You're standing at the workbench with a piece of 1084 high-carbon steel and a Sharpie. It’s a big moment. But then you realize that drawing a radius by hand—especially one that actually fits a human grip—is way harder than it looks on YouTube. Honestly, most beginners ruin their first few blades because they wing the geometry. That’s why free printable knife patterns are a literal lifesaver for the hobbyist bladesmith. They take the guesswork out of the "is this going to feel like a brick in my hand?" phase of the build.

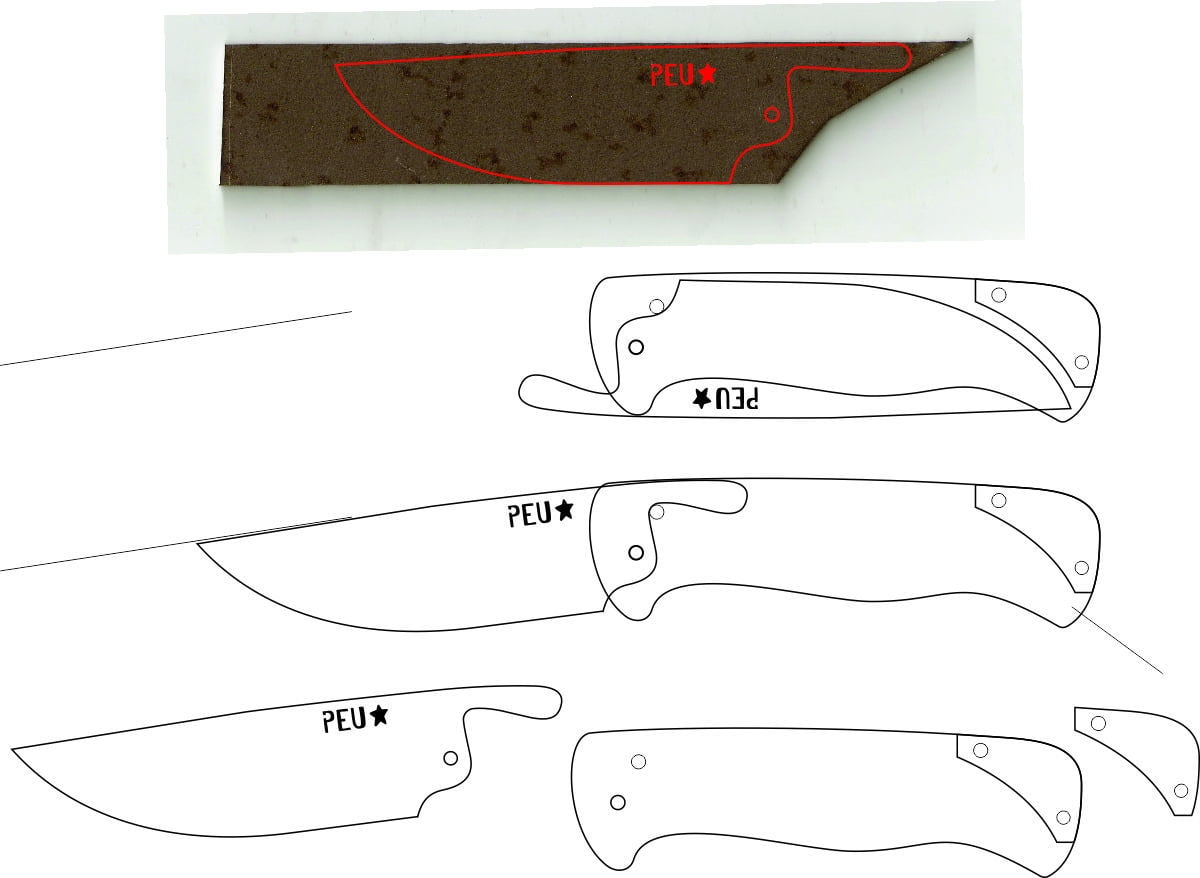

Most people think a pattern is just a shape. It's not. It is a blueprint for center of mass, edge geometry, and ergonomic safety. If your finger choil is two millimeters too shallow, you're going to slip and cut yourself. If the tang is too thin, the knife snaps under lateral stress. Using a pre-designed template isn't "cheating." It's using engineering that’s already been proven to work in the field.

Why Paper Templates Save Your Steel (and Your Sanity)

Steel isn't cheap. Whether you’re buying precision-ground stock from New Jersey Steel Baron or scavenging old leaf springs from a scrapyard, you don't want to waste material. A paper pattern lets you "test drive" the knife before you ever touch a grinder.

I always tell people to glue their free printable knife patterns onto a piece of cardboard or thin plywood first. Cut it out. Hold it. Try to "cut" an imaginary steak or feather-stick a piece of wood. You’ll immediately notice if the handle is too short for your pinky or if the drop point is too aggressive for your intended use. It’s a lot easier to fix a paper drawing with a pencil than it is to fix a heat-treated blade with a belt sander. You can’t put metal back on once it’s gone.

💡 You might also like: Is the Sam's Club Bogg Bag Alternative Actually Worth Your Money?

There are some legendary makers who have shared their designs over the years. Guys like Tom Halloran or the folks over at BladeForums often drop PDF templates for classic EDC (Everyday Carry) designs. These aren't just random drawings; they are refined shapes honed through years of professional making. Using these resources gives you a massive head start on understanding "blade-to-handle" ratios.

Finding the Right Free Printable Knife Patterns for Your Skill Level

Don't go trying to make a complex recurve kukri on your first go. Seriously. You’ll hate yourself by the time you reach the plunge lines.

The Beginner’s Best Friend: The Full-Tang Bushcraft Blade

If you are just starting, look for a simple drop-point bushcraft design. These are basically the "Hello World" of knifemaking. The lines are clean, the tang is full (meaning the steel goes all the way through the handle), and there are no complex guards or bolsters to fit. A classic Kephart-style pattern is perfect here. It's a utilitarian 4-inch blade that has been a staple in the woods for over a century because it just works.

The Tactical Tanto and the EDC Wharncliffe

Once you've got a couple of builds under your belt, you might want something with more "attitude." Tantos are popular because they are relatively easy to grind—most of the lines are straight. However, a Wharncliffe pattern is arguably more useful for 90% of what people actually do with knives, like opening boxes or cutting cordage. When looking for free printable knife patterns for these, pay attention to the pin hole locations. If the holes are too close to the edge of the tang, your handle scales will crack.

The Technical Side: Printing to Scale

This is where most people mess up. They download a beautiful PDF, hit print, and end up with a knife that looks like it belongs to a GI Joe action figure.

🔗 Read more: Name on Hand Tattoo: Why This Trend Still Sparks So Much Drama

Most digital patterns are designed for 8.5" x 11" paper, but printers love to "scale to fit." You have to check your printer settings. Set the scale to 100%. Don't let it "shrink to fit" or add extra margins. A good way to verify this is to look for a "scale key" on the pattern—usually a 1-inch or 5-cm line printed in the corner. Take a ruler to that line immediately after printing. If it's 15/16ths of an inch, your whole knife is going to be wonky.

Common Mistakes in Template Selection

- The "Mall Ninja" Trap: Choosing patterns with serrations, weird spikes, or five different finger grooves. These are a nightmare to grind and rarely feel good in the hand.

- Ignoring Stock Thickness: A pattern designed for 1/8 inch steel might feel "flimsy" if you try to make it out of 1/4 inch stock. The ergonomics change as the knife gets wider.

- Forgetting the Sheath: A knife is only half the project. If you choose a pattern with a massive guard, making a Kydex or leather sheath for it becomes ten times harder.

Real-World Advice from the Shop

I remember talking to a veteran maker at a hammer-in a few years ago. He said the biggest mistake he sees is people "over-designing." They want a knife that does everything. But a knife that tries to be a chopper, a slicer, and a pry bar usually ends up being bad at all three. Stick to a dedicated purpose.

When you use free printable knife patterns, you are essentially standing on the shoulders of the makers who came before you. You're learning the "visual language" of a good knife. Eventually, you’ll start tweaking those patterns. You’ll move a pin hole here, or extend the belly of the blade there. That’s how you develop your own style. But start with the basics.

📖 Related: Schlossberg Family's Chapel on the Hill Obituaries: What Most People Get Wrong

Also, consider the "grindability." A hollow grind requires a contact wheel on your 2x72 grinder. A flat grind is easier with a platen. If the pattern you downloaded has a very high grind line and you're working with a file jig, be prepared to spend about forty hours of manual labor on that one bevel. Choose a pattern that matches the tools you actually have in your garage.

Moving From Paper to Steel

Once you have your template perfectly sized and cut out, use a spray adhesive (like 3M 77) to stick it directly onto the steel. Don't just trace it. Tracing with a marker adds thickness to the line, and "cutting the line" versus "leaving the line" can change the dimension of the knife by a noticeable margin. If you glue the paper down, you can grind right up to the edge of the paper for a precision fit.

Some makers prefer to use a scribe to scratch the outline into the steel. This is great because the paper won't catch fire or peel off when the steel gets hot during the profile grinding. If you go this route, a bit of layout fluid (Dykem Steel Blue) makes your scribed lines pop so you aren't squinting through your safety glasses.

Actionable Steps for Your Next Build

- Download three different styles: Get a drop point, a tanto, and a small paring knife pattern. Even if you only plan to make one, comparing the handle shapes will teach you a lot about ergonomics.

- Print at "Actual Size": Verify with a physical ruler. If it’s off by even a tiny bit, the pin holes for your handle won't line up with standard hardware.

- The Cardboard Test: Glue the pattern to a cereal box and cut it out. Spend five minutes holding it. If it feels "off" in your palm now, it will feel worse when it's made of hardened steel.

- Check your drill bits: Before you start grinding, make sure you actually have the drill bits that match the pin holes on the pattern (usually 1/8", 3/16", or 1/4").

- Trace the "ricasso" area carefully: This is the unground portion of the blade between the handle and the sharpened edge. It's the most common place for beginners to mess up, so make sure your pattern clearly defines where the grind starts.

Bladesmithing is a journey of a thousand mistakes, but using a solid pattern helps you skip the first five hundred. Grab some paper, find a design that speaks to you, and get to work. The steel is waiting.