You're standing in a puddle. It’s 10:00 PM on a Sunday, you just spilled a glass of Pinot Noir on your cream-colored rug, and your ProHeat 2X Revolution is making a sound like a blender full of gravel. Or worse, it’s not sucking up anything at all. Your first instinct is probably to toss the whole machine in the dumpster and head to a big-box store for a replacement. Honestly, that’s a massive waste of money. Most people don’t realize that finding the right bissell parts for carpet cleaner maintenance is actually pretty straightforward once you stop looking at the machine as a mysterious black box and start seeing it as a collection of swappable components.

Buying a new cleaner costs $200 to $500. A new pump belt? Maybe ten bucks.

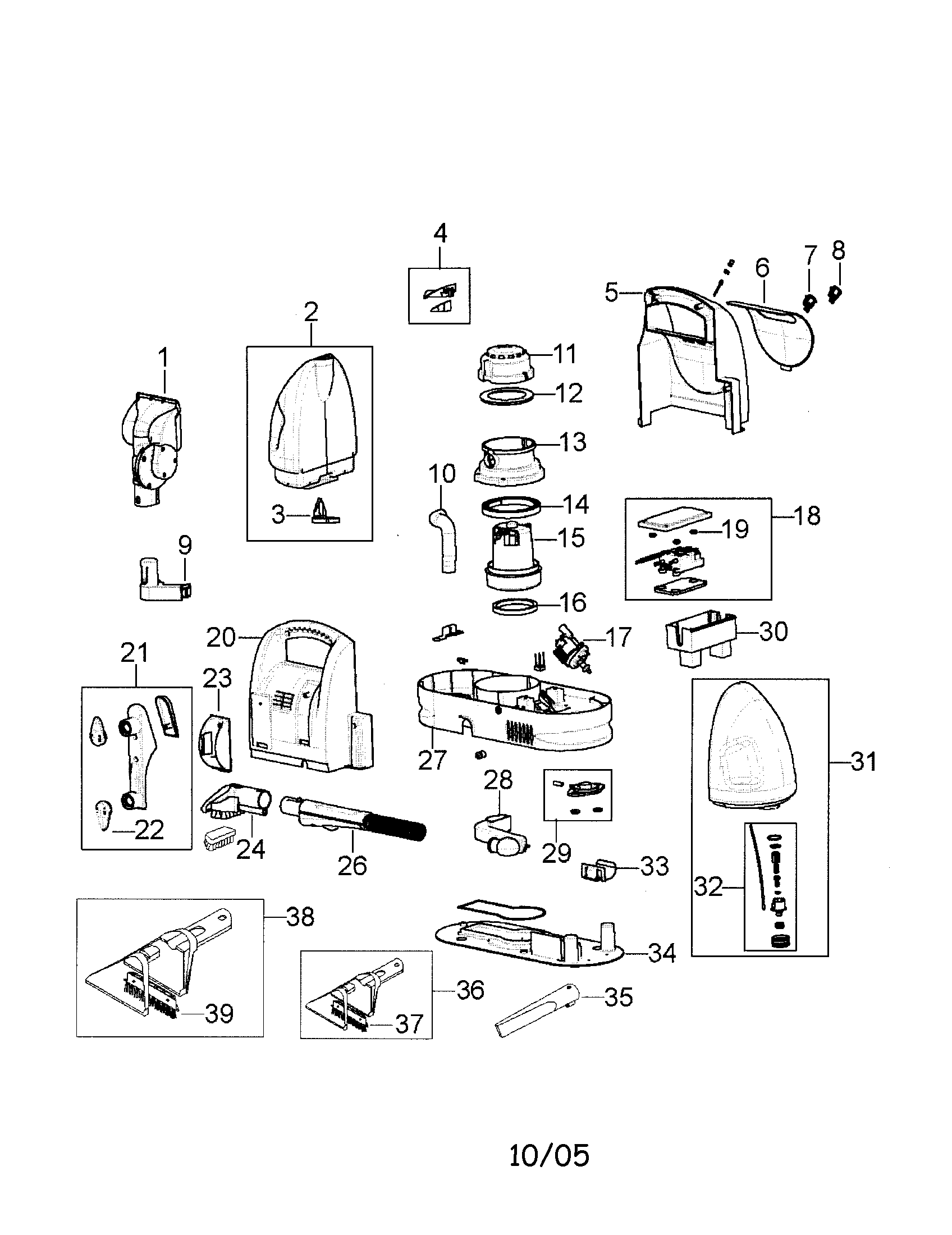

The reality of modern appliances is that they are designed to be modular. Bissell, a company that has been around since Melville Bissell patented a floor sweeper in 1876, actually supports the DIY repair community better than most. They provide detailed schematics for almost every model, from the portable Little Green to the heavy-duty Big Green Machine. But there is a catch. If you buy the wrong version of a spray tip or a brush roll, you aren't just out twenty dollars—you might actually crack the housing of the machine.

The Model Number Trap

Before you even think about clicking "buy" on a replacement water tank or a power cord, you have to find the sticker. This sounds obvious. It isn't. People constantly mistake the "series name" for the model number. If you search for "Bissell ProHeat parts," you'll find about fifteen different variations that are totally incompatible.

You need the actual model number. It's usually on the back or bottom of the unit, printed on a white or silver sticker near the barcode. It’ll look like 1548F, 2007P, or 86T3. That suffix—the letter at the end—matters more than you think. Sometimes a "Series 1" and "Series 2" of the same model use entirely different belt configurations. I’ve seen people strip the gears on their brush motor because they forced a belt that was just three millimeters too short. It's a nightmare.

💡 You might also like: Cooper City FL Zip Codes: What Moving Here Is Actually Like

Why Genuine Parts Actually Matter Here

I’m usually a fan of generic brands. I buy off-brand cereal and generic ibuprofen. But with bissell parts for carpet cleaner longevity, "knock-off" belts and gaskets are a gamble.

The rubber compounds in third-party belts often lack the heat resistance required for high-friction cleaning sessions. Carpet cleaners generate a surprising amount of internal heat. If a cheap belt stretches while you’re mid-scrub, it can slip off and melt against the motor shaft. Now you’re smelling burnt rubber, and you might have a seized motor. Genuine Bissell belts use a specific reinforced cord structure. It’s the difference between a part that lasts five years and one that snaps in five weeks.

The Most Common Failures (And the Parts to Fix Them)

Most carpet cleaner "deaths" are actually just clogs or broken seals. If your machine isn't picking up water, 90% of the time, it’s the Duct Gasket or the Tank Lint Screen. These are tiny, inexpensive pieces of plastic and rubber.

- The Suction Gate: On the front of most uprights, there’s a removable clear nozzle. If this has a hairline crack, your suction drops to zero. You don't need a new motor; you need a $15 front nozzle replacement.

- The Brush Roll: Hair is the enemy. Over time, hair wraps around the bearings of the brush roll, generating heat and melting the plastic end caps. If your brushes aren't spinning, check the bearings before you blame the motor.

- The Solenoid Valve: If the machine runs but won't spray water, and you've already cleaned the spray tips with a paperclip, the solenoid is likely the culprit. This is a bit more technical to replace, involving opening the outer shell, but it's a common failure point if you leave tap water sitting in the machine for months (mineral buildup is a killer).

Don't Overlook the O-Rings

It's the smallest part of all. The tiny rubber O-ring on the bottom of the clean water tank. If this gets pinched or dries out, your machine will leak all over the floor while it's sitting in the closet. Instead of buying a whole new $50 tank, you can usually find an O-ring kit for pennies. Lubricating these with a tiny bit of silicone grease (never WD-40, which degrades rubber) can make a machine feel brand new.

📖 Related: Why People That Died on Their Birthday Are More Common Than You Think

Where to Source Your Parts Safely

You’ve got three main avenues.

- Direct from Bissell: The safest bet. You put in your model number, and they show you the exact exploded view. It's foolproof but sometimes the shipping is slow.

- Authorized Service Centers: These are local vacuum shops. They often have bins of "new old stock" parts. If you're in a rush, call a local repair shop and ask if they have your specific part number. They might even give you a tip on how to install it.

- Third-Party Marketplaces: Great for discontinued models. If you have an ancient Bissell from the 90s, eBay is your best friend. Just make sure the seller lists the specific part number (like 1606428) rather than just a generic description.

The Ethics of Repair vs. Replace

We live in a "throwaway" culture, but carpet cleaners are remarkably mechanical. Unlike a smartphone with a glued-in battery, a Bissell is held together mostly by Philips head screws. There's a certain satisfaction in taking apart a machine that "died," clearing out a massive clump of pet hair from the internal hose, replacing a $12 belt, and watching it suck dirt out of a rug again.

It’s better for your wallet. It’s better for the landfill.

However, there is a "point of no return." If the motor housing itself has cracked or if the internal wiring has shorted out due to a major leak, the cost of the motor plus your time might outweigh the value of the machine. But for things like nozzles, tanks, hoses, and brushes? Always repair.

👉 See also: Marie Kondo The Life Changing Magic of Tidying Up: What Most People Get Wrong

A Quick Troubleshooting Checklist

If your machine is acting up, run through this before ordering bissell parts for carpet cleaner restoration:

- Check the float stack in the dirty water tank. If it's stuck "up," the machine won't have suction.

- Inspect the "red" lint filter. It's usually tucked behind the tank. If it's clogged, the motor will overheat.

- Verify the pump prime. Sometimes you just need to hold the trigger for 30 seconds to get the air out of the lines.

Maintaining the New Parts

Once you've done the work, don't let it go to waste. The number one reason parts fail is "storage neglect."

Always, always rinse the dirty water tank and the floor nozzle after use. If you leave carpet cleaning solution in the lines, it can crystallize and clog the tiny spray orifices. Run a tank of plain warm water through the machine after you finish your carpets. This flushes the chemicals out of the pump and the spray tips, ensuring that the next time you have a red wine emergency, your machine actually works.

Also, keep a spare belt taped to the side of the machine or tucked in a drawer. Belts have a habit of snapping at the worst possible moment. Being prepared makes the difference between a minor 10-minute fix and a ruined weekend.

Actionable Steps for Your Repair

- Locate the white sticker on your machine and write down the exact model number.

- Download the parts schematic from the manufacturer's website to identify the specific part number you need.

- Inspect the gaskets and seals first; they are the most common cause of suction loss and are the cheapest to fix.

- Order genuine reinforced belts if yours have stretched or snapped, as they handle the torque of the motor significantly better than generic alternatives.

- Clean the spray tips with a thin wire before assuming you need a new pump or solenoid.

- Perform a "clear water flush" after every use to prevent mineral buildup and chemical crystallization in the internal hoses.