You’re merging onto the highway. You floor it. Instead of that familiar vroom-shift-vroom rhythm you’ve heard since you were a kid, the engine just… stays high. It screams at a single pitch like a vacuum cleaner on a mission. If you’ve experienced this, you’ve met a CVT.

CVT in a car stands for Continuously Variable Transmission. It’s a piece of engineering that some people absolutely loathe, while engineers generally adore it for its sheer efficiency. Most traditional automatics use a set of gears—first, second, third, and so on. A CVT doesn't have gears. Not in the traditional sense, anyway. It uses a system of pulleys and a high-strength belt to create an infinite number of gear ratios. It's basically the math nerd of the automotive world, constantly calculating the exact ratio needed to keep your engine in its "happy place."

How a CVT Actually Works Without Traditional Gears

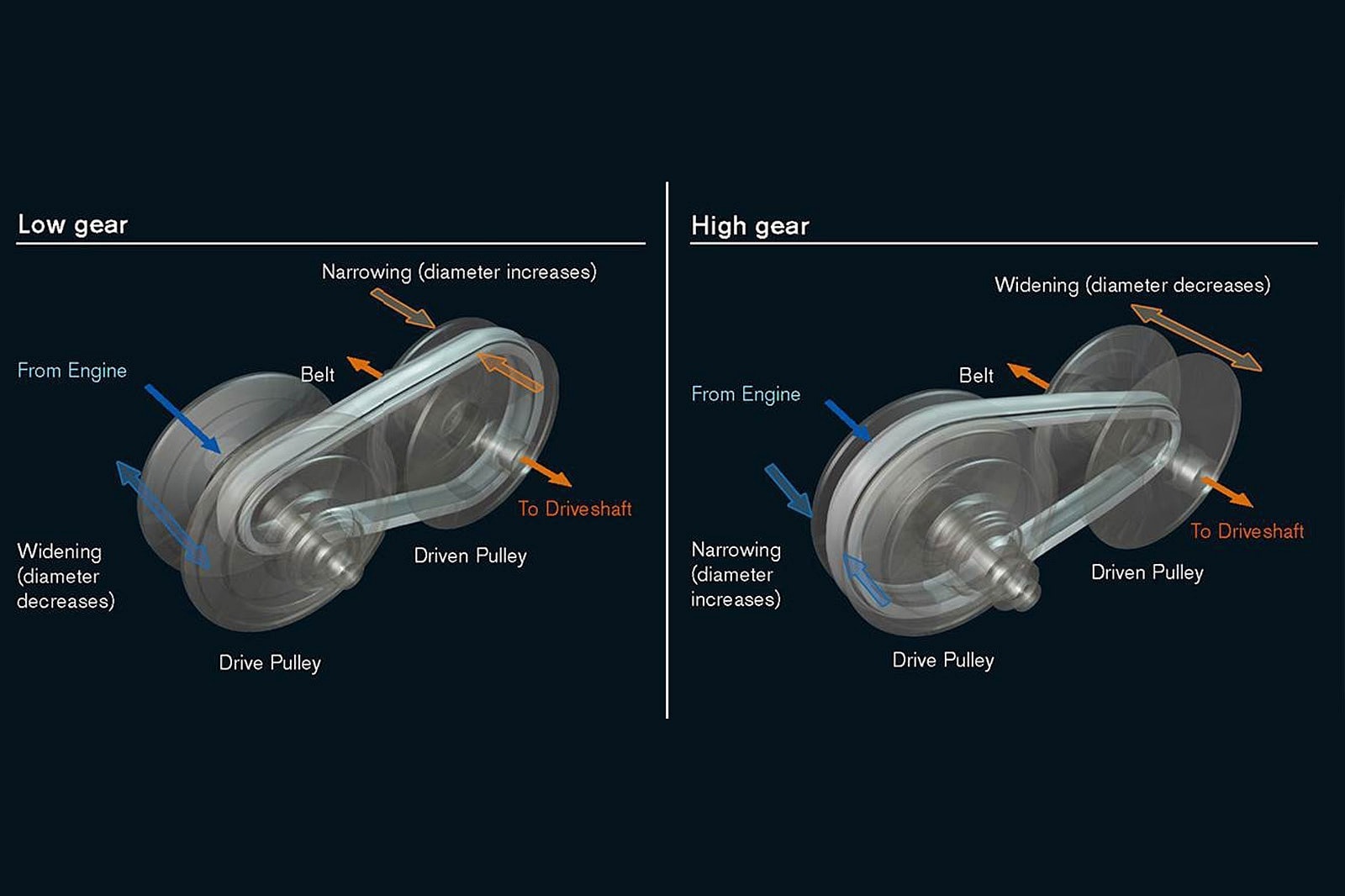

Forget everything you know about cogs interlocking. Imagine two cones facing each other, connected by a heavy-duty belt. When the cones move closer together or further apart, the belt moves higher or lower on the cone. This changes the diameter.

If the belt is riding on a small diameter at the input and a large diameter at the output, you’ve got a low gear for starting from a stop. As you speed up, the pulleys adjust seamlessly. This is why it’s called "continuously variable." There are no steps. No gaps. Just a fluid slide from low to high. Brands like Nissan and Subaru have bet their entire reputations on this tech. Nissan’s "Xtronic" system is perhaps the most famous—or infamous, depending on who you ask—example of this in the wild.

Honestly, the feeling is weird at first. You expect the car to "kick" when it shifts. It won't. It just climbs in speed while the RPM needle stays eerily still.

📖 Related: Yahoo Mail Down Today: Why Your Inbox Is Stuck and How to Fix It

Why Manufacturers Are Obsessed With Them

Money and air. That’s what it boils down to. Government regulations on fuel economy (like the CAFE standards in the US) are getting stricter every single year. A traditional 6-speed automatic is limited. If the engine is most efficient at 2,200 RPM, but a 6-speed gear set only lets it sit at 1,900 or 2,500 at a certain speed, you’re wasting gas.

A CVT in a car solves this by finding 2,200 RPM and staying there. It’s why a Honda Civic or a Toyota Corolla can pull off such impressive MPG numbers despite not being hybrids. They are lightweight, have fewer moving parts than a complex 10-speed planetary automatic, and they keep the engine in its peak power band longer.

The "Rubber Band" Effect and Other Gripes

If CVTs are so efficient, why do car enthusiasts complain about them constantly? It’s the "rubber band effect." Because the transmission is adjusting pulleys rather than swapping solid gears, there’s often a slight delay between you hitting the gas and the car actually moving with urgency. It feels disconnected.

Then there’s the noise. Early CVTs, especially those in the mid-2000s, were loud. They droned. To fix this, many modern manufacturers like Toyota and Honda have programmed "fake" shift points into the software. The car will literally pretend to shift—dropping the RPMs momentarily—just to make the driver feel more comfortable. It’s a psychological trick. We are so conditioned to hear gear changes that the absence of them feels like something is broken.

Reliability and the 100,000-Mile Question

Let's talk about the elephant in the room: Nissan. About a decade ago, Nissan’s Jatco-sourced CVTs became legendary for failing early. This gave the entire technology a bad name. People started associating CVT in a car with "expensive paperweight."

🔗 Read more: Why Your TV Guide LG TV Experience Feels Clunky and How to Fix It

However, things have changed. A modern CVT from 2024 or 2025 is a far cry from the ones found in a 2013 Altima. Toyota’s "Direct Shift" CVT even uses a physical "launch gear" to handle the initial stress of taking off from a stop, which is where most CVTs used to struggle and wear out. Once the car is moving, it hands the work over to the belt and pulleys. It’s a brilliant compromise.

Is a CVT Right For Your Driving Style?

If you are a "car person" who wants to feel the mechanical engagement of a drive, you’ll probably hate it. You’ll miss the crispness of a Dual-Clutch Transmission (DCT) or the reliability of a heavy-duty ZF 8-speed automatic.

But if you’re a commuter? If you just want to get from point A to point B with the least amount of gas used and the smoothest ride possible? The CVT is actually superior. It’s smoother in stop-and-go traffic because there’s no gear hunting. There’s no lurching when the car can’t decide if it should be in second or third gear while you’re crawling through a school zone.

Maintenance That Most People Ignore

You cannot treat a CVT like a regular transmission. The fluid is different. It’s not just a lubricant; it’s a friction modifier that helps the belt grip the pulleys. If that belt slips, the transmission is toast.

- Check the fluid every 30,000 miles. Even if the manual says "lifetime fluid," talk to a trusted mechanic. "Lifetime" usually means the lifetime of the warranty, not the lifetime of the car.

- Avoid heavy towing. Unless the car is specifically rated for it (like some versions of the Subaru Outback), CVTs generally don't handle the heat of towing very well.

- Watch for "limp mode." If the transmission overheats, the car will drastically cut power to protect itself. This is a sign your fluid is spent or the cooling system is failing.

Real-World Examples of Who is Doing it Right

Subaru’s Lineartronic is generally well-regarded because they’ve used a chain instead of a belt in many models, which is more durable. Toyota's K120 "Direct Shift" is the current gold standard for reliability because it removes the high-stress "launch" phase from the CVT belt entirely.

On the flip side, many budget subcompacts still use cheaper, belt-driven CVTs that can feel sluggish. When you're test-driving, pay attention to how the car reacts when you need to quickly change lanes. If it feels like the engine is revving but you aren't going anywhere—that's the "drone" you want to avoid.

Actionable Steps for Car Buyers

If you are looking at a car with a CVT, don't just take the salesperson's word that it's "the same as an automatic." It isn't.

- Test drive on a hill. See how the transmission handles holding the car and accelerating from a stop on an incline. This is where weak CVTs show their flaws.

- Research the specific model year. Look at sites like CarComplaints.com. A 2015 Nissan Rogue has a very different reputation than a 2023 model.

- Listen for whining. A healthy CVT should be relatively quiet. If you hear a high-pitched whine that gets louder as you accelerate, the bearings or the belt might be on their way out.

- Factor in fluid changes. Budget about $200–$400 every few years for a proper transmission flush. It is significantly cheaper than a $5,000 replacement.

The reality of the CVT in a car is that it’s a tool designed for a specific purpose: efficiency. It isn't built for the racetrack, and it isn't built for heavy rock crawling. It's built for the suburban sprawl and the 40-mile highway commute. As long as you understand those limitations and keep up with the fluid changes, there's no reason a modern CVT can't last as long as the rest of the car.