You’ve seen them everywhere. Those spindly, matte black sticks holding up a slab of live-edge wood or a repurposed door. They’re ubiquitous on Instagram and Pinterest. But honestly, most people are doing it wrong. They buy the cheapest set they can find on a massive e-commerce site, screw them into a heavy piece of oak, and then wonder why the table wobbles every time someone cuts a steak.

Black metal table legs aren't just a trend. They are a utility.

Steel is heavy. It's unforgiving. When you choose the wrong gauge or the wrong profile, your "custom" furniture project starts looking like a middle-school shop class experiment gone wrong. If you want that high-end, industrial-chic look that actually stays sturdy for a decade, you need to understand the physics behind the aesthetics. It’s about more than just a coat of powder-black paint.

The obsession with black metal table legs and why it isn't going away

Interior design cycles usually move fast. We saw the rise and fall of "millennial pink" and the slow death of shiplap. Yet, black metal table legs have stuck around for over a decade. Why? Because black functions as an outline. In a room filled with textures—grainy wood, soft rugs, velvet sofas—the matte black finish provides a visual anchor. It creates a silhouette.

Think of it like a sharp black suit.

Architects like Mies van der Rohe and Le Corbusier understood this a century ago. They used steel frames to allow the "bones" of the furniture to show. Modern homeowners are catching on to that same principle. By using a black metal base, you make the tabletop look like it’s floating. It’s a trick of the eye. It works in a tiny Brooklyn apartment and it works in a sprawling Montana cabin.

But here’s the kicker: not all metal is created equal.

Most "black" legs you find online are actually just thin-walled tube steel that’s been spray-painted. Real industrial legs? They’re usually 10-gauge to 14-gauge cold-rolled steel. If you pick up a leg and it feels light enough to throw like a frisbee, don’t put it under your dining table. Your coffee might end up on the floor.

Stability is math, not just "tightening the screws"

People ask me all the time why their desk shakes. It's almost always the leg geometry.

👉 See also: Sport watch water resist explained: why 50 meters doesn't mean you can dive

Let's talk about the "hairpin" leg for a second. It was invented by Henry Glass in 1941 because of wartime material shortages. It’s iconic. It’s also inherently bouncy. If you put two-rod hairpin legs on a 6-foot dining table, that table is going to oscillate. You need the three-rod version for anything that requires real weight-bearing capacity.

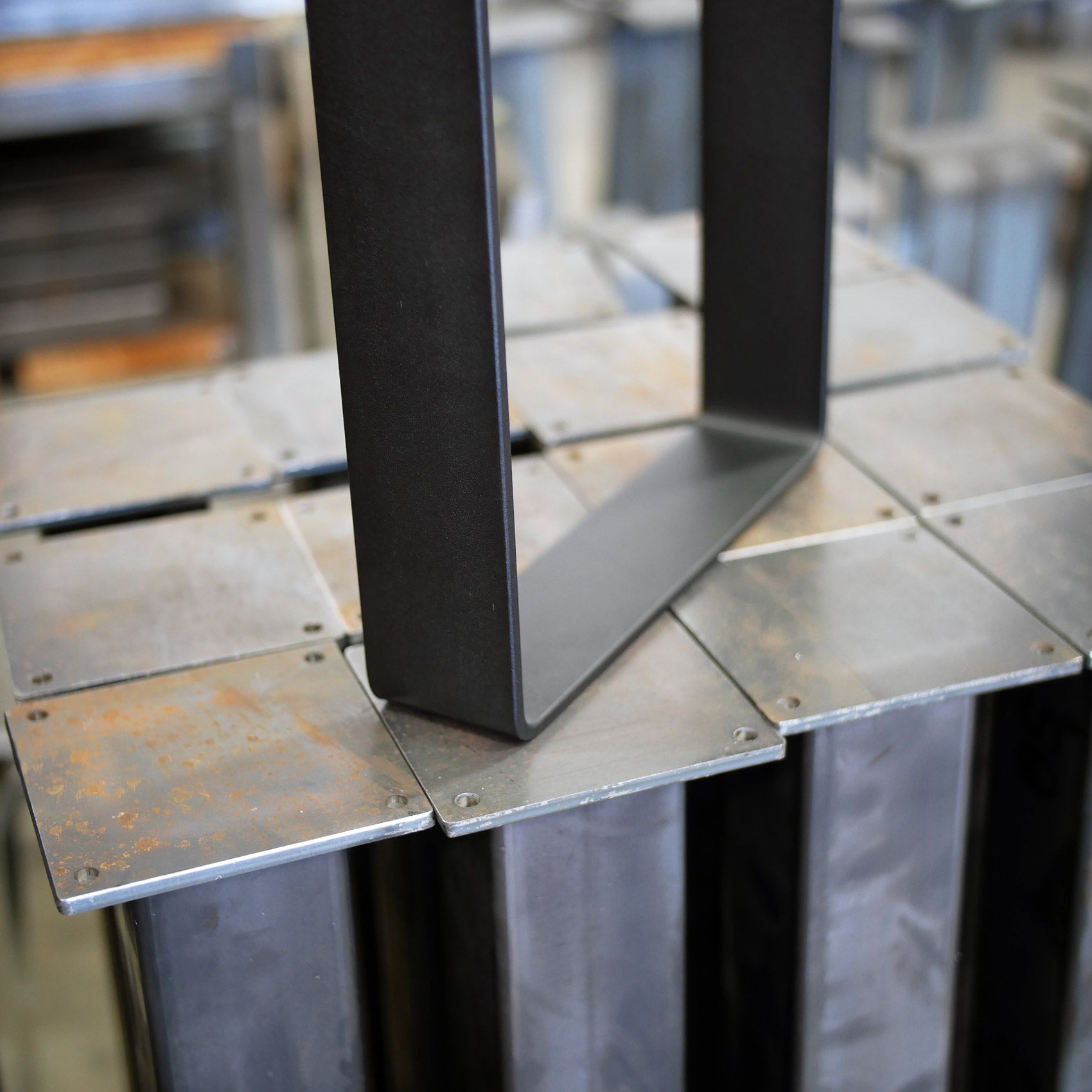

Then you have the U-shape or O-shape frames. These are the workhorses. Because they have a continuous loop of steel, they distribute weight across a larger surface area of the floor. This prevents the "poking" effect where a heavy table might dent your hardwood floors.

Why the mounting plate matters more than the leg itself

I’ve seen $2,000 slabs of walnut ruined because someone used a leg with a tiny, 3-inch mounting plate.

Physics doesn't care about your aesthetic.

When you lean on the edge of a table, you’re creating leverage. That leverage puts immense pressure on the screws. A wide mounting plate—ideally 5 or 6 inches across—spreads that tension. Without it, the wood will eventually strip, or the screws will simply pull out. It’s a mess.

- Top Width: The leg should be at least 70% as wide as the table.

- Thickness: Look for 2-inch or 3-inch tubing for dining tables.

- Finish: Powder coating is the only way to go.

If a manufacturer says "painted finish," run away. Paint chips. It scratches when the vacuum hits it. Powder coating is an electrochemical process where the "paint" is actually baked onto the metal at over 400 degrees. It's basically a plastic armor. It stays matte, it stays black, and it doesn't flake off when your kids kick the table.

Surprising facts about steel and wood movement

Here is something most DIYers completely ignore: wood breathes. Metal does not.

In the winter, your house gets dry. The wood shrinks. In the summer, it swells. If you bolt a rigid black metal frame to a solid wood top with standard round holes, something is going to break. Usually, the wood cracks right down the middle because it has nowhere to go.

✨ Don't miss: Pink White Nail Studio Secrets and Why Your Manicure Isn't Lasting

Expertly fabricated black metal table legs will have "slotted" holes in the mounting plate. These are oval-shaped holes that allow the screws to slide back and forth a few millimeters as the wood expands and contracts. It’s a tiny detail. It’s also the difference between a table that lasts 50 years and one that splits in two years.

Honestly, it's kinda wild how many "professional" furniture makers still get this wrong. Check your hardware. If there are no slots, get out your drill and make some.

The different "Vibes" of black metal

Not all black is the same. You’ve got options, and they change the whole feel of the room.

Matte Black is the standard. It’s flat. It absorbs light. It hides fingerprints. If you have a busy house with dogs and kids, this is your best friend. It looks modern but doesn't scream for attention.

Satin Black has a slight sheen. It looks a bit more "expensive" and formal. It catches the light on the corners of the metal, which highlights the shape of the leg. It’s great for high-end office desks or formal dining rooms.

Textured Black feels like fine-grit sandpaper. It’s extremely durable. It looks very industrial, like something you’d see in a converted warehouse or a high-end brewery.

How much should you actually spend?

Price points are all over the place. You can find a set of four legs for $40, or a custom H-frame for $800.

Where is the sweet spot?

🔗 Read more: Hairstyles for women over 50 with round faces: What your stylist isn't telling you

For a standard desk, expect to pay between $100 and $200 for a quality set of steel legs. Anything cheaper is likely "hollow" feeling and made of thinner metal. For a dining table that needs to seat six people, you're looking at $300 to $500.

I know, it sounds like a lot for "some metal." But remember: the legs are the foundation. If the legs fail, the table is just a pile of wood on the ground. You're paying for the weld quality. Look at the corners. Are the welds ground smooth? Is the transition seamless? High-quality fabricators spend hours grinding and sanding the joints so they look like a single piece of metal.

Cheap legs have messy, "bubbly" welds that look like a bird pooped on the corner.

Dealing with the "Wobble"

Floors aren't flat. They just aren't. Old houses have slopes, and even new builds have slight dips in the subfloor.

When you buy black metal table legs, look for ones with "leveling feet" or threaded inserts at the bottom. These are little plastic or rubber pads that you can screw in or out to adjust the height of each leg individually.

If your legs don't have them, you're stuck using folded-up cardboard or those little felt pads. It looks tacky. Leveling feet are a game changer. They also protect your floors from the raw steel edges.

Actionable steps for your next project

Stop overthinking it and just look at the specs. If you are ready to upgrade your space or build a custom piece, do these things first:

- Check the weight capacity: Don't guess. If your tabletop is a 150-pound slab of concrete, make sure the legs are rated for 300 pounds. You have to account for the weight of people leaning on it.

- Measure your chair height: Standard dining chairs have a seat height of about 18 inches. Your table legs should be 28 to 29 inches tall. If you get 30-inch legs, your guests will feel like children at the adult table.

- Look for 1.5-inch to 3-inch tubing: For a balanced look, the thickness of the metal should roughly match the thickness of your tabletop. Thin legs under a thick slab look like a "lollipop." It’s top-heavy and visually jarring.

- Verify the mounting holes: Ensure they are pre-drilled. Drilling through 1/4 inch steel at home is a nightmare unless you have a drill press and cobalt bits.

- Use the right hardware: Don't use drywall screws. Use heavy-duty lag bolts or wood screws with a wide head (like a pan-head screw) to ensure the metal is sucked tight against the wood.

Black metal table legs are a design staple because they bridge the gap between "rugged" and "refined." They give you the strength of an I-beam with the elegance of a minimalist sketch. Just make sure you aren't sacrificing structural integrity for a low price tag. Your floor, your coffee mug, and your shins will thank you.