It's tiny. Really tiny. If you’re staring at a ruler trying to figure out how long is 2mm in inches, you’re probably in the middle of a project that requires a ridiculous amount of precision. Maybe you’re measuring the thickness of a guitar pick, the gauge of a piercing, or the gap in a spark plug. Whatever it is, you've realized that the metric and imperial systems don't exactly play nice together.

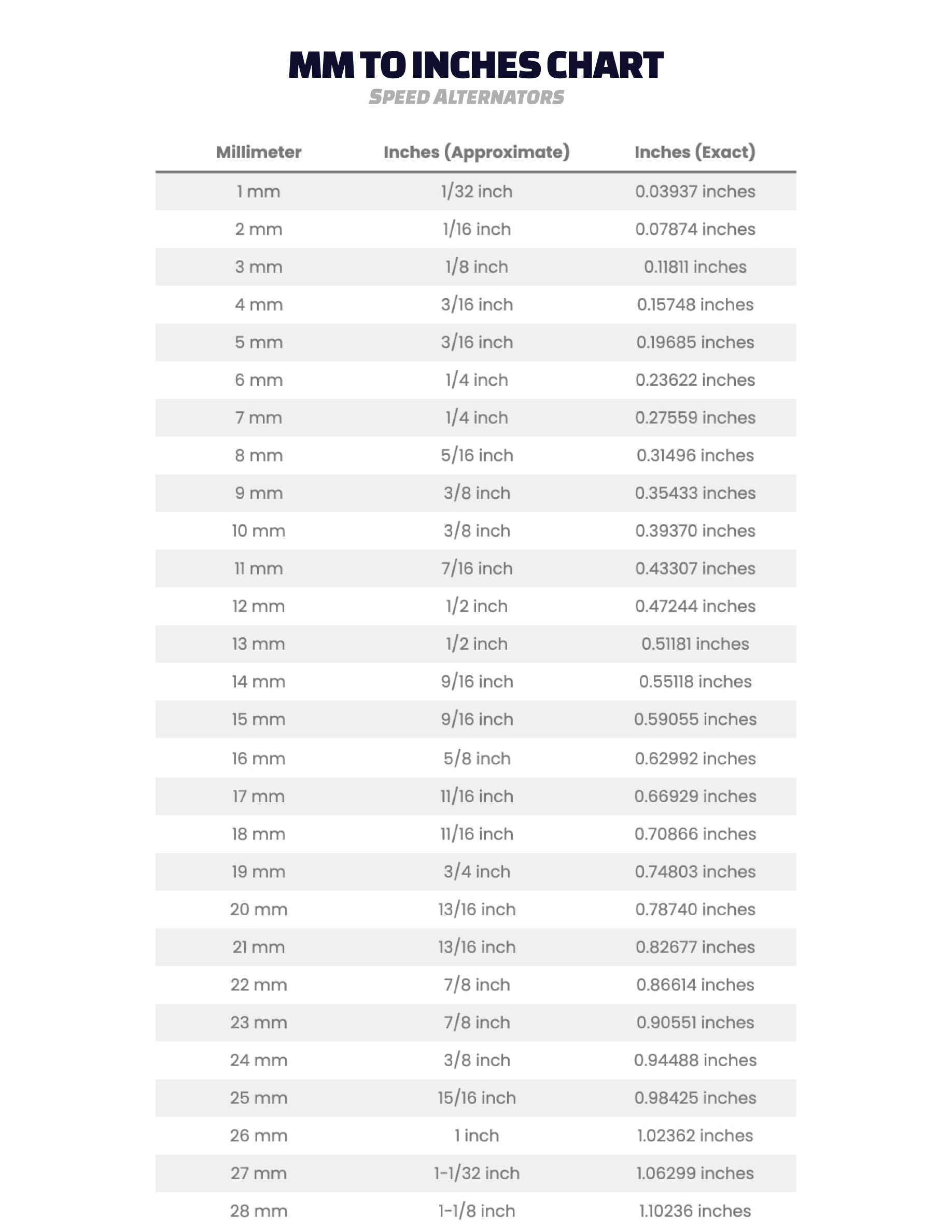

Mathematically, 2mm is exactly 0.0787402 inches.

🔗 Read more: Whole Foods Mountain View CA: Why This Store Is Different From Your Usual Grocery Run

Most people just round that to 5/64 of an inch. But honestly, even that doesn't help much if you can't visualize it. If you're looking for a quick real-world comparison, 2mm is roughly the thickness of two credit cards stacked on top of each other. Or, if you’re a fan of loose change, it’s just a hair thicker than a standard US nickel, which officially sits at 1.95mm.

The Math Behind How Long Is 2mm in Inches

The world runs on the international yard and pound agreement of 1959. This is where the conversion factor of 25.4mm per inch comes from. It’s not an approximation; it’s the legal definition. So, to find out how long is 2mm in inches, you take 2 and divide it by 25.4.

$$2 / 25.4 = 0.078740157...$$

In a machine shop, you'd call this "seventy-eight thou" (0.078"). In a woodshop, you’d probably just call it a "strong sixteenth" or a "weak five-sixty-fourths." Wood expands and contracts so much with humidity that worrying about the fourth decimal place of a millimeter is usually a waste of time. However, if you’re working with 3D printers or CNC machines, that decimal matters a lot.

The struggle with the imperial system is that we love fractions. But there isn’t a "perfect" fraction for 2mm.

- 1/16 inch is 1.5875mm (Too small).

- 5/64 inch is 1.9844mm (Extremely close, only off by about 0.015mm).

- 3/32 inch is 2.3813mm (Too big).

For almost every practical application—building a birdhouse, measuring a leather strap, or checking the thickness of a laptop—5/64" is your best bet.

Why This Specific Measurement Is a Headache for DIYers

Let’s talk about the "tolerance stack-up." This is a term engineers like to throw around when small errors start adding up to a big disaster.

If you're off by just 0.1mm on a single cut, you might not notice. But if you’re building a cabinet with twenty different joints and you’re "close enough" on every single one, the whole thing will be crooked. This is why understanding how long is 2mm in inches is vital when you're switching between tool sets.

I’ve seen people try to use a 2mm drill bit when the instructions called for a 5/64 inch bit. While 5/64" is 1.98mm, that tiny 0.02mm difference can be enough to make a screw strip the wood or sit too loosely in a metal pilot hole. In jewelry making, 2mm is a standard size for small gemstones or the width of a dainty wedding band. If you buy a 2mm stone and have a setting cut for exactly 0.07 inches, it’s not going to fit.

Real World Examples: Seeing 2mm in the Wild

Most of us don't walk around with a micrometer in our pockets. We need mental shortcuts.

Think about a standard mechanical pencil lead. The thick ones are 0.7mm or 0.9mm. Stack two of those 0.9mm leads together, and you're almost at 2mm.

Or consider your smartphone screen protector. A high-quality tempered glass protector is usually about 0.3mm to 0.5mm thick. You’d need to stack four or five of them to reach the 2mm mark.

In the world of medical devices, 2mm is a common diameter for catheters or small surgical pins. In that context, "close enough" isn't a phrase anyone wants to hear. Precision is everything. Even in something as mundane as pasta, the difference between a 1.5mm linguine and a 2mm spaghetti completely changes the "mouthfeel" and how much sauce the noodle carries.

The Tool Dilemma: Metric vs. Imperial

If you are constantly asking how long is 2mm in inches, you might be using the wrong tools for the job.

Most tape measures sold in the US have "inch" markings on the top and "centimeter" markings on the bottom. But here's the kicker: the lines on the metric side are usually much thinner and more precise.

When you look at a metric ruler, the tiny ticks are millimeters. 2mm is just two of those ticks. On the imperial side, the smallest mark is usually 1/16". Since 2mm is roughly 1.26 times larger than 1/16", it sits in that awkward "no-man's land" between the lines.

If you are working on a project designed in Europe or Asia, stay in metric. Don't convert. Converting is where the ghosts in the machine live. If a blueprint says 2mm, go buy a metric ruler. It’ll save you a headache and a trip back to the hardware store.

Common Items That Measure Exactly 2mm

- The thickness of a standard SD card.

- A heavy-duty guitar pick (often used by bass players or jazz guitarists).

- The wire diameter of a large paperclip.

- A 12-gauge piercing needle (Technically 2.05mm, but used interchangeably).

Why 2mm Matters in Modern Technology

We are living in an era of "thinness." Smartphone manufacturers fight over fractions of a millimeter. When a company says their new laptop is 2mm thinner than the previous model, it sounds like nothing. But in the palm of your hand, that 0.078-inch difference is the difference between "bulky" and "sleek."

In 3D printing, 2mm is actually a massive distance. Most "fine" 3D prints have layer heights of 0.1mm or 0.2mm. A 2mm wall thickness in a 3D-printed part is considered quite sturdy. If you mess up your unit conversion in your slicing software (like Cura or PrusaSlicer) and accidentally set a wall to 2 inches instead of 2mm, you're going to waste a whole spool of filament on a part that looks like a brick.

How to Measure 2mm Without a Ruler

Sometimes you're at a flea market or a garage sale and you need to know if a bolt or a wire is roughly 2mm. You don't have a ruler. What do you do?

👉 See also: What’s Actually Happening with Golden Triangle Mall Stores Right Now

Grab a nickel. As mentioned earlier, a US nickel is 1.95mm thick. It is the gold standard for "the 2mm eyeballing test." If the object is the same thickness as the nickel's edge, it's 2mm.

If you happen to have a spaghetti noodle—specifically #5 spaghetti—it is usually right around 2mm in diameter. Not that you'd carry a single strand of dry pasta for measurement purposes, but hey, stranger things have happened in a kitchen remodel.

Misconceptions About the 2mm Conversion

The biggest mistake people make is thinking that 0.2 inches is the same as 2mm. It's not. Not even close.

0.2 inches is about 5mm.

That’s more than double the size. This usually happens because our brains want to move the decimal point in a simple way. But because the conversion factor is 25.4, the math is never that clean.

Another misconception is that you can use a 2mm wrench on a 5/64" bolt. You technically can, because 2mm is slightly larger than 5/64" (1.98mm). The 2mm wrench will fit over the bolt, but it will be slightly "slloppy." If that bolt is stuck or rusted, using the 2mm wrench will almost certainly round off the corners of the bolt head, leaving you with a nightmare scenario and a pair of locking pliers in your future.

Moving Forward With Your Measurements

To get the best results in your project, stop trying to find the "inch" equivalent of metric measurements. The world is increasingly metric, even in the United States.

Invest in a pair of digital calipers. You can find a decent pair for under twenty bucks. They allow you to toggle between millimeters and inches with a single button. No more math. No more guessing if you're looking at 5/64 or 3/32. Just pure, digital certainty.

If you are stuck using a standard ruler, just remember the nickel. If it’s about the thickness of a nickel, it’s 2mm. If it’s significantly thicker or thinner, you’re looking at a different measurement entirely.

💡 You might also like: How to Hurt a Narcissist: Why Your Silence Is the Only Weapon That Actually Works

The next time you’re asked how long is 2mm in inches, you can confidently say it’s 0.078", but for the sake of your sanity, just call it a "nickel's edge" and move on with your day.

Actionable Next Steps

- Check your toolkit: If you only have imperial wrenches and bits, buy a small "metric expansion" set. It's cheaper than replacing stripped bolts.

- Calibration check: Take a US nickel and measure it with your current ruler or calipers. If it doesn't read 1.95mm or roughly 0.077 inches, your measuring tool is off.

- Download a conversion app: Keep a unit converter on your phone for those moments at the hardware store when your brain freezes on the 25.4 math.

- Label your bins: If you have jars of random screws, take five minutes to separate the metric from the imperial. You'll thank yourself during your next late-night repair.