You’re staring at a tiny bolt, a camera lens, or maybe a piece of jewelry, and you need to know exactly how big it is in "American." It happens to the best of us. We live in a world where the United States stubbornly clings to the imperial system while the rest of the planet—and most scientific industries—runs on millimeters. So, how much is 8mm in inches?

The short, no-nonsense answer is $0.31496$ inches.

But honestly, nobody walks around saying "three-hundred-and-fourteen thousandths." If you’re at Home Depot or working in a garage, you’re looking for a fraction. In that world, 8mm is just a hair over 5/16 of an inch. It’s that annoying middle ground where a 5/16 wrench almost fits, but then it rounds off the corners of your bolt and ruins your afternoon.

Understanding this conversion isn't just about math; it's about not stripping screws or buying the wrong size nose ring.

The Math Behind 8mm in inches

Let’s get the technical stuff out of the way. To convert millimeters to inches, the standard constant is 25.4. You take your millimeter figure and divide it by 25.4.

$$8 \div 25.4 = 0.31496062992...$$

Most people just round that to 0.315.

If you’re trying to visualize that, think about a standard pencil. The diameter of a standard wooden #2 pencil is usually around 6mm to 7mm. So, 8mm is just a bit thicker than your average yellow Ticonderoga. It’s small, but in the world of engineering, a fraction of a millimeter is a canyon.

I’ve seen people try to use an 8mm socket on a 5/16-inch nut. A 5/16-inch nut is exactly 0.3125 inches. The 8mm socket is 0.3150 inches. That’s a difference of $0.0025$ inches. It feels like a perfect fit until you apply real torque, and then—snap—you’ve got a smooth, round piece of metal where a bolt head used to be. Precision matters.

Why 8mm is the "Magic Number" in Film and Tech

When we talk about 8mm in inches, we aren't always talking about hardware. For a huge chunk of the 20th century, 8mm was the heartbeat of home movies.

Eastman Kodak introduced the 8mm film format back in 1932 during the Great Depression. They wanted something cheaper than 16mm. They basically took 16mm film, doubled the number of perforations, and ran it through the camera twice. It was a genius move.

If you find an old reel of Super 8 film in your grandma's attic, that strip of plastic is roughly 0.315 inches wide. It seems tiny, doesn't it? It’s wild to think that entire childhoods and family vacations were captured on a sliver of celluloid barely wider than a pea.

Then you have the tech world. Most smartphone camera sensors or small laptop cooling fans are measured in millimeters. If a manufacturer tells you a device is 8mm thick, they’re bragging about a "slim" profile that translates to less than a third of an inch.

Jewelry, Piercings, and Why You Should Care

If you're shopping for a septum ring, a "plug" for stretched ears, or a necklace chain, you're going to see 8mm everywhere. This is where the conversion gets personal.

In the body piercing world, 8mm is the standard "0 gauge" or "0g" equivalent? No, wait—that’s a common mistake. Actually, 8mm is specifically a 0 gauge in the American Wire Gauge system used for ear stretching.

If you buy an 8mm jump ring for jewelry making, it’s going to look roughly like the diameter of a standard drinking straw. If you're buying a wedding band, 8mm is considered a "wide" band for a man's finger. Most standard men's rings are 6mm, so jumping to 8mm gives it a heavy, substantial look on the hand.

Common Practical Comparisons for 8mm

Sometimes numbers don't help. You need to see it in your head.

- A standard AA battery: The diameter is about 14mm. So 8mm is a little over half the width of a battery.

- A 5/16 inch drill bit: This is the closest common fractional size you’ll find in a standard American toolkit.

- A Stack of Nickels: Two US nickels stacked on top of each other are about 3.9mm thick. So, four nickels stacked up is just shy of 8mm.

- The "Leg" of a Staple: A standard office staple is usually about 1/4 inch or 6mm.

Why the US Won't Give Up the Inch

It’s frustrating. You’re working on a car, and you need a "ten mil" (which everyone loses, by the way), but your dad’s old toolkit is all in inches.

The United States actually "officially" adopted the metric system in 1875 by signing the Treaty of the Meter. We just... didn't tell anyone. Or rather, we didn't force people to change.

The Metric Conversion Act of 1975 was supposed to fix this, but it was voluntary. Since big industries like construction and land surveying were already built on feet and inches, the cost of switching was too high. So, we live in this weird dual-reality where your soda comes in a 2-liter bottle, but your milk comes in a gallon, and you have to Google 8mm in inches while fixing your German-made car with American tools.

Precision Engineering: When "Close Enough" Isn't

In high-end manufacturing, like at NASA or in medical device production, they don't use fractions. They use "thous"—thousandths of an inch.

If a machinist is making a part that is 8mm, they are aiming for $0.3149$. If they hit $0.3155$, the part might not fit into its housing.

👉 See also: How Many Days Until January 14? Why This Date Quietly Rules the Winter Calendar

Think about it this way:

A human hair is roughly $0.003$ inches thick. The difference between 8mm and a 5/16-inch tool is $0.0025$ inches. That means the "slop" or the gap is less than the thickness of a single hair on your head. That is why using the wrong unit of measurement is such a disaster in mechanics.

Actionable Tips for Working with 8mm

If you find yourself constantly switching between these two worlds, stop trying to do the mental math. You'll eventually mess up a decimal point.

- Buy a digital caliper. Seriously. You can get a decent one for twenty bucks. You can slide it open, hit a button, and it toggles between mm and inches instantly. It takes the guesswork out of measuring bolt diameters or material thickness.

- Memorize the "Big Three" Conversions. - 6mm is roughly 1/4 inch.

- 8mm is roughly 5/16 inch.

- 13mm is roughly 1/2 inch.

- Check the Head Marks. If you're looking at a bolt and it has numbers on the head (like 8.8 or 10.9), it’s metric. If it has radial lines (dashes), it’s imperial. Never mix the tools once you’ve identified the bolt.

- Jewelry sizing is different. If you are buying a watch, a 38mm or 40mm case is the standard. An 8mm thick watch is considered "ultra-thin" and dressy.

It's easy to dismiss 8mm as just another small number. But whether it's the width of a vintage film strip, the thickness of your next smartphone, or the size of a structural bolt holding your brake caliper together, that $0.3149$ inches represents a world of precision.

Don't settle for "close enough." When you're dealing with 8mm, "close enough" is usually the start of an expensive mistake. Use a dedicated conversion chart or a digital tool to ensure that your 5/16-inch wrench isn't about to turn your 8mm bolt into a useless piece of scrap metal.

Stick to the decimal $0.315$ for general DIY projects, but keep that $0.31496$ in your back pocket if you’re doing anything that requires real accuracy. It’s a small difference, but in the right context, it’s everything.

Next Steps for Accuracy

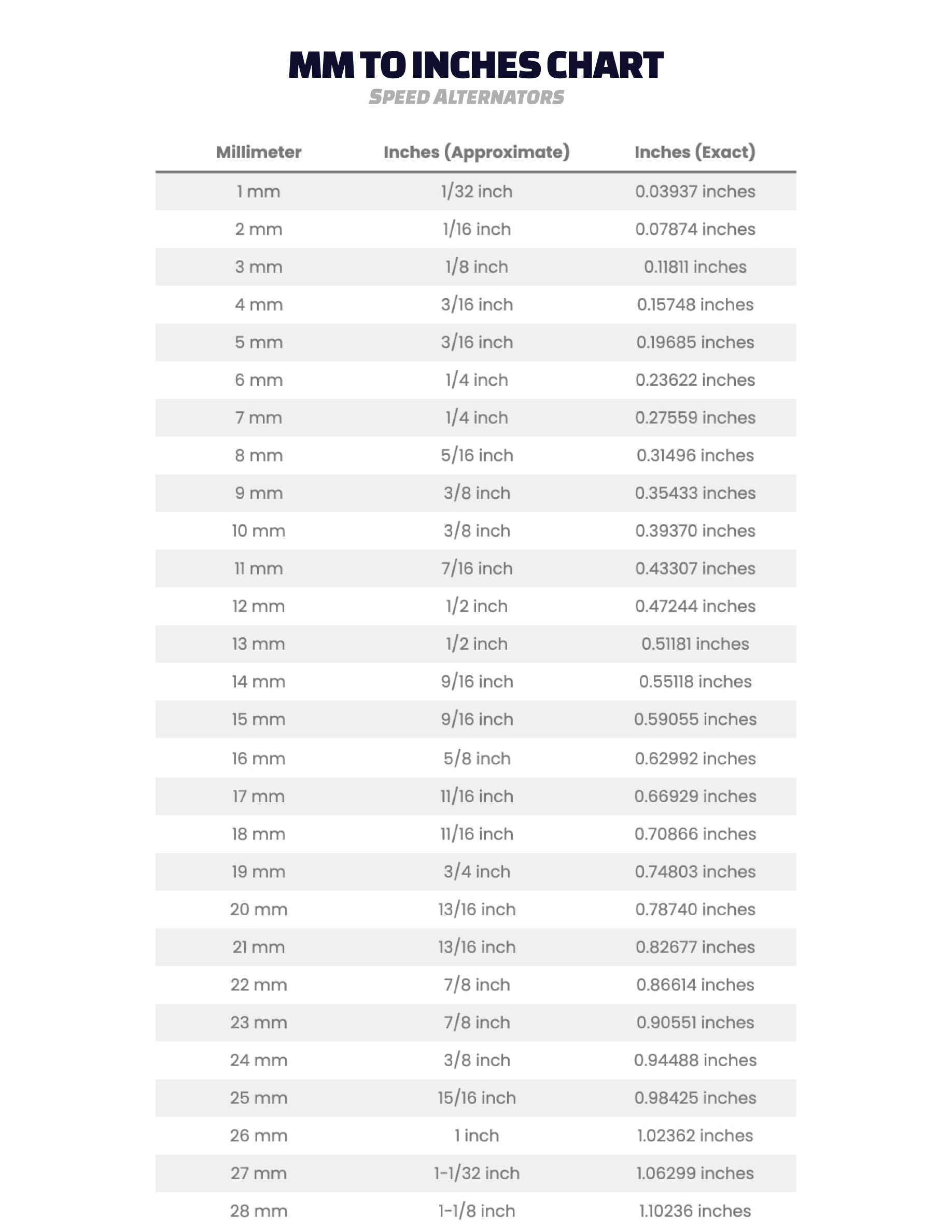

- Download a PDF conversion chart: Keep a printed copy of metric-to-fractional-inch equivalents on your workshop wall or inside your toolbox lid.

- Invest in a "Thread Pitch Gauge": This tool helps you identify if a bolt is metric or imperial before you even reach for a wrench.

- Verify Jewelry Gauges: If ordering body jewelry, always ask for the measurement in millimeters rather than gauge sizes, as "8mm" is an absolute measurement while "gauge" can vary slightly by manufacturer.