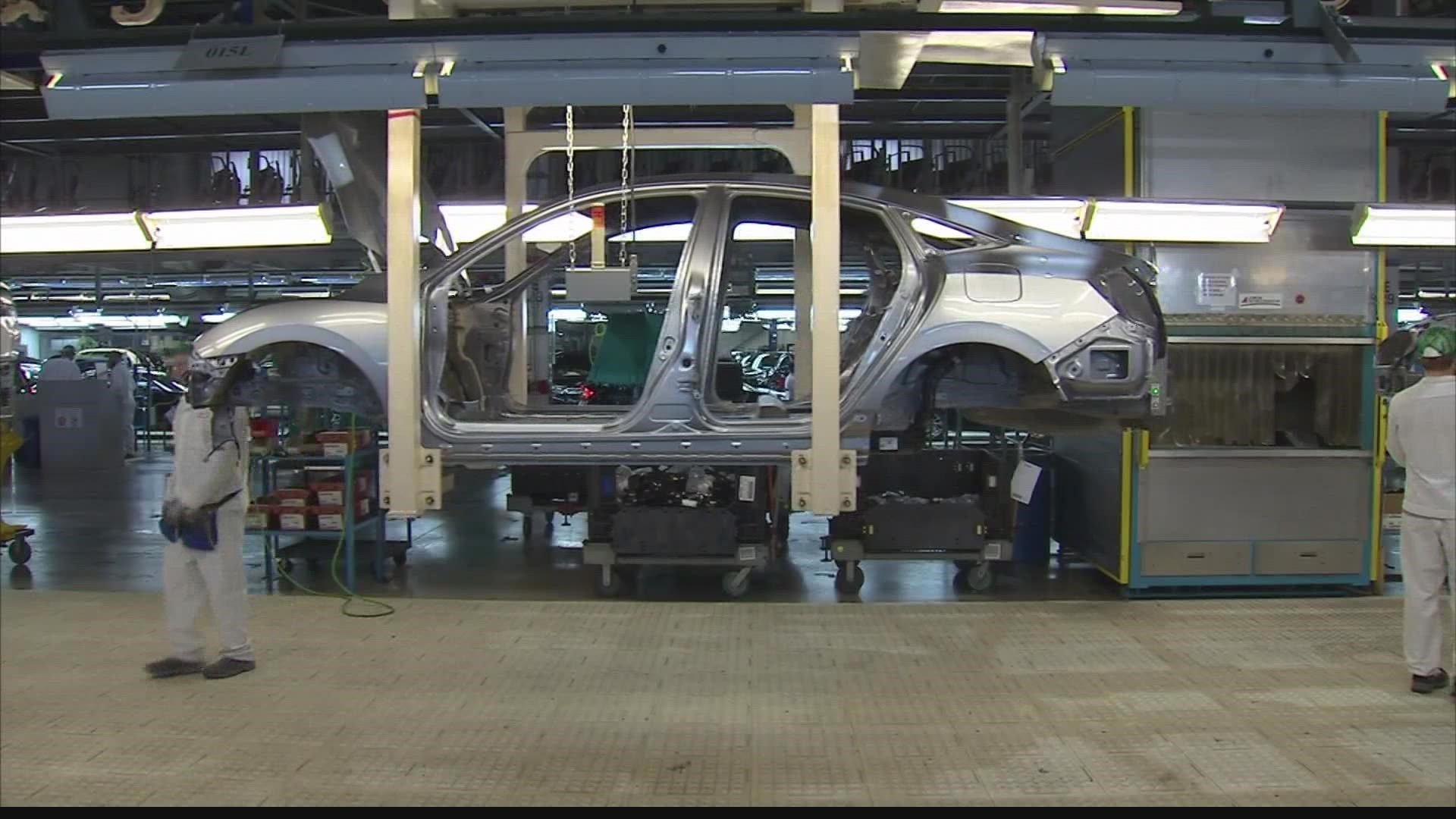

When people talk about a "new plant," they’re often referring to the massive retooling and expansion project currently transforming the existing Greensburg footprint. This isn't just about painting the walls. It’s a fundamental shift in how cars are built. Honda is prepping the site to become a primary hub for their "EV Hub" strategy in the United States.

Basically, they are turning Ohio and Indiana into a massive, interconnected battery and EV production corridor.

Why Indiana? Well, the infrastructure is already there. You have a workforce that knows how to build cars. You have the supply chains. Moving to a brand-new state would be a logistical nightmare. By investing $1.1 billion specifically into the Indiana Auto Plant, Honda is essentially doubling down on the people who are already on the payroll. It’s a relief for the town, honestly. There was a lot of anxiety a few years ago that the shift to electric might leave traditional plants in the dust. Instead, Greensburg is getting a front-row seat.

The scale is hard to wrap your head around. We’re talking about new assembly lines that can handle the heavy battery packs required for EVs. Electric cars are heavy. Really heavy. You can't just throw a 1,500-pound battery onto a line designed for a lightweight internal combustion engine without breaking something. So, the "new" part of the plant involves massive structural reinforcements and high-tech robotics that didn't exist when the plant first opened in 2008.

The $4.4 Billion Connection You Can't Ignore

To understand the Honda new plant in Indiana, you have to look across the border at Ohio. Honda and LG Energy Solution are building a $4.4 billion battery plant in Jeffersonville, Ohio.

This is the "mother ship."

The batteries made in Ohio will be shipped directly to the Indiana plant. It’s a tight loop. By keeping the battery production and the vehicle assembly within a few hours of each other, Honda cuts down on shipping costs and—perhaps more importantly—minimizes the carbon footprint of the manufacturing process itself.

🔗 Read more: USD to UZS Rate Today: What Most People Get Wrong

Why the "Hub" Strategy Matters

- Efficiency: It’s easier to manage quality when your battery supplier is basically a neighbor.

- Speed: Honda wants to start producing EVs in 2025. You can't do that if your batteries are coming from overseas.

- Tax Credits: Let's be real—the Inflation Reduction Act (IRA) changed everything. To get those juicy federal tax credits, the cars and the batteries have to be made in North America.

Honda’s investment in Indiana is a direct response to these economic pressures. They aren't just doing it because they like the scenery; they're doing it because it’s the only way to stay competitive in a market where a $7,500 tax credit can make or break a sale.

The Human Element: Jobs and the "EV Skills Gap"

One thing most people get wrong is thinking that more robots mean fewer humans. While the Honda new plant in Indiana will be incredibly automated, the headcount isn't exactly shrinking. It’s evolving.

I’ve talked to folks in the industry who say the biggest challenge isn't the technology—it’s the training. Building an EV is different. You're working with high-voltage systems. One mistake and, well, things get dangerous very quickly. Honda is investing heavily in "upskilling" their current workforce.

They are teaching people who have spent twenty years working on exhaust systems how to handle lithium-ion modules. It’s a massive undertaking. The company has even partnered with local community colleges to ensure a steady stream of technicians who understand power electronics and software-defined vehicle architecture.

"The transition to EVs is as much a human transition as it is a mechanical one," says one industry analyst.

If you live in Indiana, this is great news. It means the jobs are staying put, but the type of work is getting more sophisticated. It’s not just "bolting parts together" anymore. It’s managing complex systems.

Addressing the Skepticism: Is the Market Ready?

Now, we have to talk about the elephant in the room. EV sales have slowed down a bit recently. Some people are looking at Honda's billion-dollar investment and wondering if they're nuts.

But here’s the thing: Honda plays the long game. They aren't looking at next quarter’s sales. They’re looking at 2030 and 2040. By then, the transition won't be a choice; it'll be the standard. By building the Honda new plant in Indiana infrastructure now, they are avoiding the panic that will hit other automakers who waited too long to pivot.

💡 You might also like: PDI Stock Price Today: What Most People Get Wrong About This 14% Yield

The Hybrid Bridge

Honda is also being smart by not going 100% electric overnight. The Indiana plant is incredibly flexible. Currently, it produces the CR-V Hybrid, which is selling like crazy. This "hybrid bridge" allows them to keep the lights on and the profits flowing while they fine-tune the EV assembly lines.

It's a hedge.

If the EV market stays soft for another two years, they just crank out more hybrids. If EVs explode in popularity, they flip the switch. This flexibility is exactly why the Greensburg facility was chosen for this massive infusion of cash.

What Actually Changes on the Factory Floor?

Walking through a plant during a retooling like this is surreal. You’ll see sections of the floor that look like a sci-fi movie—shining white floors, silent AGVs (Automated Guided Vehicles) gliding around—right next to older sections where things still feel a bit more "industrial."

The Honda new plant in Indiana upgrades include:

- A New Power Hub: Dedicated areas for battery module installation.

- Advanced Casting: Moving toward larger, integrated components to reduce the number of welds.

- Software Integration Stations: Where the car’s "brain" is flashed with the latest firmware.

It’s a cleaner environment, too. EVs don't have oil, gas, or complex transmission fluids in the same way. The assembly line for an EV is, surprisingly, much quieter.

The Environmental Ripple Effect

Honda is aiming for "Triple Zero"—zero carbon emissions from their products, zero carbon from their corporate activities, and 100% sustainable material use.

The Indiana expansion is a huge part of this. They aren't just making "green" cars; they're trying to make them in a "green" way. This includes water recycling programs at the Greensburg plant and efforts to reduce landfill waste to nearly zero.

📖 Related: Getting a Mortgage on a 300k Home Without Overpaying

Some critics argue that the lithium mining required for these batteries negates the environmental benefits. It’s a fair point. Honda is countering this by looking into battery recycling programs that would allow them to reclaim minerals from old batteries and put them right back into the production line in Indiana. It’s a "circular economy" goal that is still in its early stages, but the infrastructure being built now is designed to support it.

Real-World Impact: Small Town, Big Changes

Greensburg has a population of around 13,000 people. When a company like Honda decides to spend a billion dollars in a town that size, every single person feels it.

Real estate prices in Decatur County have been creeping up. New restaurants are opening. The local schools are getting more support through Honda’s various community grants. It’s a symbiotic relationship. Honda needs a stable, happy town to provide their workers, and the town needs Honda to stay relevant in a changing global economy.

There are challenges, of course. Traffic around the plant can be a nightmare during shift changes. And as the plant grows, the demand for housing is outstripping supply. But compared to the alternative—a town drying up because the local factory closed—these are "good" problems to have.

What Most People Get Wrong About This Expansion

A common misconception is that this is a brand-new building on a brand-new plot of land. While there are physical additions, the "new plant" is more about the transformation of capability.

Another mistake? Thinking this is only about the Prologue (Honda’s current EV). The Prologue was actually built in partnership with GM. The Honda new plant in Indiana is about Honda’s own internal EV platform, known as the "Honda e:Architecture." This is the real deal. This is Honda doing it their way, with their own engineering, from the ground up.

Actionable Insights for Hoosiers and Investors

If you’re watching this development closely, there are a few things you should keep in mind:

- For Job Seekers: Don't wait. If you want to work at the updated Indiana plant, start looking at certifications in high-voltage systems or industrial automation. The "manual labor" days aren't gone, but the "technical labor" days are definitely here.

- For Local Businesses: The influx of specialized contractors and engineers during this multi-year retooling phase is a huge opportunity for service-based businesses in the Greensburg area.

- For Car Buyers: Expect the first "all-Honda" EVs to start rolling off lines in the mid-2020s. These will likely be more integrated and "Honda-feeling" than the GM-partnered models we see today.

- For the Curious: Keep an eye on the Ohio battery plant progress. The timeline of the Indiana plant is tethered to Ohio. If the battery plant faces delays, the Indiana EV rollout will likely shift as well.

The Honda new plant in Indiana is a massive signal of confidence in the American manufacturing sector. It proves that the "Rust Belt" can become the "Battery Belt" if the investment is there. Honda isn't leaving; they're digging in. And they're bringing a billion dollars and a high-tech future along for the ride.

Key Takeaways for the Future of Indiana Manufacturing

The transition is happening, whether we're ready or not. The Greensburg facility is no longer just a "satellite" plant; it's becoming a cornerstone of Honda's global strategy.

- Monitor the construction milestones at the Greensburg site through 2025.

- Watch for the announcement of specific new EV models to be assigned to the Indiana lines.

- Check local employment listings for "EV Assembly Technician" roles to see how the job descriptions are shifting in real-time.