Walk into the General Motors St. Catharines Propulsion Plant on a Tuesday morning and you’ll hear a specific kind of industrial hum that hasn’t stopped for decades. It’s loud. It’s consistent. It’s the sound of thousands of people making sure your truck actually moves when you hit the gas. Most folks driving down the QEW past the Glendale Avenue exit see the massive grey buildings and the sprawling parking lots, but they don't really grasp how much of the North American automotive backbone is forged right there in Niagara.

It’s a survivor.

While other Ontario plants shuttered or shifted to assembly, General Motors St. Catharines stayed focused on the "guts"—engines and transmissions. It’s one of the few places where you can still feel the raw power of the old-school automotive industry, even as the walls start to vibrate with the high-voltage hum of the future. Honestly, if you want to understand why GM is betting so hard on a mix of gas-guzzling power and electric efficiency, this is the place to look.

The V8 Engine is Still King (For Now)

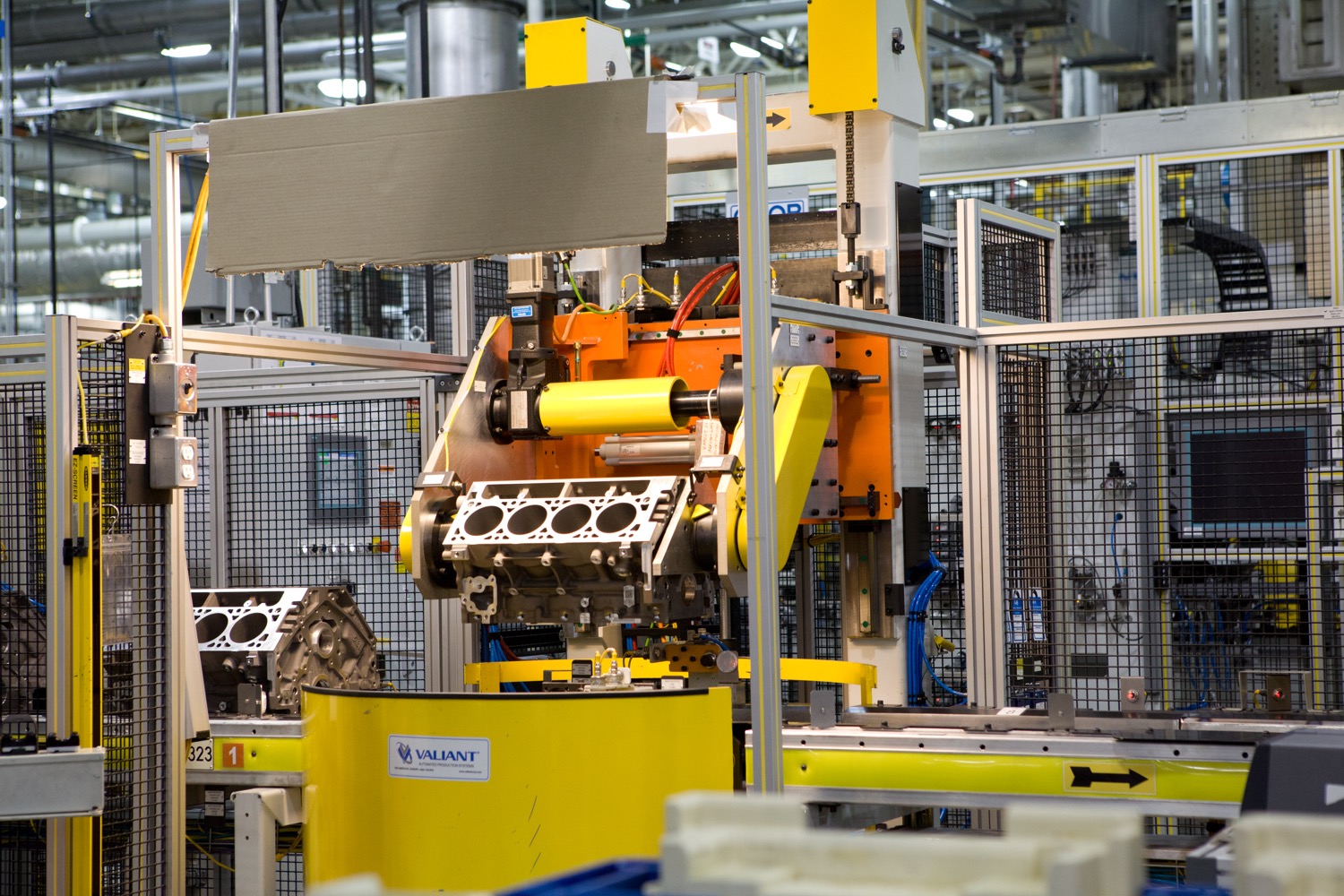

Let’s get one thing straight: the internal combustion engine isn't dead at Glendale. Far from it. This plant is the primary source for the Gen V Small Block V8. We’re talking about the 5.3L and 6.2L engines that end up in the Chevrolet Silverado, the GMC Sierra, and the Cadillac Escalade. These are the profit centers for General Motors. Without the engines coming out of St. Catharines, the company's entire truck strategy falls apart.

The scale is staggering.

Workers here have been refining the art of the engine block for years, and the precision is wild. You’ve got robots doing the heavy lifting, sure, but the human eye is still the final gatekeeper for quality. There’s a certain pride in Niagara about this. You’ll meet families where three generations have worked the line. Grandpa built the old 350s, Dad worked on the Northstar, and now the grandkids are monitoring CNC machines for the latest LT series.

But it isn't just about the V8s anymore.

The Massive Shift to EV Drive Units

In 2023, the narrative changed. GM announced a massive investment—over $280 million—to bring electric vehicle (EV) drive unit production to St. Catharines. This was a pivot. A big one. Instead of just casting blocks and machining crankshafts, the plant is prepping to build the "motors" for the Ultium platform.

Basically, the plant is being split down the middle. One side is the thumping heart of the gasoline era, and the other is becoming a high-tech clean room for electric propulsion. It’s a weird contrast. You can practically smell the cutting fluid on one end and see the sterile, laboratory-like environment being built on the other.

The goal? Support the production of 1 million EVs in North America. St. Catharines is slated to produce hundreds of thousands of these drive units annually. It’s a hedge against the future. If the world goes all-electric, the plant is safe. If people keep buying V8 trucks for another twenty years, the plant is still safe. It’s a brilliant, albeit stressful, balancing act for the local Unifor Local 199 members.

Why the Location Matters

St. Catharines isn't just some random spot on a map for GM. It’s a logistical goldmine. Being right near the Welland Canal and the US border means parts move fast. You have a direct line to assembly plants in Oshawa and across the border in Michigan.

The Glendale plant—officially known as the St. Catharines Propulsion Plant—sits on about 140 acres. It has survived the 2008 financial crisis, the COVID-19 supply chain nightmares, and the 2023 strikes. Every time people count it out, the plant lands a new contract.

The Reality of the Workforce

Working at General Motors St. Catharines isn't just a job; it’s a lifestyle. It’s shift work. It’s midnights. It’s overtime when the trucks are selling well and "layoff anxiety" when the economy dips.

The relationship between the union and the company here is legendary. Unifor Local 199 is incredibly active. They’ve fought for every cent and every safety protocol in that building. When you talk to the workers, they’ll tell you it’s hard work. It’s physically demanding, even with the modern automation. But it’s also one of the last places in Ontario where a person can get a solid middle-class life without a four-year university degree.

- Total Employment: Usually hovers around 1,100 to 1,500 depending on the current production cycles.

- Main Products: V8 engines, GF6 transmissions, and upcoming EV drive units.

- Economic Impact: It’s estimated that for every one job inside the GM plant, there are roughly 6-7 spinoff jobs in the Niagara region.

Think about the parts suppliers, the trucking companies, the local diners, and even the real estate market. If GM St. Catharines catches a cold, the whole city starts sneezing.

Common Misconceptions About the Plant

People often think the plant is "closing soon" because of the push toward green energy. This couldn't be further from the truth. In fact, the recent investments have given the plant its longest "visibility" into the future in years.

Another myth is that it’s all robots now. While the automation is impressive—think robotic arms precisely applying gaskets or measuring tolerances to the micron—the complexity of an engine assembly still requires human dexterity and problem-solving. A robot can’t "feel" if a bolt is cross-threaded the way a veteran line worker can.

🔗 Read more: Ace Hardware Dallas Bay: Why Local Knowledge Still Beats Big Box Stores

Then there's the environmental side. You’d think an engine plant is a massive polluter, but GM has actually pushed the St. Catharines site toward some pretty serious sustainability goals. They’ve implemented massive landfill diversion programs and updated their cooling systems to be more efficient. It’s not a forest, obviously, but it’s not the 1950s smokestack nightmare people imagine either.

The EV Transition: A Risk or a Reward?

The transition to EV drive units is scary for some. Electric motors have significantly fewer moving parts than an internal combustion engine. Fewer parts usually means fewer people needed to put them together.

However, the sheer volume of expected EV production might offset that. GM is betting that by diversifying the St. Catharines output, they can protect the site from market volatility. If gas prices spike and truck sales tank, the EV line picks up the slack. It’s a diversification strategy that has essentially "future-proofed" the Niagara footprint.

What This Means for the Niagara Region

If you live in St. Catharines, Welland, or Niagara Falls, the health of this plant affects your property value. Period. The high-paying jobs provided by GM allow people to buy homes and spend money locally.

The city has grown around the plant. What used to be the outskirts is now a bustling hub near the Pen Centre and Brock University. The synergy between the plant and the local community is deep-rooted. You see the GM logo on local hockey jerseys and at charity events. It’s woven into the fabric of the place.

Actionable Insights for the Future

If you're looking at General Motors St. Catharines from a business or employment perspective, keep these points in mind:

1. Watch the Retraining Trends

The biggest opportunity for current and prospective workers is in high-tech manufacturing and electrical systems. As the EV lines ramp up, the demand for technicians who understand power electronics over traditional mechanics will skyrocket.

2. Follow the Supply Chain

Business owners in Niagara should look at how the shift to EV drive units changes the needs for secondary suppliers. Different materials, different chemicals, and different shipping requirements are coming.

3. Real Estate Stability

The 2023 investment announcement essentially locked in the plant’s relevance for the next decade. For those worried about the regional economy, this is a massive green flag for long-term stability in the Glendale area.

4. Monitor the Oshawa Connection

The St. Catharines plant is inextricably linked to the Oshawa Assembly plant. When Oshawa adds a third shift to build more Silverados, St. Catharines hums. When you see news about GM’s truck sales in the US, that is the leading indicator for how busy the Glendale plant will be.

The St. Catharines Propulsion Plant is a testament to the fact that you can teach an old dog new tricks. It’s a heavy-metal, grease-stained relic that is somehow also becoming a high-tech hub for the next generation of transportation. It’s complicated, it’s noisy, and it’s the most important building in the Niagara region.