Precision matters. It really does. If you’re holding a caliper right now and trying to figure out why your 3D print won't snap together or why that specific screw feels "mushy" in its housing, you're likely staring at a fraction of an inch that seems insignificant. It isn't. When we talk about 0.06 inch in mm, we are looking at exactly 1.524 mm.

That’s it.

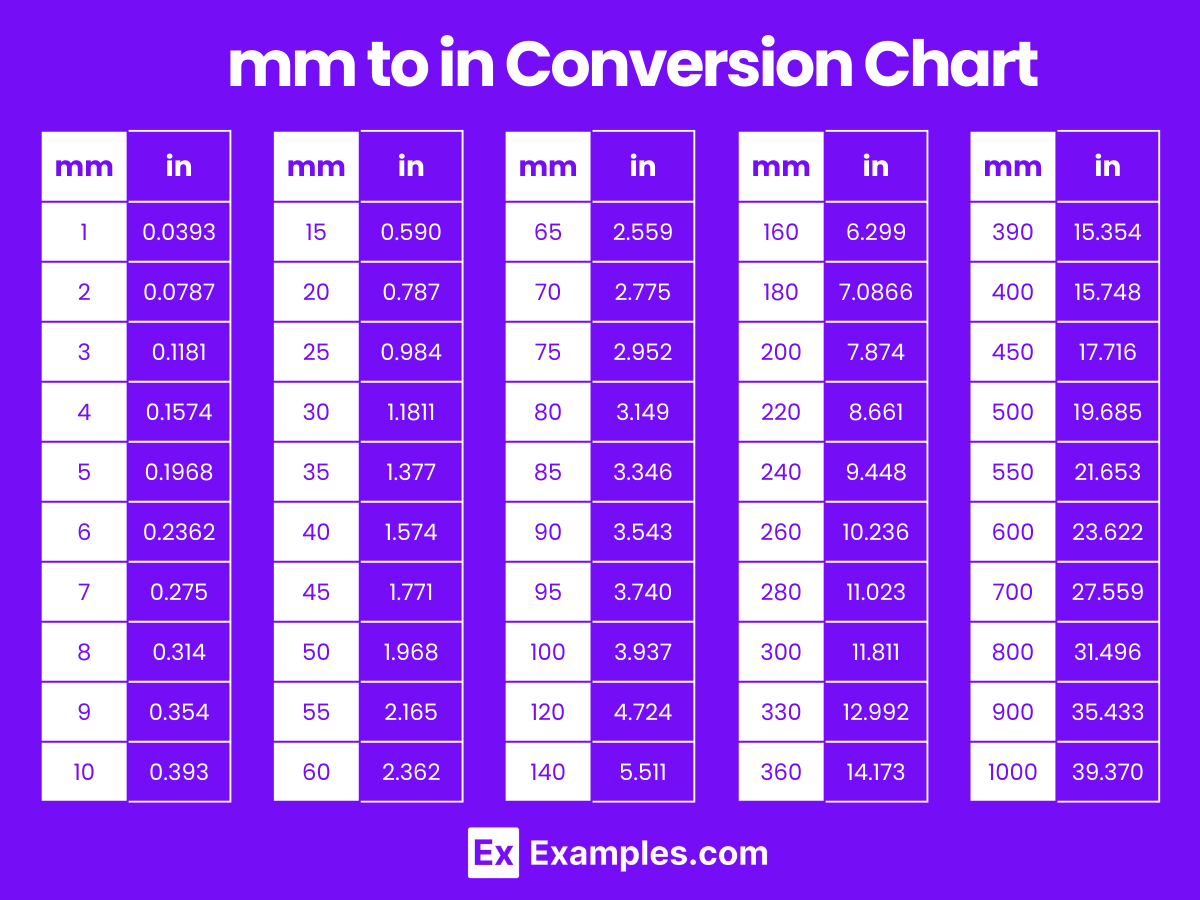

The math is simple, but the implications in engineering, jewelry making, and PCB design are massive. You take the base conversion factor—which is $1 \text{ inch} = 25.4 \text{ mm}$—and multiply it.

$0.06 \times 25.4 = 1.524$

Most people just round it. They say "one and a half mils" or just "1.5 mil." But if you are working in a machine shop or designing a medical device, that extra 0.024 mm is the difference between a "press fit" and a "loose fit." I've seen entire production runs of aluminum spacers scrapped because someone thought "close enough" was fine for a conversion. It rarely is.

Why 0.06 inch in mm is a standard you see everywhere

You might wonder why this specific number keeps popping up on your spec sheets. It’s not random. In the world of sheet metal and wire gauges, 0.06 inches is roughly equivalent to 16-gauge steel. If you’ve ever bought a high-quality stainless steel sink or a heavy-duty computer case, you’re likely touching metal that is 1.524 mm thick.

It’s a sweet spot.

It’s thick enough to be structurally sound and resist bending under hand pressure, yet thin enough to be stamped and formed without needing a 500-ton hydraulic press. If you go thinner, to say 0.04 inches, things start to feel "tinny" and cheap. Go thicker, and your shipping costs skyrocket because of the weight.

The PCB and electronics connection

In the electronics world, 0.06 inches (or 1.524 mm) is the "classic" thickness for a standard printed circuit board (PCB). If you pull apart an old radio or a modern desktop motherboard, that rigid green fiberglass slab is almost certainly 0.062 inches thick. Okay, I’m being precise here—the industry standard is 1.6 mm, which is the metric "round up" of the old 1/16th inch (0.0625") standard.

👉 See also: Why the Facebook Picture Loading Screen Gets Stuck and How to Fix It

Why does this matter?

Because if you’re designing a custom enclosure or a 3D-printed bracket to hold a circuit board, and you calculate your slot for exactly 0.06 inch in mm, the board won't fit. You'll be off by that tiny fraction. You need to account for the solder mask, the copper weight, and the manufacturing tolerances of the FR4 material itself.

Real-world precision and the "Human Hair" metric

To give you some perspective, a human hair is usually around 0.05 mm to 0.10 mm thick. So, when we talk about the difference between 0.06 inches (1.524 mm) and a standard 1.5 mm measurement, we are talking about roughly half the width of a human hair.

Does that matter to you?

If you're building a bookshelf? No.

If you're shimming a valve in a high-performance engine? Absolutely.

I remember talking to a watchmaker in Neuchâtel who joked that Americans think in "chunks" while the Swiss think in "shadows." He was referring to how imperial measurements often get rounded awkwardly when moved into metric CNC environments. If your CAD software is set to imperial but your milling machine is expecting metric inputs, and you don't use the exact 1.524 mm conversion, you’ll end up with "tool chatter" or parts that simply don't mate.

Common items that measure approximately 1.5 mm

- A standard US penny is about 1.52 mm thick.

- A 16-gauge steel plate.

- The wire diameter of a heavy-duty paperclip.

- Standard 5-ply aircraft grade plywood (often slightly thinner, but close).

- The thickness of a high-quality guitar pick (extra heavy).

The math behind the conversion (and why it's weird)

The 25.4 constant is actually an international agreement. Before 1959, the US inch and the UK inch were slightly different. Imagine that headache. The "International Yard and Pound Agreement" finally fixed the inch at exactly 25.4 mm. No more "almost." No more drifting decimals.

When you convert 0.06 inch in mm, you aren't just doing math; you're participating in a global standard of precision that took centuries to iron out.

If you’re using a calculator, just remember the 25.4 rule.

If you’re using your head, think: "One and a half, plus a tiny bit more."

Misunderstandings in the hardware store

Kinda funny thing happens at the hardware store. You ask for a 1.5 mm drill bit, but the closest "inch" equivalent is 1/16 of an inch. But 1/16 is 0.0625 inches. That’s 1.5875 mm.

If you use a 1/16 drill bit for a hole that specifically requires a 0.06 inch (1.524 mm) pin, your pin is going to wobble. It’s going to fall out. You’ll end up using Loctite or superglue to fix a problem that started with a rounding error. Always check if your fasteners are metric or SAE before you start drilling. Honestly, it saves so much frustration.

How to measure 0.06 inches accurately

Don't use a ruler. Just don't. The lines on a standard plastic or wood ruler are usually 0.5 mm thick themselves. You can't see the difference between 1.5 mm and 1.524 mm with the naked eye against a wooden stick.

- Digital Calipers: This is the gold standard. Set it to "mm" and look for 1.52. If you set it to "inch," look for 0.060.

- Micrometers: If you're working in a machine shop, a micrometer will give you the 1.524 precisely.

- Feeler Gauges: These are little metal strips of known thicknesses. Mechanics use them to set spark plug gaps. You can stack them to hit exactly 0.06 inches.

Practical Steps for your project

If you are currently staring at a design file or a piece of hardware and need to move forward with 0.06 inch in mm, follow these steps to ensure you don't mess up the tolerances.

First, identify your tolerance level. If you are working in woodworking, just use 1.5 mm. Your wood will expand and contract more than 0.024 mm just based on the humidity in your garage anyway. It's pointless to be more precise than the material allows.

Second, if you're 3D printing, check your "Initial Layer Height" or "Horizontal Expansion" settings. Most consumer 3D printers have a nozzle diameter of 0.4 mm. This means your wall thickness of 1.524 mm is actually about four "lines" of plastic. Most slicers will round this to 1.5 mm or 1.6 mm depending on your wall line count settings.

Third, when ordering raw materials like sheet metal or plastic shim stock, always specify the decimal. Don't just say "about a sixteenth." Say "zero-six-zero inch" or "one-point-five-two millimeter." Pros will know exactly what you mean.

Finally, if you are converting an entire blueprint from imperial to metric, do not convert each measurement individually and round them. This leads to "tolerance stack-up." Add up your total dimensions in the original unit first, then convert the final sum to metric. This keeps your errors from multiplying across the length of the project.

Precision is a habit. Whether you're a hobbyist or a professional, treating 0.06 inches as 1.524 mm is the first step toward building things that actually fit together the first time. Keep your calipers calibrated and your conversion constants exact.