You're standing in the hardware aisle. Or maybe you’re looking at a bicycle tire. Perhaps you’ve got a 3D printer humming in the background and the file is in metric, but your brain—your stubborn, North American or UK-influenced brain—only thinks in fractions of an inch. You need to convert mm to inches right now, and you need it to be accurate.

It happens to everyone.

The problem isn't just the math. It's the precision. Most people grab a calculator, type in their number, and end up with a string of decimals long enough to reach the moon. That doesn’t help when you’re trying to find a 1/4-inch bolt or a 10mm socket. In reality, the bridge between the International System of Units (SI) and the US Customary system is paved with rounding errors. If you miss by a hair, the engine won't start, the shelf won't hang straight, or the medical device—heaven forbid—won't fit.

The Magic Number You Actually Need

Forget the long decimals for a second. Let's get down to the bone. One inch is exactly 25.4 millimeters.

Not "roughly." Not "around." Since the International Yard and Pound Agreement of 1959, 25.4 is the hard, legal standard. If you want to convert mm to inches, you divide your millimeter figure by 25.4. That’s the gospel.

$1 \text{ inch} = 25.4 \text{ mm}$

$x \text{ inches} = \frac{y \text{ mm}}{25.4}$

But honestly? Doing long division in your head while holding a greasy wrench is a nightmare. Most mechanics and woodworkers use "mental shortcuts" that get them close enough to avoid a headache. For example, 25mm is almost exactly an inch. It's actually about 0.98 inches. If you can remember that 25 is your "near-inch" marker, you can eyeball most things in a pinch. If a bolt is 50mm, you know it's roughly two inches.

It’s simple until it isn’t.

Why Converting mm to Inches is a Constant Battle

Precision is a fickle friend. In the world of machining, a "thou" (one-thousandth of an inch) is the difference between a masterpiece and scrap metal. If you're 3D printing, 0.1mm is the thickness of a sheet of paper. When you convert mm to inches for high-stakes projects, you can't just round up because you feel like it.

Think about the "Great Math Error" of the Mars Climate Orbiter in 1999. NASA lost a $125 million spacecraft because one team used metric units while another used English units. One team was thinking in Newtons, the other in pound-force. While that's force and not length, the principle remains: units matter. If the smartest rocket scientists on the planet can mess up a conversion, you and I definitely can while trying to install IKEA furniture.

Most people struggle because metric is base-10. It's logical. It’s clean. You move a decimal point, and suddenly a centimeter becomes a meter. But inches? Inches are a mess of fractions. 1/2, 1/4, 1/8, 1/16, 1/32, 1/64. Our brains aren't wired to jump from "12.7mm" to "half an inch" instantly. We have to translate a decimal system into a fractional system.

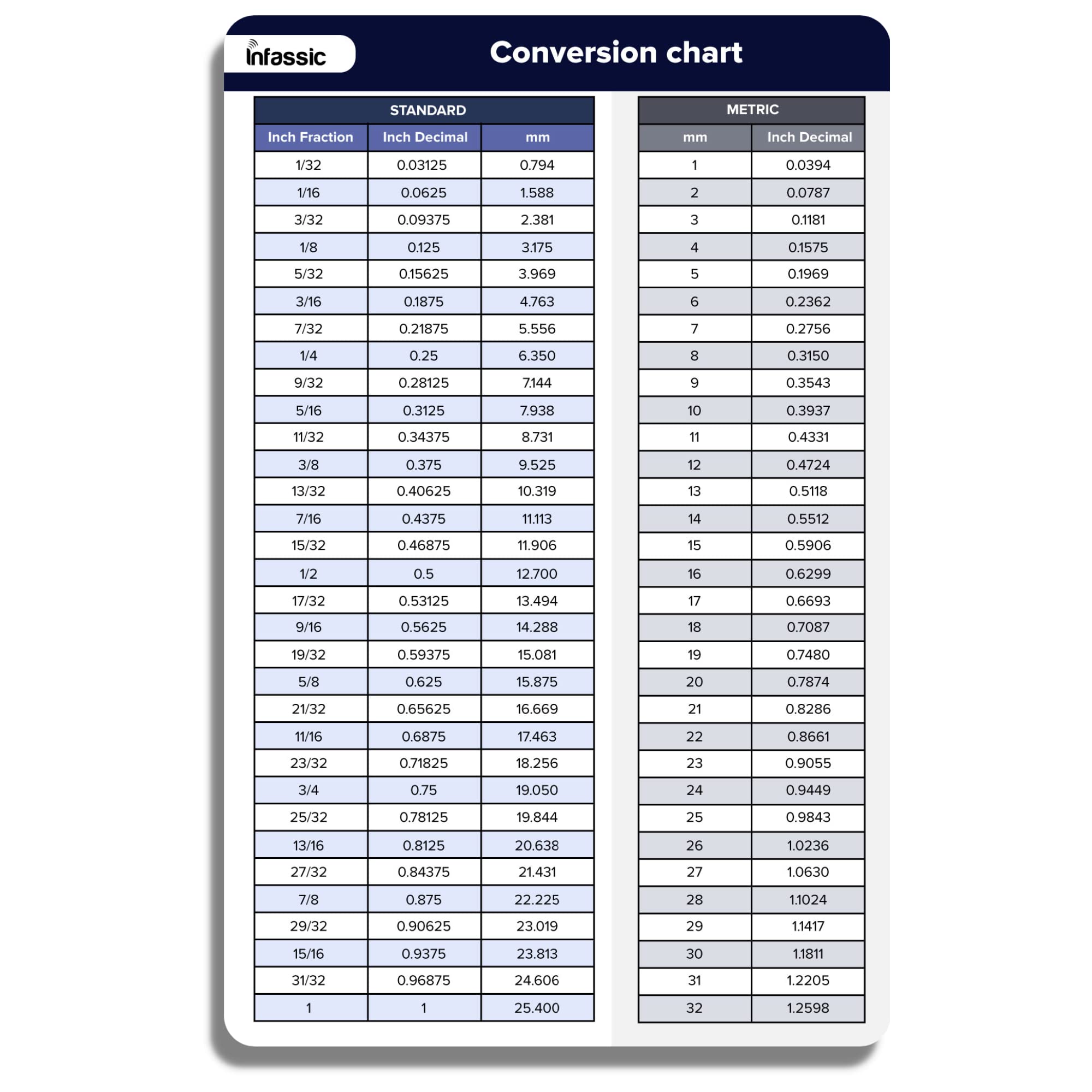

The Table of Truth (Metric to Fractional Inch)

Since I promised no perfect, robotic tables, let's just talk through the common ones you'll actually see in the wild.

If you see 2mm, that’s about 5/64 of an inch. Tiny.

6mm is the "almost 1/4 inch" size. Actually, 1/4 inch is exactly 6.35mm. If you try to force a 6mm Allen wrench into a 1/4 inch screw, you’re going to strip that screw. I've done it. It’s a bad Saturday afternoon.

Moving up, 10mm is roughly 13/32 inches. But most people just call 10mm the "most lost socket in the world."

13mm is your 1/2 inch equivalent. It's actually 12.7mm. Close? Yes. Identical? No.

19mm is nearly 3/4 of an inch (which is 19.05mm).

25.4mm is your 1 inch.

✨ Don't miss: The Forbidden Meaning in Hindi: Why Context Changes Everything

When you’re at the gym, you might see 25kg plates. That’s weight, but the dimensions of those plates often follow these same conversion headaches. A 50mm Olympic bar sleeve is about 1.96 inches. Close enough for a weight plate, but not for a piston ring.

The Pitfalls of Rounding Too Early

Here is what most people get wrong. They round the millimeter number before they do the division.

Don't do that.

If you have 15.875mm and you round it to 16mm before dividing by 25.4, you’ve already introduced an error. In the world of engineering, this is "stacking tolerances." If you have ten parts and each one is rounded slightly off, the final assembly will be a disaster.

Always keep as many decimals as possible until the very last step. If your calculator gives you 0.625, that’s a beautiful 5/8 of an inch. If it gives you 0.629, you’re looking at something just slightly larger than 5/8, and you might need to adjust your fit.

Real-World Scenarios Where This Matters

1. Photography and Optics

Lens filters are almost always in millimeters. 58mm, 77mm, 82mm. But tripod mounts? Those are almost always 1/4 inch or 3/8 inch. If you’re building a custom rig, you’re constantly jumping between these two worlds.

2. Jewelry

If you're buying a ring or a necklace chain, millimeters are the standard for thickness. A 2mm chain is delicate; a 6mm chain is chunky. If you’re used to inches, visualizing a 4mm wedding band is tough. Just remember: a US nickel is about 2mm thick. Stack two nickels, and you've got a 4mm band. Easy.

3. Graphic Design and Printing

Paper sizes like A4 are metric (210 x 297mm). But margins in software like InDesign are often set to inches in the US. If you don't convert mm to inches correctly, your bleed lines will be off, and the printer will cut off your text.

Digital Tools vs. Mental Math

We live in 2026. You probably have a phone that can do this for you. You can literally whisper "How many inches is 45mm" to your wrist and get an answer. But what if you’re out of service? What if you’re in a workshop where you don't want to touch your clean phone with greasy fingers?

Learn the "Divide by 25" rule for a quick estimate.

100mm? Divided by 25 is 4. So it’s a bit less than 4 inches (it’s actually 3.93).

75mm? Divided by 25 is 3. So it’s a bit less than 3 inches (it’s actually 2.95).

This mental shortcut works because 25 is a nice, round number that’s very close to 25.4. It gets you within 1.6% of the true value. For most household tasks, 1.6% is totally fine. For aerospace engineering? Stick to the 25.4.

Moving Beyond the Basics

Sometimes you need to go the other way. If you have an inch measurement and need millimeters, you multiply.

3 inches? $3 \times 25.4 = 76.2\text{mm}$.

A 1/2 inch pipe? $0.5 \times 25.4 = 12.7\text{mm}$.

It’s just a mirror image of the division. But again, keep an eye on those fractions. Converting 5/16 of an inch to mm requires you to first turn 5/16 into a decimal (0.3125) and then multiply.

Actionable Steps for Perfect Conversions

If you want to stop guessing and start measuring like a pro, follow these steps:

- Buy a dual-scale ruler. It sounds obvious, but having both scales physically next to each other helps your brain build a visual map of the conversion. You’ll start to "see" that 10mm is just under the 1/2 inch mark.

- Use the 25.4 constant. Never use 25 or 26 for final measurements. Bookmark a reliable conversion tool or write "25.4" on a piece of masking tape and stick it to your workbench.

- Identify your "tolerance." Ask yourself: "How much does this matter?" If you’re measuring a rug, a millimeter is nothing. If you're measuring a spark plug gap, it's everything.

- Convert to decimals first. If you're starting with a fraction like 3/8, divide 3 by 8 to get 0.375, then multiply by 25.4 to get your millimeter count (9.525mm).

- Check for "nominal" sizes. In plumbing and construction, a "2x4" isn't actually 2 inches by 4 inches. Similarly, a 1/2 inch pipe might not be exactly 12.7mm on the outside. Always measure the actual object rather than relying on the label.

By keeping the 25.4 ratio in your back pocket and understanding when to use mental shortcuts versus hard math, you’ll navigate any project without the typical metric-to-imperial frustration. Accuracy isn't just about the numbers; it's about knowing which tool to use for the job at hand.