If you’ve spent any time on a high-rise construction site or a massive renovation project, you’ve seen them. Those vertical steel monsters holding up thousands of pounds of wet concrete or structural steel. Heavy duty shoring posts aren't just "props." They are the literal backbone of structural safety. But honestly, most crews treat them like an afterthought until something starts creaking.

That creak? It’s the sound of a structural failure waiting to happen.

I’ve seen engineers argue for hours over the exact PSI of a concrete pour, only to have the foreman use whatever beat-up shoring posts were sitting in the back of the yard. It’s a recipe for disaster. When we talk about "heavy duty" in this context, we aren't just talking about a thicker coat of paint. We are talking about load capacities that can exceed 10,000 lbs per post depending on the extension height. If you’re winging it, you’re playing a dangerous game.

The Math Behind the Metal

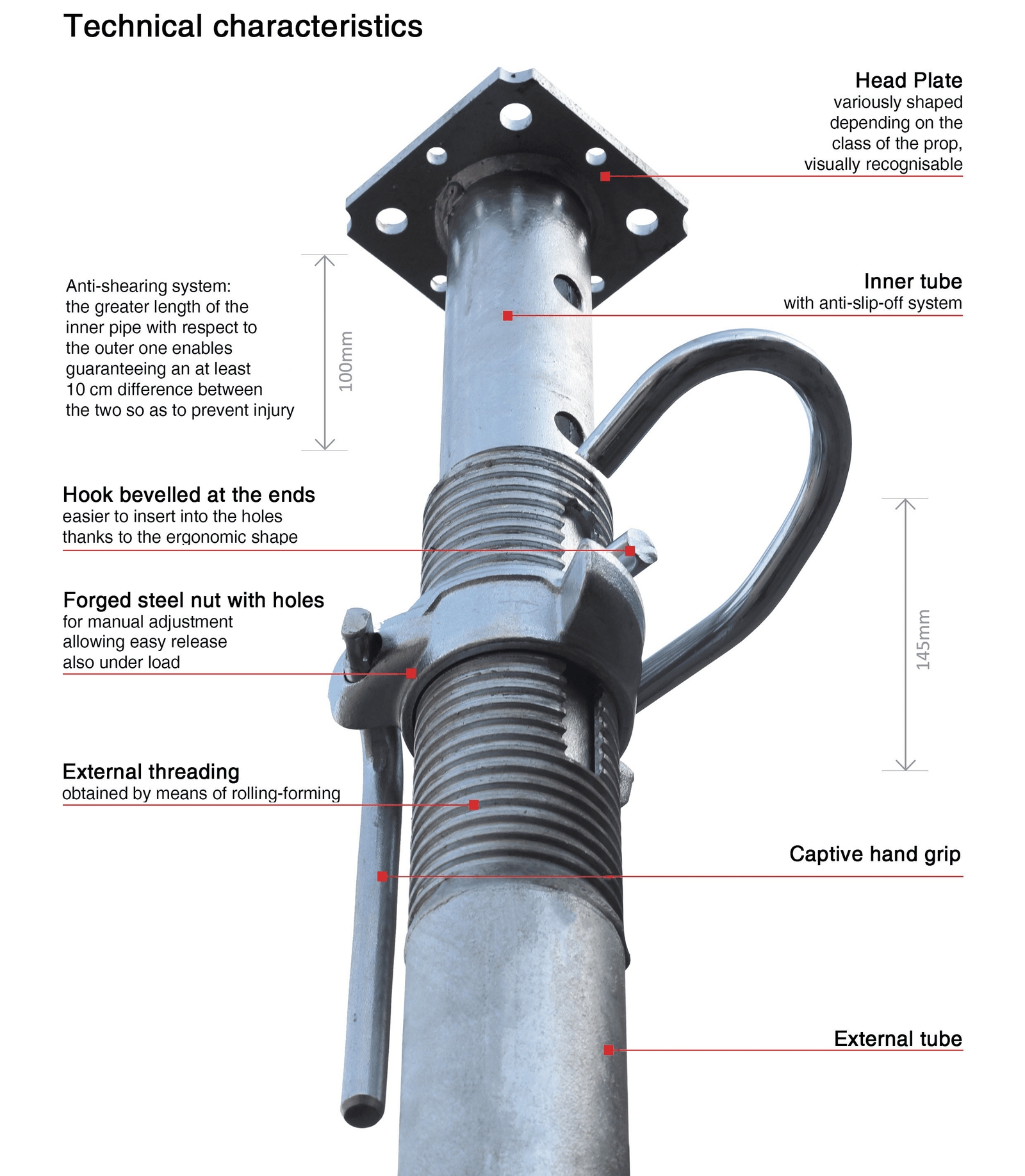

Let’s get real about how these things actually work. A shoring post is basically a telescopic steel tube. You’ve got an inner tube, an outer tube, and a pin that holds them together. Simple, right?

✨ Don't miss: Siemens in the News: What the Massive Nvidia Deal and Healthineers Spin-off Really Mean for You

Not really.

As you extend that inner tube, the physics of the post change completely. A post that can hold 12,000 lbs when it's closed down to 6 feet might only handle 4,000 lbs when it’s fully extended to 11 feet. This is due to something called the slenderness ratio. Basically, the taller and thinner an object is, the more likely it is to buckle sideways under a vertical load.

I once saw a project in Chicago where they underestimated the lateral force of a wind gust on a partially cured slab. Because the heavy duty shoring posts were extended to their max limit without enough X-bracing, the whole system started to "sway." It didn't collapse, but the remedial work cost more than the original pour.

Why Standard Props Just Don't Cut It

Most people confuse standard "Acrow" style props with true heavy duty shoring posts.

Standard props are fine for residential basements or light timber framing. They’re light. You can toss them around. But in commercial infrastructure? They’re basically toothpicks.

True heavy duty posts, like the Doka Eurex series or the Peri PEP Ergo line, use high-strength steel and often feature "drop heads." A drop head is a piece of engineering magic that allows you to strike the formwork (the plywood and beams) while leaving the shoring post in place as a "re-shore." This speeds up construction cycles significantly. You aren't waiting 28 days for full cure strength before moving your gear to the next floor.

- High-yield steel (S235 or higher)

- Hot-dip galvanization for rust prevention (because rust eats capacity)

- Thread cleaners (so you don't need a sledgehammer to adjust the nut)

- Anti-crush features (saving fingers from getting smashed when the inner tube slides down)

The Great Galvanization Debate

Some guys swear by painted posts. They're cheaper. They look "new" for about a week.

But here’s the thing: paint hides cracks. In a high-stakes environment, you want to see the metal. Hot-dip galvanization is the industry standard for a reason. It bonds with the steel. It doesn't just sit on top. If a galvanized heavy duty shoring post is starting to fail or corrode, you’ll see the white rust or the structural pitting immediately.

Furthermore, the friction on the threads of a painted post is a nightmare. Try adjusting a painted nut that’s been sitting in the rain for three months. You’ll spend more on labor hours fighting the equipment than you saved on the initial purchase.

💡 You might also like: Live gold rate at chennai: What Most People Get Wrong

What the Manufacturers Won’t Tell You About Load Charts

Every reputable manufacturer provides a load chart. You’ve probably seen them—a grid of heights versus weights.

But those charts assume a perfect world. They assume the ground is perfectly level. They assume the load is perfectly centered (concentric loading). They assume no one is bumping into the posts with a skid steer.

In reality, eccentric loading is the silent killer. If your beam isn't centered perfectly on the top plate of the post, the load is "off-center." This creates a bending moment. A post rated for 8,000 lbs might fail at 5,000 lbs if the load is just two inches off-center.

I remember a bridge project where the contractor used heavy duty shoring posts but didn't account for the slope of the soffit. The load pushed the posts at an angle. If it weren't for a very observant safety inspector who noticed the base plates "walking," that bridge section would have ended up in the creek.

Maintenance: The Most Ignored Safety Step

You can't just buy these and forget them.

Inspect the pins. The pin is the most critical point of failure. If someone replaces a high-tensile steel pin with a piece of rebar or a Grade 2 bolt they found in the truck, the load rating of that heavy duty shoring post is now exactly zero. It's a death trap.

Check the "plumb." A post that is out of plumb by even 1 or 2 degrees loses a massive chunk of its capacity. Use a spirit level. Use a laser. Don't eyeball it. Your eyes lie; gravity doesn't.

Practical Next Steps for Your Site

If you're responsible for procurement or safety on a site using shoring, stop looking at the price tag first. Start with the engineering requirements.

- Audit Your Inventory: Get rid of any posts with visible bends, severely rusted threads, or makeshift pins. If it looks "kinda" sketchy, it is sketchy.

- Verify the Load Charts: Don't just trust the "Heavy Duty" label. Get the specific data sheet for the brand and model you are using. Make sure your extension heights match the capacity needed for the thickness of the concrete you're pouring.

- Check Your Base Plates: Ensure the ground (or the floor below) can actually handle the concentrated point load. A heavy duty post is useless if it just punches a hole through the mud or a thin slab. Use "mudsills" (usually 2x10 or 2x12 lumber) to spread that weight out.

- Bracing is Non-Negotiable: For heights over 10 feet, you almost always need lateral bracing. Use scaffolding tubes and right-angle couplers to tie the posts together. This turns individual sticks into a rigid "tower" system.

- Train the Crew: Most accidents happen because a worker "adjusted" a post without realizing it was part of a critical load-bearing sequence. Ensure everyone knows that once a post is pinned and tensioned, it stays that way until the engineer says otherwise.

Investing in high-quality, galvanized heavy duty shoring posts might hurt the budget today, but it’s a lot cheaper than a structural collapse and an OSHA investigation that shuts your site down for six months. Stick to the steel, trust the math, and keep your site standing.