Ever tried scanning a menu in a dimly lit cocktail bar? It sucks. You’re squinting, pulling out your phone flashlight, and blinding everyone at the table just to see the price of a Negroni. This is exactly where the glow in the dark QR code enters the chat. It sounds like something pulled straight from a 90s rave or a sci-fi flick, but it’s becoming a legitimate tool for businesses that operate when the sun goes down. We aren't just talking about stickers that look cool; we're talking about photoluminescent tech that bridges the gap between physical darkness and digital access.

It’s niche. It’s weird. Honestly, it's pretty clever.

The Science of Making Pixels Glow

Most people think "glow in the dark" and imagine those cheap plastic stars they had on their ceiling as a kid. That's strontium aluminate. It’s a phosphorescent material that absorbs photons and spits them back out slowly over time. When you apply this to a glow in the dark QR code, you aren't just printing on neon paper. You are essentially creating a self-powering light source for the data.

The technical hurdle is contrast. A QR code works because the scanner sees the difference between the dark "modules" and the light background. If the whole thing glows too brightly, the "quiet zone"—that's the technical term for the border around the code—gets washed out. You need the black bits to stay deep black while the light bits emit enough luminance to be picked up by a smartphone CMOS sensor. Companies like Glow-V or specialized industrial label manufacturers use high-grade phosphorescent pigments that can maintain a readable contrast for up to eight hours. It’s a delicate balance. If the glow is too weak, the camera sees nothing. If it’s too strong, the light bleeds into the black squares, causing a "blooming" effect that breaks the data string.

Where People Are Actually Using This

Nightclubs are the obvious playground. Think about it. You’re in a basement in Berlin or a rooftop in Brooklyn. It’s pitch black. You want to see the lineup or order a drink without a paper menu. A glow in the dark QR code printed on the table or a wristband solves the lighting issue without needing a backlight or an expensive LED screen.

📖 Related: Microsoft Certified: Azure AI Fundamentals Explained (Simply)

Safety is the other big one. In industrial settings, OSHA (Occupational Safety and Health Administration) has strict rules about egress and emergency information. If the power goes out in a warehouse, you don't want to be searching for a manual. A photoluminescent QR code on a fire extinguisher or an exit door can lead a worker directly to a digital map or safety instructions on their phone, even in total darkness. It’s basically a backup system that doesn't require batteries.

Then you have the marketing "cool factor." Brands like Heineken or Coca-Cola have experimented with limited edition packaging that features glowing elements. It’s high-friction to get someone to scan a code normally, but if the code itself is glowing in their hand at a concert? The scan rate jumps. Curiosity is a hell of a drug.

The Scannability Problem (and How to Fix It)

Can you actually scan these things? Sometimes.

If you use a standard 2D barcode scanner app on an older iPhone, you might struggle. The sensor needs to find those three "position detection patterns" (the big squares in the corners). Most modern phones use computational photography to boost low-light images instantly. This is a lifesaver for the glow in the dark QR code. When you point your camera at it, the phone's software kicks in, increases the ISO, and clarifies the edges of the glow.

To make it work, you have to follow specific design rules:

- Higher Error Correction: You need to set the QR code’s ECC (Error Correction Code) to Level H or Q. This allows the code to be read even if 25% to 30% of it is obscured or "blown out" by the glow.

- Large Module Size: Tiny, complex codes are a nightmare. You want big, chunky blocks.

- Surface Texture: Matte finishes are better. Glossy surfaces create "hot spots" from the phone's own screen light, which reflects back and confuses the sensor.

Myths and Misconceptions

People think these things stay bright forever. They don't. This isn't tritium—the radioactive stuff in high-end watches that glows for 20 years. Phosphorescence is a battery that needs a recharge. If a glow in the dark QR code is stuck in a dark hallway for three days, it’s just a gray square. It needs exposure to UV light or even standard ambient light to "prime" the pigment.

Another misconception is that you can just print these on a home inkjet printer. You can't. Standard ink is translucent. You need specialized, opaque screen-printing inks or vinyl layering. If you try to DIY this with a glow-in-the-dark spray can, you'll just end up with a blurry mess that your phone won't recognize as a link. It’ll just look like a radioactive Rorschach test.

Sustainability and Durability

From a business perspective, the longevity of the material is a huge plus. High-quality strontium aluminate doesn't "wear out" quickly. It can go through thousands of charge and discharge cycles without losing significant luminosity. This makes a glow in the dark QR code a one-time investment for wayfinding or outdoor signage.

Compare that to an electronic e-ink display or a backlit LED frame. Those require wiring, electricity, and maintenance. The glowing code just sits there. It’s passive. In a world where everyone is obsessed with "ESG" goals and reducing energy footprints, using physics instead of electricity to display information in the dark is a weirdly elegant solution.

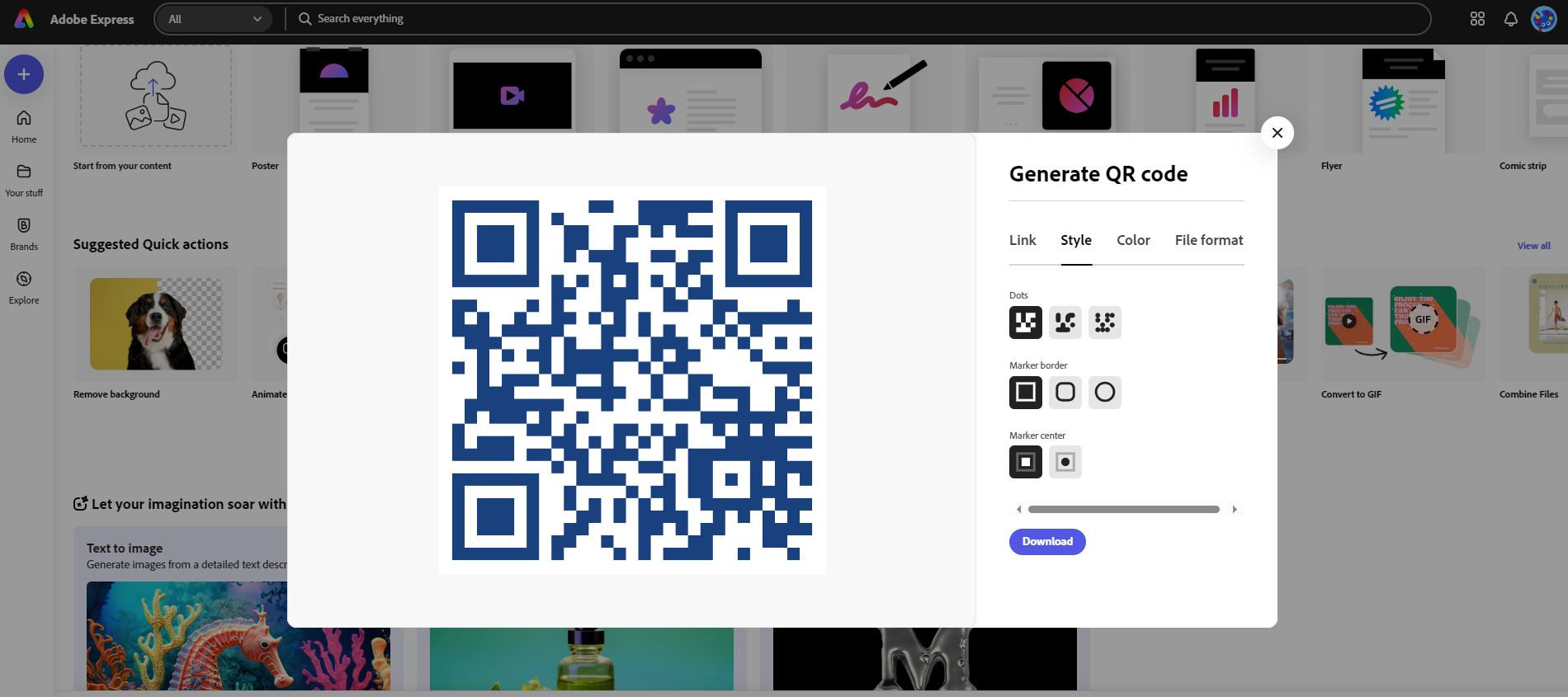

How to Get Started with Photoluminescent Codes

If you’re looking to implement this, don't start with the printing. Start with the logic. Use a dynamic QR code rather than a static one. Why? Because the physical printing of a glow in the dark QR code is expensive. If you print 500 signs for a music festival and the URL changes, you're screwed. A dynamic code lets you change the destination link in the backend without touching the glowing physical sign.

Next, find a specialist printer. You're looking for someone who deals in "Safety Grade" photoluminescent vinyl. This stuff is regulated and tested for how long it stays visible.

Actionable Next Steps

- Test Your Environment: Use a light meter app to see exactly how dark your space is. If there’s zero ambient light to "charge" the code, you’ll need to install a small UV "blacklight" nearby to keep it primed.

- Opt for High Contrast: Always use black ink on the glowing substrate. Never try to make the "black" parts glow and keep the background dark. It confuses the inversion logic of most smartphone cameras.

- Use a Simple URL: The more data you cram into a QR code, the smaller the squares get. Use a URL shortener or a dynamic platform to keep the code "low density." This makes it much easier to scan in the dark.

- Prototype First: Print one. Take it into a closet. Try to scan it with a three-year-old Android and a brand-new iPhone. If the Android fails, your design is too complex.

The glow in the dark QR code isn't just a gimmick. It’s a functional response to the fact that we use our phones 24/7, but the world isn't always lit for our convenience. Whether it's for a "speakeasy" vibe or literal life-saving information in a power outage, these glowing squares are proving that sometimes, the best tech is just a bit of clever chemistry.