Ever stared at those tiny black lines on a wooden stick and felt your eyes go blurry? You aren’t alone. Most people look at a standard Imperial ruler and see a chaotic mess of hash marks that don’t seem to make much sense at first glance. But honestly, once you find 3/8 inch on a ruler, the whole system starts to click. It’s that sweet spot. Not quite a half-inch, a bit more than a quarter.

Precision matters. If you’re hanging a heavy mirror or cutting a piece of trim for a DIY flooring project, being off by an eighth of an inch is the difference between a job well done and a ruined piece of expensive oak. We’ve all been there. You measure twice, cut once, and it’s still too short. Why? Usually, it's because those middle-tier fractions like 3/8 or 5/8 are where the brain starts to guess instead of count.

The Secret Language of Ruler Lines

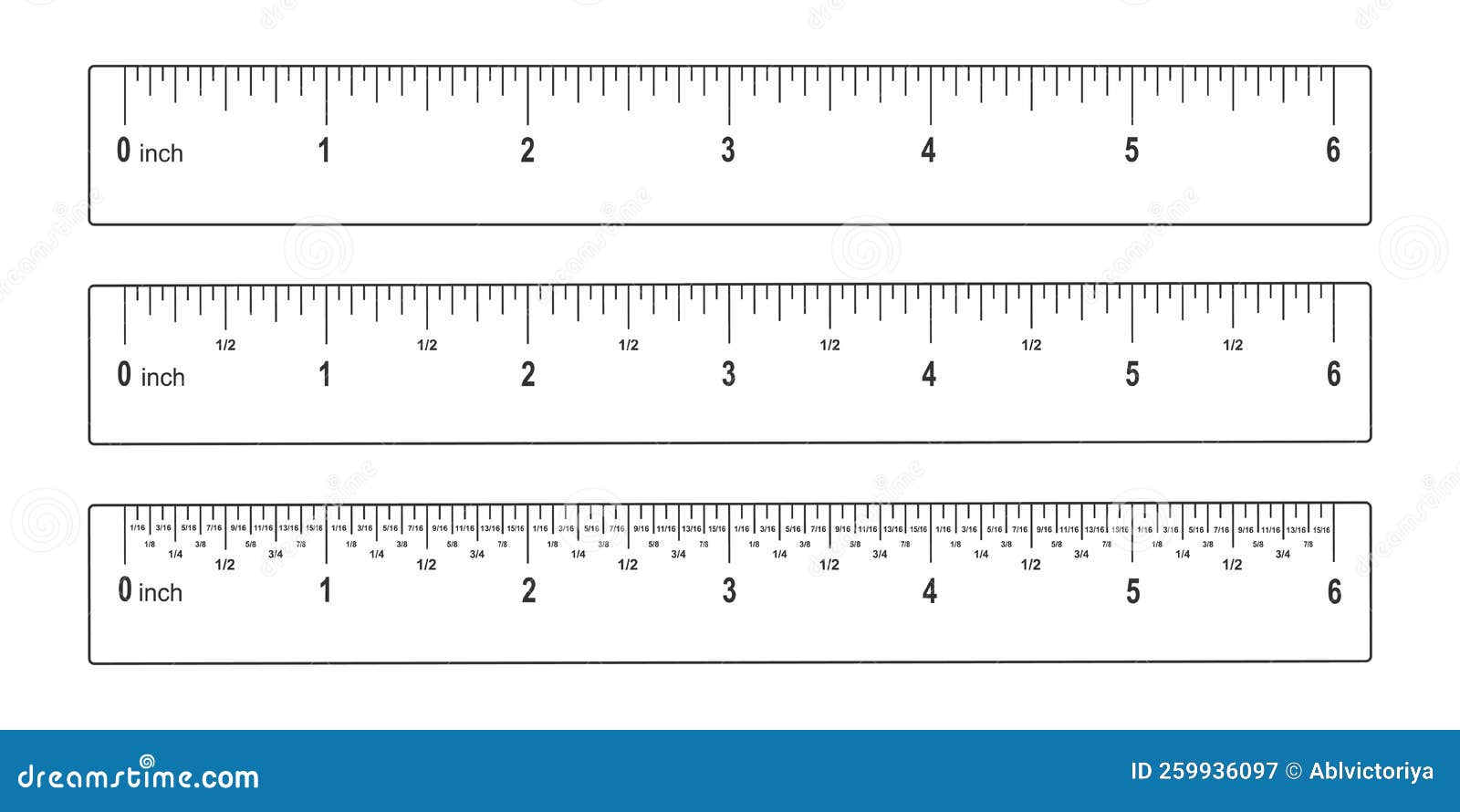

Rulers have a rhythm. Think of it like music. The longest lines are the full inches. They’re the anchors. The second-longest line right in the middle? That’s your half-inch mark.

To find 3/8 inch on a ruler, you have to look at the eighth-inch marks. These are typically the third-longest lines on a standard US ruler. If you look at the space between the 0 and the 1-inch mark, you’ll see several different heights of lines. The quarter-inch marks are slightly longer than the eighths.

Here is how you actually find it without counting every single tiny tick like a maniac. First, find the quarter-inch mark ($1/4$). We know that $1/4$ is the same as $2/8$. So, the very next "medium-short" line after the quarter-inch mark is your 3/8. It’s literally just one "eighth" jump past the first quarter.

🔗 Read more: What Does Dulce Mean in Spanish? It Is More Than Just Candy

If you prefer counting from the half-inch mark ($1/2$), just go backward. Since $1/2$ is the same as $4/8$, you just move one eighth-inch tick to the left. Boom. There it is. 3/8.

Why 3/8 Inch Is Everywhere in Your House

You might think 3/8 is some obscure measurement, but it’s actually a standard in the construction and hardware world.

Take plumbing, for instance. A very common size for supply lines—the flexible metal hoses that connect your toilet or sink faucet to the wall valve—is 3/8 inch compression. If you buy a 1/2 inch line by mistake, it won't fit, and you'll be heading back to the hardware store in a bad mood.

It’s also a massive deal in the world of power tools.

- Drill Chucks: Many older or compact drills have a 3/8-inch chuck. This determines the maximum diameter of the drill bit shank you can shove in there.

- Socket Wrenches: This is the "Goldilocks" size. A 1/4-inch drive is for tiny electronics; a 1/2-inch drive is for heavy-duty automotive work. The 3/8-inch drive is the king of the DIY garage. It handles almost everything on a standard car engine or lawnmower.

- Dowels and Bolts: If you’re assembling furniture, 3/8-inch wooden dowels are a frequent flyer because they offer enough surface area for glue without weakening the surrounding wood too much.

Visualizing the Fractions

Let’s get real about the math for a second, but keep it simple. If you’re looking at a ruler that is divided into 16ths (which most are), 3/8 inch on a ruler is the same as 6/16.

Counting sixteen tiny lines is a nightmare. Don't do that. Instead, recognize that the ruler is a hierarchy.

- The 1-inch mark is the "boss."

- The 1/2-inch mark is the "manager."

- The 1/4 and 3/4 marks are the "supervisors."

- The 1/8, 3/8, 5/8, and 7/8 marks are the "team leads."

Most people can spot the 1/4 and 1/2 marks instantly. Since 3/8 is exactly halfway between 1/4 and 1/2, it’s easy to find once you stop looking at the ruler as a wall of lines and start looking at it as a series of neighborhoods.

Common Mistakes When Measuring

The "Hook" error is a big one. You know that metal tip at the end of a tape measure that wiggles? People think it’s broken. It’s not. It’s supposed to move. That movement accounts for the thickness of the metal hook itself. If you’re pulling the tape against a board, the hook pulls out to include its own thickness in the measurement. If you’re pushing it against a wall, it slides in to exclude its thickness.

If you try to find 3/8 inch on a ruler starting from the "1" mark instead of the "0" (a trick called "burning an inch" for better accuracy), you have to remember to do the math. Your 3/8 mark will actually be at 1 and 3/8. You’d be surprised how many professional contractors have cut a board exactly one inch too short because they forgot they were burning an inch.

Another weird thing? Parallax error. If you look at the ruler from an angle, you’ll misread the line. You have to look straight down at the 3/8 mark. If you're leaning to the left, you might actually be marking 5/16. If you're leaning right, you might hit 7/16.

The Metric Conversion Trap

Sometimes you’re working with a project that uses millimeters. If you’re trying to find the metric equivalent of 3/8 inch on a ruler, you’re looking at roughly 9.525 mm.

In the real world, like if you're looking for a wrench, a 10mm wrench is "close" but often loose enough to round off a 3/8-inch bolt head. This is why having both SAE (Imperial) and Metric tools is a necessity rather than a luxury. You can’t just "close enough" your way through a 3/8 measurement.

Practical Application: The 3/8 Drill Bit

If you’re hanging a TV mount and the instructions say to use a 3/8-inch drill bit for the wall anchors, they mean it. A 1/4-inch hole will be too small, and you'll end up destroying the plastic anchor trying to hammer it in. A 1/2-inch hole will be too big, and the anchor will just spin in circles, eventually pulling out and sending your expensive OLED crashing to the floor.

When you pick up a drill bit, the size is usually stamped on the shank. But those stamps wear off. If you’re unsure, lay the bit down on your ruler. The widest part of the twisted flutes should line up exactly with that third "eighth" mark—the one just past the quarter-inch.

Digital vs. Analog Measurement

We live in a world of digital calipers now. They’re great. You slide them open, and a screen tells you 0.375.

Wait. 0.375?

Yeah, that’s the decimal version of 3/8.

$3 \div 8 = 0.375$.

If you are using a digital tool and it reads 0.37, you’re basically there. If it reads 0.31, you’re at 5/16. If it reads 0.43, you’re at 7/16. Knowing these decimal equivalents is a lifesaver when you're shopping at a hardware store where some items are labeled in decimals and others in fractions.

Better Ways to Mark Your Work

When you finally find that 3/8 mark, don’t just draw a straight line. Pros use a "crow's foot." You draw a tiny "V" where the point of the V is exactly on the 3/8 mark. This is way more accurate than a thick pencil smudge that could cover three different sixteenth-inch increments.

Also, use a sharp pencil. A dull carpenter’s pencil can be 1/16 of an inch wide. If you mark on the wrong side of your 3/8 line with a fat pencil, your final piece won't fit.

Real-World Practice

Go grab a ruler right now. Find the 0. Find the 1. Now, find the halfway point. Okay, move your eye to the left to the 1/4 mark. Now, look at that one lonely line sitting right between the 1/4 and the 1/2. That’s your 3/8.

It’s the size of a standard large ibuprofen tablet. It’s roughly the width of a slim smartphone. It’s a very "human" scale measurement.

Summary of Actionable Steps

To master the 3/8 measurement in your daily projects, start by verifying your equipment. Not all rulers are created equal; cheap plastic ones can actually be slightly off due to poor manufacturing.

- Check for Parallax: Always look dead-on at the ruler, not from the side.

- Identify the Hierarchy: Train your eyes to see the 1/4 and 1/2 marks first, then find the 3/8 between them.

- Memorize the Decimal: Remember that 0.375 is your target number when using digital tools or calculators.

- Use a Crow's Foot: Mark your measurements with a V-shape for surgical precision.

- Verify the Tool: If using a 3/8-inch socket or bit, check the engraving on the side to ensure it hasn't been swapped into the wrong slot in your toolbox.

Understanding this specific increment takes the guesswork out of assembly and repair. Once you stop fearing the fractions, you can build just about anything.