You’re sitting in the grease-scented waiting room, scrolling through your phone, when the service advisor walks in holding a clipboard like it’s a death warrant. He says the alternator replacement is going to take 3.4 hours. You’ve seen a YouTube video where a guy did it in twenty minutes. You feel that sudden, sharp itch in your wallet. It feels like a scam, right? It isn’t. Well, usually it isn’t.

Understanding automotive repair labor times is basically like learning a secret language that dictates exactly how much of your paycheck goes to the local garage. It's not just "how long the guy worked." It's a complex, data-driven system built on decades of timing studies, specialized software, and a fair bit of industry friction. If you’ve ever wondered why a "five-minute fix" cost you two hours of labor, you’re looking at the weird world of the "flat rate" system.

The Flat Rate Reality

Most shops don't bill by the wall clock. They use a flat rate system. This means if a guide says a water pump on a 2018 Ford F-150 takes 4.2 hours, that is what you pay. It doesn't matter if the technician is a wizard who finishes in two hours or a rookie who struggles for six. The shop wins if they're fast; you win if they're slow. Sorta.

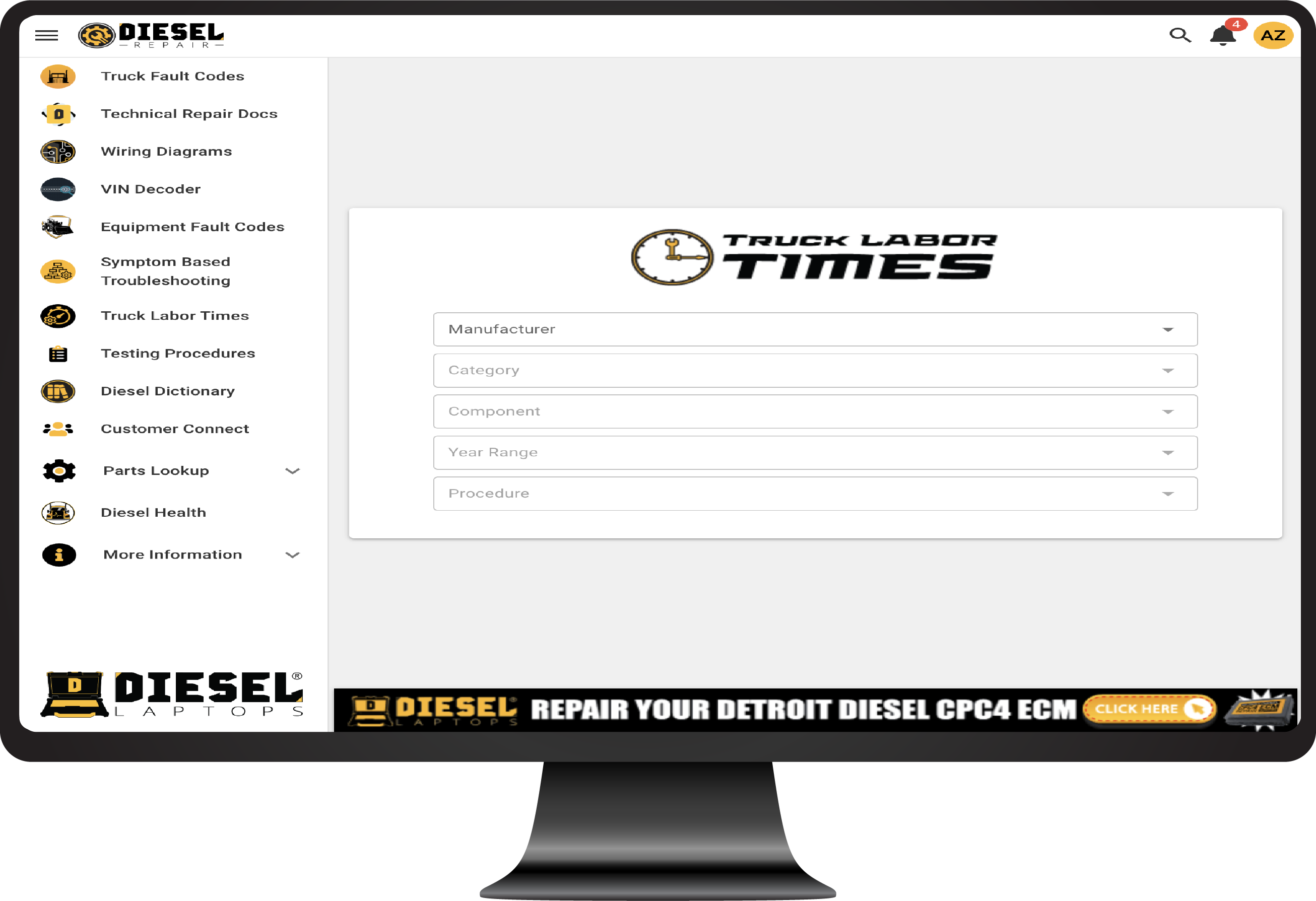

This system relies on massive databases. We're talking about heavy hitters like Mitchell 1, Motor, and AllData. These companies literally employ people to take cars apart and put them back together while holding stopwatches. They factor in "book time," which is the theoretical time a technician needs to perform a task in a perfect world with perfect tools.

But here’s the kicker: cars aren’t perfect.

Rust happens. Bolts snap. Previous owners do "custom" wiring jobs that look like a bird’s nest made of copper. The automotive repair labor times listed in the book assume the car is relatively clean and the tech has every specialized tool at arm's reach. In the Rust Belt, a three-hour suspension job can easily turn into a six-hour nightmare because the control arm bolts have effectively welded themselves to the frame.

Why the "Book" and Reality Disagree

Ever heard of the "warranty time" vs. "customer pay" discrepancy? It’s a huge point of contention in the industry. Manufacturers (the OEMs) have their own labor time guides for warranty work. These times are notoriously stingy. If a dealership tech does a warranty repair, the manufacturer might only pay them 1.8 hours for a job that the aftermarket guides (like Mitchell) say should take 2.5 hours.

👉 See also: E-commerce Meaning: It Is Way More Than Just Buying Stuff on Amazon

Mechanics hate warranty work. It’s a known fact in the bays. They call it "getting killed on the clock." Because of this, shops often use the more generous aftermarket guides for you—the "customer pay" client—to ensure they actually make a profit and can pay their techs a living wage. It’s a business, after all.

How the Data is Actually Made

You might think these numbers are just pulled out of thin air. They aren't. Companies like Motor Information Systems have been doing this for over a century. They use a "Methodology of Labor Time Development."

- Physical Teardowns: They actually perform the repair.

- Time Studies: They observe technicians of varying skill levels.

- Manufacturer Data: They review the technical service bulletins (TSBs).

- Logic Adjustments: They add "overlap" time.

Let’s talk about overlap because that’s where you can actually save money if you’re smart. If you are getting your timing belt replaced, the water pump is usually right there. If a shop tries to charge you the full "stand-alone" labor time for both, they’re double-dipping. Most professional software automatically calculates "overlap" to subtract the time spent getting to the shared area. If you're paying for 5 hours for a timing belt and 3 hours for a water pump, someone is likely trying to pull a fast one. It should be 5 hours plus maybe an extra 0.5 for the pump itself.

The Human Element: Skill vs. Speed

There is a massive divide between a "Parts Changer" and a "Diagnostic Technician."

Diagnostic time is the most misunderstood part of automotive repair labor times. People get furious when they see a $150 charge for "Diagnostic Fee" on their bill. "You just plugged in a scanner!" they say. Honestly? No. The scanner just points you in a direction. Finding a parasitic battery drain or a hairline crack in a vacuum hose takes actual brainpower and specialized equipment like oscilloscopes or smoke machines.

Most shops charge a flat one-hour diagnostic fee. If the problem is incredibly complex—think intermittent electrical ghosts—they might call you and ask for "another hour of Diag." This isn't a ransom. It’s because the tech is literally sitting there with a multimeter instead of turning wrenches on a high-profit brake job.

✨ Don't miss: Shangri-La Asia Interim Report 2024 PDF: What Most People Get Wrong

The "Add-On" Trap

You’ll often see "Shop Supplies" or "Environmental Fees" tacked onto the labor. This covers things like brake cleaner, rags, floor sealant, and the cost of disposing of your old oil. While it’s not strictly "labor time," it’s baked into the cost of the labor performed.

A Look at Common Repairs

Let's look at some real-world averages for automotive repair labor times so you have a baseline. These fluctuate based on the vehicle’s make and model. A German luxury car will almost always have higher labor times than a domestic sedan because engineers in Stuttgart seem to enjoy hiding simple components under twelve layers of plastic.

- Front Brake Pads: Usually 1.0 to 1.5 hours. This includes the "lopping" of rotors or replacing them.

- Alternator Replacement: Anywhere from 1.5 to 4.0 hours. On some transverse-mounted V6 engines, you basically have to be a surgeon to get the thing out.

- Clutch Replacement: This is a big one. Expect 5.0 to 9.0 hours. You're literally splitting the car in half.

- Spark Plugs (4-cylinder): 0.5 to 1.0 hour.

- Spark Plugs (Transverse V6): 2.0 to 4.0 hours. Why? Because the intake manifold often has to come off just to reach the back three plugs.

The Regional Difference

Labor times are static, but labor rates are wild. In rural Kansas, the shop rate might be $90 an hour. In downtown San Francisco or Manhattan, you could easily see $250 or more. This is why a "three-hour job" costs $270 in one place and $750 in another. Same book, different economy.

Independent Shops vs. Dealerships

Dealerships almost always have higher labor rates, but they also have the most specific tools. They have the factory-level scanners that can "talk" to every single module in your car. An independent shop might have a "universal" scanner that can only see 80% of the data. Sometimes, the extra labor time at an independent shop—spent trying to figure out a weird coding issue—actually makes it more expensive than just going to the dealer who has the "one-click" fix.

Negotiation and Transparency

Can you negotiate automotive repair labor times? Not really. The "book" is the bible for most service writers. What you can negotiate is the labor rate or the parts markup.

If a shop tells you a job takes 5 hours and you find three other shops saying it takes 3 hours, call them out. They might be using a different guide, or they might be "padding" the estimate. Padding is rare in reputable shops but it happens. Always ask: "Which labor guide are you using?"

🔗 Read more: Private Credit News Today: Why the Golden Age is Getting a Reality Check

If they can't answer, walk away.

The Future of the Clock

Everything is changing with Electric Vehicles (EVs).

Traditional automotive repair labor times are heavily skewed toward internal combustion engines. Oil changes, exhaust work, transmission flushes—these are the bread and butter of the industry. EVs don't have those. However, their labor times for battery coolant flushes or high-voltage cable inspections are becoming the new standard.

The complexity is shifting from mechanical to software. We are seeing more "labor time" assigned to software flashes and module programming. Sometimes a car won't start because of a software bug, and the "repair" is just a 45-minute download. You're still paying for that hour of labor because that specialized laptop the tech is using costs the shop $10,000 plus an annual subscription fee.

Actionable Steps for Your Next Repair

Knowledge is your only shield against getting overcharged.

- Ask for the printed estimate: Ensure the labor hours are listed separately for each task. Look for the "overlap" mentioned earlier.

- Check the guide: Sites like RepairPal or Kelley Blue Book have "Fair Repair" estimators. They use the same data as the pros. If your quote is significantly higher than their range, ask why.

- Identify the "Real" Tech: Ask if a "Master Tech" or an "A-Level Tech" will be doing the work on complex engine or electrical issues. If you're paying top-tier labor rates, you shouldn't have a "C-Level" apprentice learning on your car.

- Photo Evidence: If a shop says a bolt broke or they found "unexpected damage" that adds two hours to the job, ask for a photo. Every tech has a smartphone in their pocket.

The relationship between a car owner and a mechanic is built on trust, but that trust is verified by the numbers. Understanding how those hours are calculated turns you from a "victim" of the invoice into a partner in the repair process. You’re not just paying for time; you’re paying for the specialized knowledge of how to beat the clock without breaking the car.