You're staring at a tangled nest of wires in a breaker panel. You need to know if that circuit is overloaded, but there is no way you're cutting into a live wire to insert an ammeter in series. This is exactly why the AC DC current clamp meter exists. It’s basically magic—or, more accurately, physics—allowing you to measure flow without touching a bare conductor. But honestly, most people grab the first cheap one they see on Amazon and end up wondering why their DC readings are drifting or why the clamp won't fit around a thick battery cable.

It’s a specialized tool.

Back in the day, clamp meters were strictly for AC. They relied on simple transformer action. But modern electronics, solar arrays, and electric vehicles (EVs) live and breathe DC. If you're troubleshooting a Tesla charging port or a solar inverter, a standard AC-only clamp is about as useful as a chocolate teapot. You need the Hall Effect sensors found in a dedicated AC DC current clamp meter to actually see what's happening.

The Hall Effect vs. Transformer Action

Why does the distinction matter? Traditional AC clamps work like a transformer. The wire you're clamping acts as the primary winding, and the internal core of the clamp acts as the secondary. It’s elegant and doesn't require much power. However, DC doesn't create a changing magnetic field that can "induce" current in a transformer. It's static.

📖 Related: Why the Radio FM CD Player Still Wins in a World of Streaming

To solve this, manufacturers like Fluke and Klein use Hall Effect sensors. These tiny semiconductors sit in a gap in the clamp's jaws. They detect the actual strength of the magnetic field, regardless of whether it's pulsing (AC) or steady (DC).

Precision isn't just a buzzword

Cheap meters often struggle with "remanence." This is basically magnetic memory. If you just measured a massive DC surge and then try to measure a small 500mA signal, the jaw might still be slightly magnetized. This gives you a "ghost" reading. A high-quality AC DC current clamp meter will have a robust "Zero" button. You have to press it every single time you switch to DC mode. If you don't, your data is basically fiction.

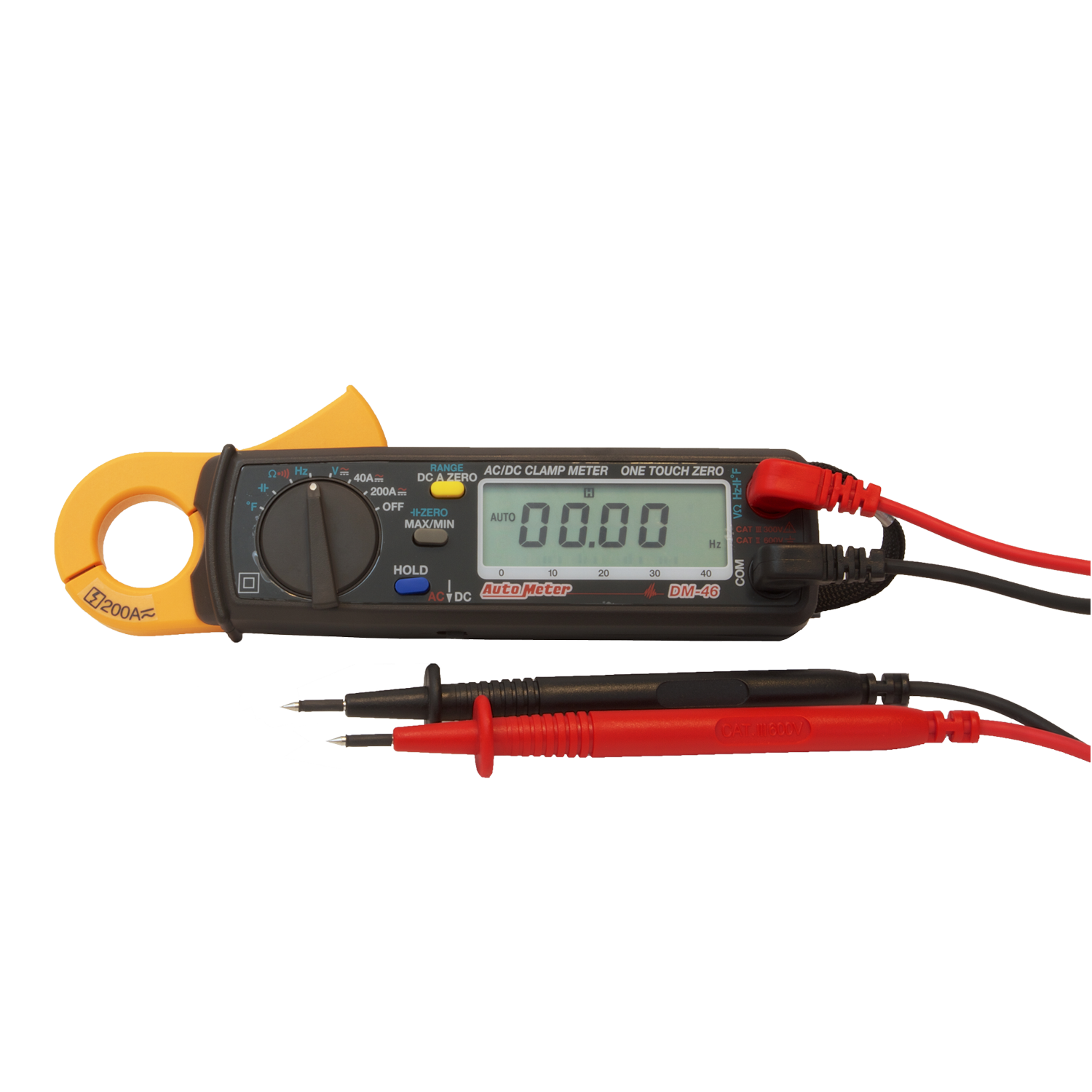

Choosing the Right Jaw Size for the Job

Size matters. Not just for the sake of it, but because of physics. If you buy a massive clamp meant for industrial busbars and try to measure a 14-gauge wire in a residential wall, your accuracy drops. The wire should ideally be centered in the jaw.

- Sub-compact clamps: Great for HVAC techs. They fit into tight furnace control boards.

- Standard 30mm jaws: The "Goldilocks" zone for most residential and light commercial work.

- Large 50mm+ jaws: Necessary for 4/0 cables or parallel feeds in industrial settings.

I’ve seen guys try to "force" a clamp shut over a bundle of wires. Never do that. If the jaw isn't perfectly snapped shut, the magnetic circuit is broken. Your reading will be wildly lower than reality. It’s a safety issue, too. A partially open jaw in a high-voltage environment is just asking for an arc flash if something slips.

True RMS: Don't Settle for Average

If you are working on anything modern—LED lighting, variable frequency drives (VFDs), or computer power supplies—you absolutely need a True RMS AC DC current clamp meter.

✨ Don't miss: What Is Latest iPhone iOS: The Truth About iOS 26 and What You Actually Need

Standard meters assume every AC signal is a perfect, pretty sine wave. But electronics "chop" the power, creating messy, distorted waveforms. An "averaging" meter will be off by 30% or 40% on these loads. True RMS (Root Mean Square) uses complex math to calculate the actual heating potential of the current, giving you the truth even when the power is "dirty."

Companies like Fluke (specifically the 376 FC model) or Hioki are the gold standard here. They use high-speed sampling to get that RMS value right. If you’re a hobbyist, maybe you don't care. But if you’re billing a client for diagnostic work, showing up with a non-RMS meter is unprofessional and potentially dangerous for the equipment you're testing.

Inrush Current: The Secret Killer of Motors

One of the coolest features of a high-end AC DC current clamp meter is the "Inrush" function. When a motor starts—like your AC compressor or a heavy industrial pump—it gulps a massive amount of current for a fraction of a second. This can be 5 to 10 times the running current.

Most meters are too slow to catch this. They "average" the spike, showing you a number that looks fine while your breakers keep tripping. An Inrush-capable meter triggers on the surge and captures the peak. This lets you know if the motor windings are starting to fail or if the start capacitor is shot.

Safety Ratings: CAT III and CAT IV Explained

Don't ignore the markings on the bottom of the meter. These aren't suggestions.

- CAT III 600V: Good for most residential and commercial indoor work.

- CAT IV 600V / CAT III 1000V: Necessary if you're working on the "service side" of the meter (the wires coming from the utility pole).

A high voltage spike on a low-rated meter can literally turn the tool into a grenade in your hand. The internal clearances and fuse protection in a CAT IV meter are vastly superior.

The Problem with Ghost Voltages

Sometimes, you’ll see a voltage reading on your clamp meter even when the wire is disconnected. This is "ghost voltage" caused by capacitive coupling from nearby live wires. It’s annoying. Professional AC DC current clamp meters often have a "LoZ" (Low Impedance) mode. This puts a small load on the circuit, which collapses those ghost voltages so you can see if the wire is truly dead. It's a lifesaver—literally.

Real-world Example: Solar Troubleshooting

Imagine a 100kW solar array. You have dozens of strings of panels feeding into a combiner box. One string is underperforming. You can't easily disconnect every single MC4 connector to test with a multimeter.

With an AC DC current clamp meter, you just clamp each string while the system is live. You're looking for the outlier. If ten strings are pulling 8.5 amps and one is pulling 2.1 amps, you’ve found your problem in seconds. This is where DC accuracy is paramount. A meter that drifts even half an amp can make a healthy string look like a failing one.

Practical Steps for Accurate Measurements

To get the most out of your tool, follow a strict workflow.

🔗 Read more: Finding the Right Clip Art of the Globe Without Looking Like a 90s Math Textbook

- Inspect the Jaws: Ensure there’s no dust or metal shavings on the mating surfaces. Even a tiny gap ruins the magnetic loop.

- Zero Out: If measuring DC, hold the meter in the same orientation you'll use for the measurement, then hit the Zero button.

- Single Conductor Only: Never clamp around a power cord (like an extension cord). The current going out and the current coming back cancel each other out, and you’ll get a reading of zero. You must separate the "hot" wire.

- Use the Min/Max Function: If you're looking for intermittent drops, leave the meter clamped and let it record the peaks and valleys while you're at the control panel.

- Check Your Batteries: A low battery in a Hall Effect meter is the #1 cause of wonky DC readings.

If you're looking to buy, don't just look at the price tag. Consider the environment. Do you need a backlit display for dark basements? Do you need Bluetooth connectivity (like Fluke Connect) so you can read the meter from outside a hazardous arc-flash zone? These features aren't just "extra"—they change how you work.

The next time you're troubleshooting a parasitic drain on a car battery or verifying the load on a sub-panel, remember that the AC DC current clamp meter is only as good as the person who knows how to zero it and check for True RMS. Invest in a tool that matches the complexity of the systems you're fixing. Check the CAT rating, verify the DC range, and always, always keep the jaw surfaces clean. This is the difference between guessing and knowing.