Math is weirdly circular. You're staring at a metal pipe, a soda can, or maybe a massive industrial silo, and you need to know the width from the center out. But you don't have a ruler that can teleport into the middle of a solid object. That is exactly where the formula radius of cylinder calculations save your life. Or at least your weekend project. Most people just want a quick answer, but the reality is that the "formula" depends entirely on what information you're holding in your hands right now.

Are you looking at the volume? Do you only know the surface area? It changes everything.

The Basics (The "I Have the Diameter" Scenario)

Let’s start with the easy stuff. If you can measure all the way across the circular face of the cylinder, you have the diameter. Finding the radius is just cutting that number in half.

$r = \frac{d}{2}$

It's simple. Almost too simple. But in the real world—like if you're a civil engineer working with the American Society of Civil Engineers (ASCE) standards—you rarely get a clean diameter measurement on an existing structure. You usually have to work backward from other properties.

💡 You might also like: FBI Warning iPhone Android Text Scams: What the Feds Want You to Delete Right Now

When You Only Know the Volume: The Reverse Engineering Trick

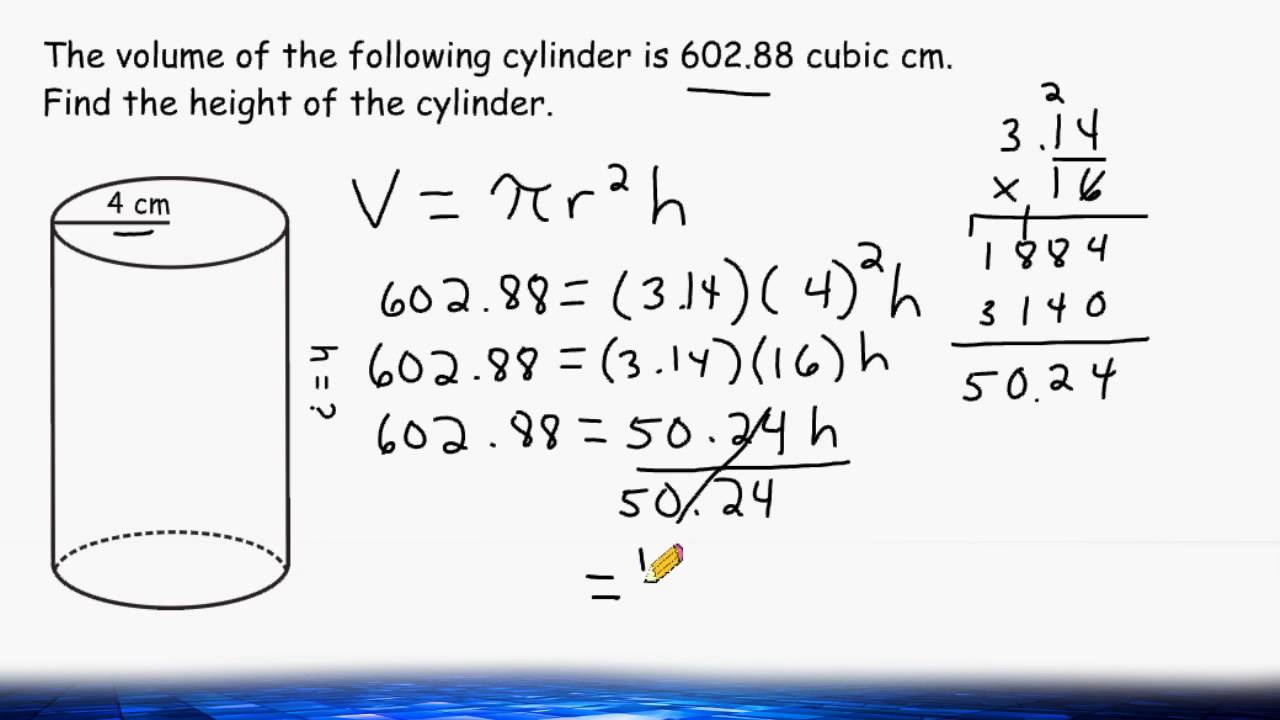

This is where things get interesting. Imagine you know a tank holds exactly 500 gallons of water. You know how tall it is. How do you find the radius? You have to tear apart the standard volume formula.

The standard volume of a cylinder is $V = \pi r^2 h$. To get the formula radius of cylinder out of that mess, you have to do some algebraic gymnastics. You divide the volume by $\pi$ times the height, and then—this is the part everyone forgets—you take the square root of the whole thing.

$$r = \sqrt{\frac{V}{\pi h}}$$

Let’s be real: nobody does this in their head. If you have a cylinder with a volume of $100 cm^3$ and a height of $5 cm$, you're looking at $100$ divided by $15.7$ (which is roughly $5 \times 3.14$). That gives you $6.36$. The square root of that is about $2.52 cm$.

📖 Related: Food Lion App for Android: Why Your Local Grocery Run Just Got Way Smarter

Why the "Squaring" Matters

People mess this up constantly because they forget that the radius is squared in the original equation. If you double the radius, you don't double the volume. You quadruple it. This is why small changes in the radius of a pipe lead to massive changes in how much fluid it can carry. If you're plumbing a house, a tiny mistake in calculating the radius of a drain pipe means the difference between a clear sink and a flooded basement.

The Surface Area Headache

Honestly, using surface area to find the radius is a nightmare. It’s the "final boss" of cylinder math. The total surface area ($A$) includes the two circular caps and the side wall (the lateral area).

$A = 2\pi r^2 + 2\pi rh$

Notice anything? You have $r^2$ and $r$ in the same equation. That’s a quadratic equation. To solve for the formula radius of cylinder here, you basically have to use the quadratic formula. It's messy. It's gross.

Most tradespeople don't bother with the math. They use a lookup table or an app. But if you're stuck in the field without a signal, you’re looking for the positive root of $2\pi r^2 + 2\pi rh - A = 0$.

Practical Variations You'll Actually Use

- The String Method: If you wrap a string around the cylinder, you get the circumference ($C$). The radius is just $C / 2\pi$. This is honestly the most accurate way to do it in a workshop.

- The Displacement Method: Drop the cylinder in water. Measure how much the water rises (Volume). Use the height of the cylinder to work back to the radius.

- The Weight Method: If you know the material (like steel) and the total weight, you can find the volume using density ($\rho = m/V$), then solve for $r$.

Real-World Nuance: It’s Never a Perfect Cylinder

In a classroom, cylinders are perfect. In reality, they're tapered, dented, or "out-of-round." If you are measuring a piston for an engine rebuild, "radius" isn't one number. It’s an average of multiple measurements taken at different points.

Mechanical engineers use tools like micrometers to measure the diameter at the top, middle, and bottom. If these numbers vary, the cylinder is "tapered." If the diameter is different when you rotate the tool 90 degrees, the cylinder is "oval." In these cases, the formula radius of cylinder becomes a statistical average rather than a geometric certainty.

Common Pitfalls to Avoid

Don't mix your units. It sounds like Advice 101, but you'd be shocked how many people try to plug inches of height and gallons of volume into the same equation. Always convert everything to a single metric or imperial base before touching the formula.

Also, watch your $\pi$. Using $3.14$ is fine for a birdhouse. If you're calculating the fuel capacity for a SpaceX Starship (which is basically just a giant series of cylinders), $3.14$ isn't nearly precise enough. You need at least 10 decimal places to prevent the math from drifting over large scales.

Getting It Done: Your Action Plan

If you're staring at a project right now and need the radius, follow these steps:

📖 Related: Weather Radar Shrewsbury MA: What Most People Get Wrong About Tracking Central Mass Storms

- Identify your "Knowns": Do you have Volume, Surface Area, or just a piece of string?

- Strip the "Caps": If you're measuring a hollow pipe, remember the difference between the inner radius and the outer radius. The wall thickness matters.

- The Circumference Hack: If the cylinder is large, measure the distance around it. Divide that by $6.28$. That is your radius. It's the fastest way with the least amount of error.

- Check for Taper: Measure at both ends. If the numbers aren't the same, your cylinder is actually a frustum of a cone, and these formulas won't work perfectly.

Calculating the formula radius of cylinder isn't about memorizing a string of symbols. It's about knowing which tool to grab when the situation changes. Whether you are calculating the volume of a hydraulic ram or just trying to figure out if a pancake batter will fit in a tin, start with the circumference if you can. It’s the hardest one to mess up.

Once you have your radius, double-check it by calculating the diameter and physically holding a ruler up to the object. If the math says the radius is 5 inches but your ruler shows the whole thing is only 8 inches wide, you forgot to divide by $\pi$ or missed a square root somewhere. Trust your eyes over your calculator every single time.