You’ve probably been there. You’re halfway through vacuuming the living room, and suddenly, that reassuring hum of the brush bar turns into a pathetic, high-pitched whine or just stops entirely. It’s annoying. Honestly, it’s one of those "I’ll do it later" chores that ends up sitting in the closet for three months. But if you own a Dyson DC33, you’re dealing with a machine that is basically the tank of the vacuum world. It’s old, it’s heavy, and it’s surprisingly repairable.

The problem? Dyson DC33 belt removal isn’t exactly a "one-click" situation. Unlike modern cordless stick vacs that just pop apart, the DC33 uses a clutch system. This means there isn't just one belt—there are actually two hidden inside a plastic housing. If your brush isn't spinning, you're likely going to have to dig deep.

Why the DC33 Belt is Such a Pain

Most people think they can just flip the vacuum over, unscrew a plate, and swap a rubber band. Nope. Not on this model. The DC33 is a "clutched" machine, designed so you can turn the brush bar off for hard floors and on for carpets. This mechanism is great for versatility but a nightmare for DIY repairs if you don't know the trick.

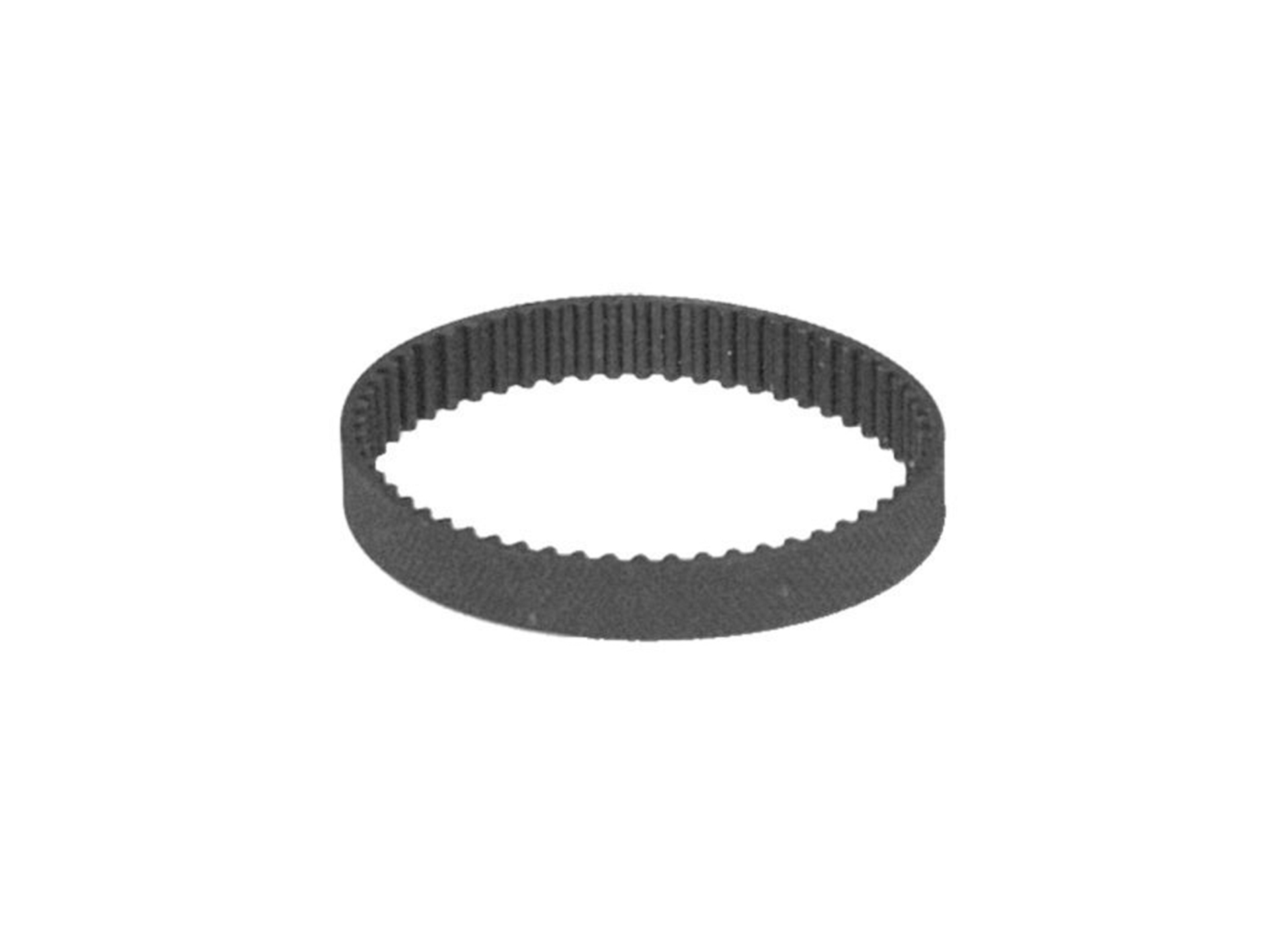

The belt doesn't just sit on the motor. It connects the motor to a clutch, and then another belt connects that clutch to the brush bar. If the brush isn't spinning, 90% of the time it’s the outer belt (the one you can see). The other 10%? The internal belt or the clutch itself has literally melted. I’ve seen clutches that look like they’ve been through a campfire because a stray sock jammed the brush and the friction just cooked the plastic.

📖 Related: Video of SpaceX Launch Today: What Actually Happened at Vandenberg

Getting Started: Tools and First Steps

Before you start hacking away, grab a few things. You’ll need a flat-head screwdriver (or a large coin), a T15 Torx screwdriver, and maybe a pair of pliers.

First, unplug the thing. Seriously.

Lay the vacuum on its back. You’ll see three plastic "screws" on the bottom soleplate. Give them a quarter-turn counter-clockwise. You can use a coin for this; it actually works better than a screwdriver sometimes. Once those are loose, the soleplate should just lift off. If it feels stuck, it’s probably just caked-on dust and hair acting like glue. Give it a firm wiggle.

The Actual Dyson DC33 Belt Removal Process

Now that the plate is off, you’re looking at the brush bar. This is where people get frustrated. The belt is under immense tension. It’s not like a loose fan belt on an old car; it’s tight.

1. Freeing the Brush Bar

Grab the right side of the brush bar (the side without the belt) and pull it toward you. You’ll have to angle it out. Once that end is free, you can slide the whole bar out of the belt loop. It’s going to be dirty. There’s going to be hair. Just deal with it now so you don't have to later.

2. Opening the Clutch Housing

To actually perform a full Dyson DC33 belt removal, you usually need to get into the clutch. There are three T15 Torx screws holding the clear/black cover in place. Two are easy to see. The third one? It’s a total "where is it?" moment. It’s hidden behind the U-bend pipe at the back. You’ll need to unclip the clear U-bend tube first to even see the screw head.

3. The Belt Lifter Trick

If you’re just trying to change the belt and not the whole clutch, you’ll realize quickly that the new belt is incredibly stiff. Pros use a "belt lifter" tool. It’s basically a metal hook that gives you leverage. If you don't have one, you can use two long screwdrivers to stretch the belt over the pulley, but be careful. If you slip, you’re going to bark your knuckles or, worse, crack the plastic housing.

📖 Related: Contact Center AI News: What Most People Get Wrong About Agentic AI

When to Give Up and Buy a New Clutch

Sometimes, you’ll get that cover off and realize the belt hasn't snapped—it’s just loose. Or maybe the internal belt (the one from the motor to the clutch) is toast.

Honestly? If the internal belt is gone, don't bother trying to replace just the belt. It is a miserable job that involves taking apart the actual clutch mechanism, which is full of springs and tiny ball bearings that love to fly across the room. Just buy a pre-assembled clutch. They usually cost about $25 to $35 and come with both belts already installed. It’s a "drop-in" fix that saves you three hours of swearing.

Common Mistakes to Avoid

Don't use a hammer. I know it sounds stupid, but people do it. They try to tap the motor spindle or force the clutch out with blunt force. The plastic on these older Dysons can get brittle over time. If you crack the main chassis, the vacuum is basically scrap metal.

Also, check your brush bar bearings. If the belt snapped, it might be because the bearings in the brush bar have seized up. If you put a brand new belt on a seized brush bar, you’ll smell burning rubber within sixty seconds, and you’ll be right back where you started. Spin the brush bar with your hand. It should spin freely for a few seconds. If it stops instantly or feels "crunchy," you need a new brush bar too.

Keeping it Running

Once you've managed the Dyson DC33 belt removal and got the new one on, do yourself a favor: clean the filters. A clogged filter makes the motor run hotter, which makes the whole machine vibrate more, which puts more stress on the clutch.

It’s all connected.

Actionable Next Steps

- Inspect the Belt: Flip the vacuum and look at the belt while the brush bar is still in. If it looks "hairy" or has cracks, replace it now before it snaps mid-clean.

- Test the Clutch: With the vacuum off, turn the carpet/floor knob. It should feel "clicky" and firm. If it’s mushy, the internal spring is likely gone.

- Order a T15 Torx: If you don't own one, you can't fix this vacuum. Period. Most hardware stores sell them for five bucks.

- Clear the U-Bend: Since you have to remove it anyway to get to the third screw, wash it out with warm soapy water. You’d be surprised how much suction you’re losing to a partial clog there.

Taking the time to do this yourself is worth it. These machines were built to last, and once you get past the learning curve of the clutch system, you can keep a DC33 running for another decade. Just remember: patience and the right screwdriver are your best friends here.