You’ve seen them. Those thin, elegant lines fanning out from a central tower, holding up thousands of tons of concrete and steel like a high-tech harp. They look delicate. Honestly, from a distance, they look like they might just snap if a heavy truck drives over. But cable stayed bridge cables are arguably some of the most over-engineered components in modern civilization. We’re talking about high-tensile steel that can withstand forces so immense it defies common sense.

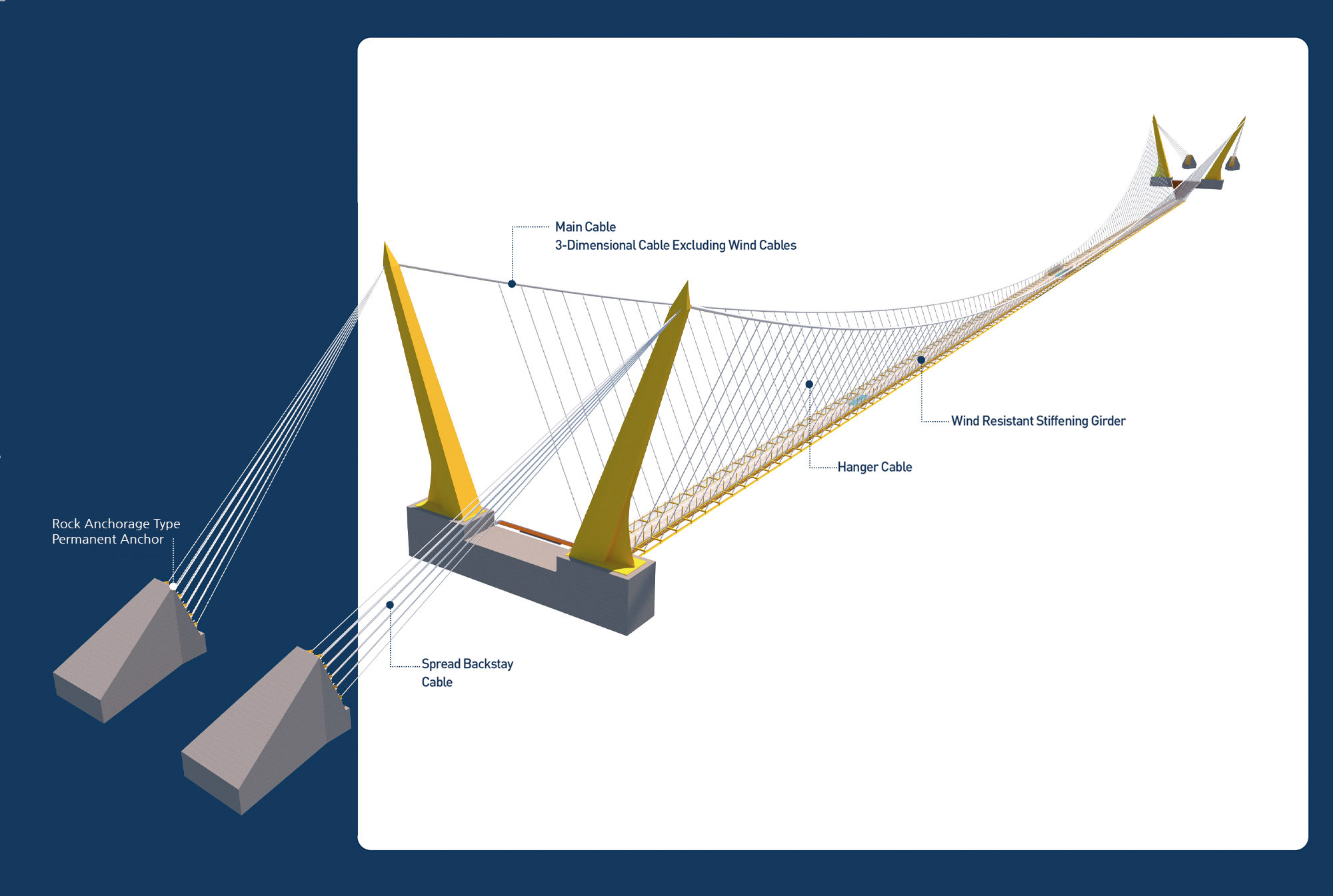

It’s easy to confuse these with suspension bridges. Don't. In a suspension bridge, the main cables hang in a curve (a catenary) and support the deck via vertical suspenders. In a cable-stayed system, the cables go directly from the tower to the deck. This creates a much stiffer structure. It’s a direct connection. This matters because it changes how the bridge breathes, moves, and—most importantly—how it fails.

The Anatomy of a Modern Stay Cable

A "cable" is a bit of a misnomer. It’s actually a complex assembly. Most modern bridges, like the Millau Viaduct in France or the Gordie Howe International Bridge, use what we call "seven-wire strands."

Basically, you take six high-strength steel wires and wrap them around a seventh central wire. Then, you take dozens or even hundreds of these strands and bundle them together into a single stay. Why seven? It’s the most efficient way to pack circles together tightly. This bundle is then encased in a high-density polyethylene (HDPE) pipe. This isn't just for looks. The pipe is the first line of defense against the bridge’s greatest enemy: corrosion.

Engineers like Michel Virlogeux, who designed the Millau Viaduct, have spent decades obsessing over how to keep moisture away from the steel. If water gets in, the bridge starts dying from the inside out. That’s why many cables are now filled with petroleum wax or have dry air circulated through them. It sounds like a lot of work for a big piece of metal, but when you’re dealing with the life of a billion-dollar asset, you don't take chances.

Materials That Push the Limit

The steel used isn't the stuff in your car. It’s cold-drawn, high-tensile carbon steel. It has a breaking strength that would make a regular construction beam look like a wet noodle. Specifically, we're looking at ASTM A416 grade steel in the US, which usually has a tensile strength of 270,000 psi (pounds per square inch).

Some people ask about carbon fiber. It’s light. It’s strong. It doesn't rust. Sounds perfect, right? Well, sort of. While projects like the Laroin Footbridge in France have used carbon fiber reinforced polymer (CFRP) stays, the material is incredibly expensive and notoriously difficult to "anchor." Steel is predictable. We know how it behaves over 50 years. Carbon fiber is still the "new kid" that most departments of transportation aren't ready to fully trust with a 10-lane highway.

The Resonance Nightmare

Have you ever seen a bridge "gallop"? It's terrifying.

Rain-wind induced vibration is a specific phenomenon that nearly ruined the reputation of cable-stayed bridges in the late 20th century. Basically, when rain coats a cable, it changes the aerodynamic shape. If the wind hits it just right, the cable starts to vibrate violently. These aren't small shakes. We're talking about oscillations that can be several feet wide.

✨ Don't miss: Google Talk for iPhone App: What Really Happened to Gchat

To fix this, engineers do two things. First, they add small ribs or "dimples" to the outside of the HDPE pipe—kinda like a golf ball. This breaks up the wind flow. Second, they install dampers. If you look closely at the base of the cables on a bridge like the Sunshine Skyway in Florida, you’ll see what look like giant shock absorbers. They absorb the energy of the vibration so the cable doesn't shake itself to pieces.

Installation: The Ultimate Jenga Move

Installing cable stayed bridge cables is a logistical headache. You can't just hang them all at once. The bridge is built in "segments." You build a piece of the tower, then you hang a piece of the deck, then you tension a cable to hold that deck piece up. Then you repeat.

The tensioning process is incredibly precise. Hydraulic jacks pull the strands to a specific force, often measured in kips (1,000 lbs). If one cable is too tight, it puts too much stress on the tower. If it's too loose, the deck sags. It’s a constant balancing act. Modern sensors, like fiber-optic Bragg grating sensors, are often embedded directly into the cables now. This allows engineers to monitor the tension in real-time from an office miles away. If a cable loses even a fraction of its "prestress," an alarm goes off.

When Things Go Wrong

We have to talk about the Morandi Bridge in Genoa. It wasn't a standard cable-stayed bridge—it used concrete-encased stays. This was a disastrous design choice by Riccardo Morandi. The concrete hid the corrosion of the steel cables inside. By the time anyone realized the steel was rotting, it was too late. The bridge collapsed in 2018.

This tragedy changed the industry. Today, the mantra is "inspectability." If you can’t see the steel, the design is flawed. Modern cables are designed to be replaceable. You can actually pull out one strand at a time while the bridge is still open to traffic. It’s like changing a guitar string while someone is still playing the song.

Maintenance Realities

Maintenance isn't just about painting. It's about acoustic monitoring.

🔗 Read more: Russian Fifth Generation Fighter: What Most People Get Wrong

Did you know cables "talk"? When a wire inside a cable bundle snaps due to fatigue or corrosion, it makes a sound like a gunshot. Specialized microphones are now permanently attached to many bridges to listen for these "pops." One or two snaps? Not a big deal—the factor of safety is usually around 2.5 or 3.0. But a dozen snaps in a month? That's a sign that the cable is reaching its end of life.

- Visual Checks: Inspectors literally climb the towers or use drones to look for cracks in the outer casing.

- Magnetic Flux Leakage: This is a cool trick where a robotic crawler goes up the cable and uses magnets to "see" inside the HDPE pipe to check for broken wires.

- Vibration Analysis: By measuring how the cable naturally sways, engineers can calculate if the tension has changed.

Future Tech: Beyond Steel

The next frontier is "smart" cables. We’re seeing more integration of graphene-enhanced coatings to provide even better corrosion resistance. There is also a push for "self-sensing" cables where the material itself changes electrical resistance based on the load it's carrying.

But for now, the gold standard remains the multi-strand, wax-filled, HDPE-sheathed steel stay. It’s a system that has been refined through trial, error, and a lot of math. It's why we can build spans like the Russky Bridge in Russia, which has stays reaching nearly 580 meters in length.

Actionable Insights for Bridge Enthusiasts and Pros

If you're involved in civil planning or just an infrastructure nerd, here is what you need to keep in mind regarding cable-stayed technology:

- Prioritize Replaceability: Never sign off on a design where the cables are permanently bonded or encased in a way that prevents individual strand replacement. Access is everything.

- Aeroelasticity is Key: If you're in a high-wind or coastal area, the surface texture of the cable casing (those ribs mentioned earlier) is more important than the color or aesthetic.

- Sensor Integration: Retrofitting sensors is expensive. Installing them during the initial "strand-by-strand" installation phase is much cheaper and provides a baseline for the bridge's entire lifespan.

- Watch the Anchors: The most vulnerable part of the cable isn't the middle; it's the anchor point at the tower and the deck. This is where moisture likes to pool. Ensure these areas have high-quality, replaceable seals and are easily accessible for "hands-on" inspection.

The beauty of these bridges lies in their transparency. Every force is visible. Every cable is doing work. Next time you drive across one, look at those lines. They aren't just architectural flourishes; they are high-performance machines holding your world together.