You’ve probably been there. You go to plug your favorite pair of cans into a flight adapter or an old stereo, and something just feels... off. Maybe it clicks but there’s no sound. Maybe you only hear audio in the left ear unless you wiggle the cable like you’re trying to pick a lock. It’s a 3.5 mm jack. It should just work. But the reality of 3.5 mm jack dimensions is way more annoying than the "standard" name suggests.

Standardization is a bit of a lie in the audio world.

While the diameter is roughly 3.5 millimeters, the actual physical blueprints for these connectors involve tolerances that would make a machinist sweat. If the sleeve is a fraction of a millimeter too long, or the "tip" isn't shaped with the exact right radius, the internal spring contacts of your device won't seat properly. You end up with static. Or worse, a port that gets stretched out over time.

The Actual Blueprints: It's Not Just a Metal Stick

When we talk about 3.5 mm jack dimensions, we are technically looking at the miniature version of the 1/4 inch (6.35 mm) phone connector that dates back to 19th-century telephone switchboards. Seriously. The tech in your iPhone (back when it had a jack) is a direct descendant of Victorian-era engineering.

The outer diameter of the plug is usually specified at $3.5 \text{ mm} \pm 0.1 \text{ mm}$. That seems simple. But the complexity lies in the longitudinal measurements.

A standard TRS (Tip-Ring-Sleeve) plug has a total length from the base of the plastic housing to the very tip of about 14 mm to 15 mm. The "Tip" is generally 3.5 mm long. The "Ring" (the middle segment) is around 3 mm. Then you have the "Sleeve," which is the longest part at the base. These are separated by tiny insulating rings—usually black or green plastic—that prevent the signals from shorting out against each other.

If you look closely at a high-end connector from a brand like Neutrik or Amphenol, you’ll notice the tip isn't just a point. It’s a specific conical shape. If that cone is too sharp, it can actually damage the delicate leaf springs inside a female port. If it’s too blunt, it won’t "click" into place. This is why a $2 cable from a gas station feels "crunchy" when you plug it in, while a quality cable feels smooth. It’s all about those micro-tolerances in the machining process.

TS vs. TRS vs. TRRS: Why Your Mic Doesn't Work

This is the biggest headache.

👉 See also: What Is Hack Meaning? Why the Internet Keeps Changing the Definition

You see the stripes? Those little plastic bands? They aren't just for decoration. They define the electrical layout of the jack.

- TS (Tip-Sleeve): Two conductors. You see one stripe. This is mono. You’ll mostly find this on patch cables for synthesizers or very cheap microphones. If you plug this into a stereo jack, you’ll likely only hear audio on the left side because the sleeve is shorting the right-channel contact to ground.

- TRS (Tip-Ring-Sleeve): Two stripes. This is your standard stereo headphone jack. Tip is Left, Ring is Right, and Sleeve is Ground. This has been the gold standard since the Walkman era.

- TRRS (Tip-Ring-Ring-Sleeve): Three stripes. This adds a fourth conductor for a microphone signal.

Here is where the 3.5 mm jack dimensions get truly messy. Even though the overall length of the metal part stays the same (roughly 14-15 mm), the way those four sections are divided varies by brand.

Back in the early 2010s, there was a massive "format war" between CTIA and OMTP. Apple and most modern smartphone makers use the CTIA standard, where the microphone is on the sleeve and ground is on the second ring. Older Nokia or Samsung phones used OMTP, which swapped those two. If you mix them up, the audio sounds like it's underwater because the ground path is wrong. It's a mess.

The "Shoulder" Problem

Have you ever had a phone case that was just a little too thick?

This is a physical dimension issue that people ignore. The "shoulder" is the plastic or metal housing that sits right at the base of the metal plug. Most high-performance audio cables have a thick, beefy shoulder for durability. But if you're trying to plug that into a smartphone with a protective case, the shoulder hits the case before the plug is fully seated.

Even if the 3.5 mm jack dimensions of the metal part are perfect, that extra millimeter of plastic can prevent a connection. This is why "stepped" designs exist—where the metal base extends slightly before the plastic begins—to clear the thickness of a phone case.

Wear, Tear, and the 5,000-Cycle Myth

Most manufacturers claim their 3.5 mm female ports are rated for 5,000 "mating cycles."

✨ Don't miss: Why a 9 digit zip lookup actually saves you money (and headaches)

That sounds like a lot. It isn't.

If you’re a commuter who plugs and unplugs their headphones four times a day, you’ll hit that limit in about three years. What actually happens? The "tines" or springs inside the port lose their tension. Because the 3.5 mm jack dimensions rely on physical friction, once those internal springs stop pushing hard against the tip and rings, you lose the connection.

Also, pocket lint.

Seriously. Most "broken" 3.5 mm jacks are just full of compressed denim fibers. Because the jack is 15 mm deep, lint gets shoved to the bottom every time you plug in your headphones. Eventually, there’s enough gunk at the bottom that the plug can’t reach the final millimeter needed to click.

Is the 4.4 mm Pentaconn the Future?

While we're talking about dimensions, we have to mention the 3.5 mm's bigger brother.

Audiophiles are moving toward the 4.4 mm "Pentaconn" connector. Why? Because 3.5 mm is fundamentally limited. It shares a common ground for both speakers, which can lead to "crosstalk"—basically, the left signal leaking into the right. The 4.4 mm jack is sturdier, has more surface area for contact, and allows for a "balanced" connection where each side has its own positive and negative lead.

But for most of us, the 3.5 mm is the "good enough" king. It's small enough for a thin phone but large enough that it doesn't snap off like a toothpick (looking at you, 2.5 mm jacks).

🔗 Read more: Why the time on Fitbit is wrong and how to actually fix it

Actionable Tips for Better Audio Connections

If you're struggling with a flaky connection, don't just buy new headphones immediately.

First, take a wooden toothpick or a dedicated tiny interdental brush. Gently—very gently—probe the bottom of your device's port. You would be shocked at how much compressed dust comes out. Don't use a metal needle; you'll short out the pins or scratch the contact plating.

Second, check your plug's "stripes." If you are using a headset with a mic (TRRS) on an old laptop that has two separate ports (one for mic, one for headphones), it will not work correctly. You need a "Y-splitter" that breaks those 3.5 mm jack dimensions into two separate TRS plugs.

Third, look for gold plating. It's not just for show. Gold doesn't oxidize. Silver or nickel-plated jacks develop a thin layer of "tarnish" over years, which increases electrical resistance. A quick wipe with 90% isopropyl alcohol on the plug can often fix "crackling" audio instantly.

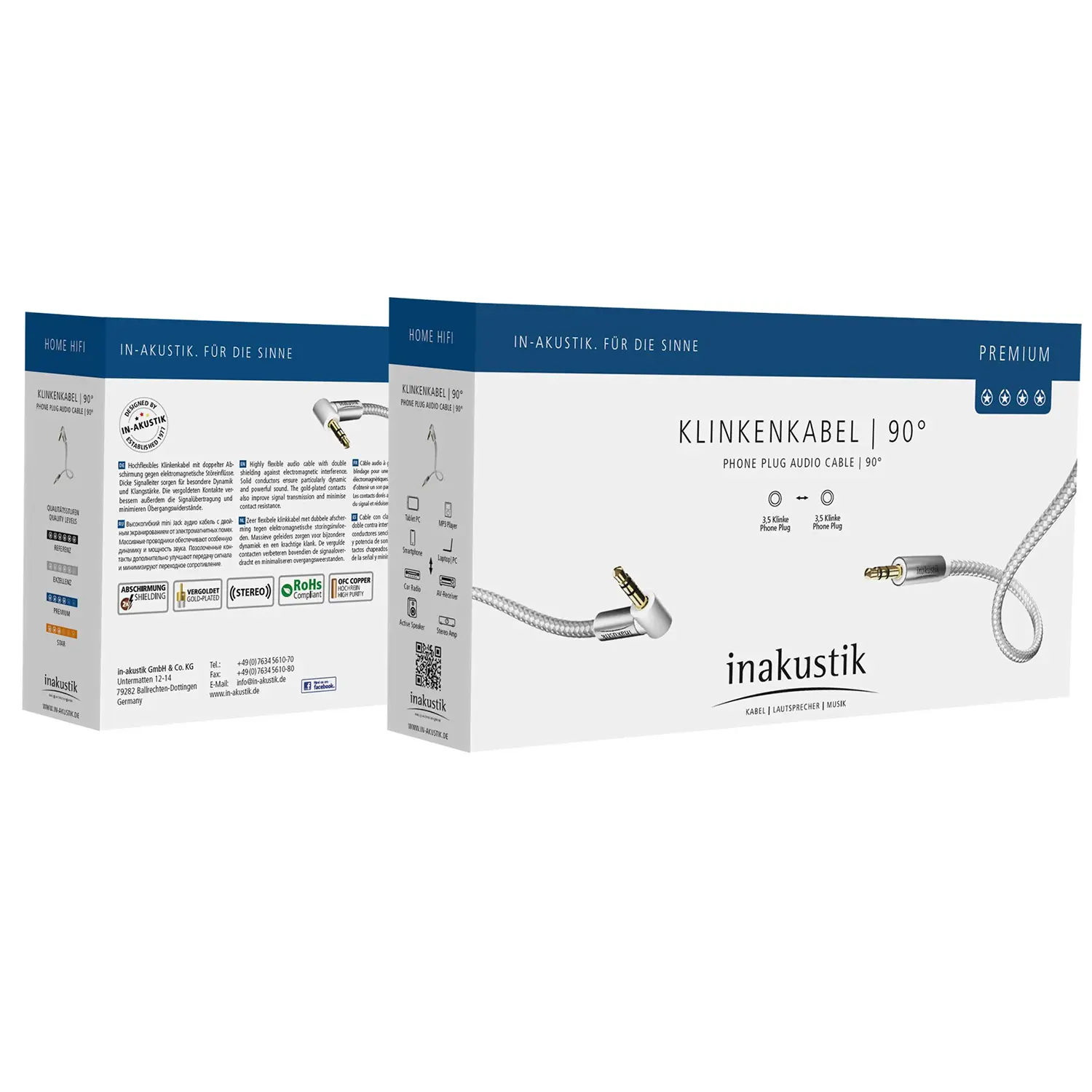

Finally, if you're building or soldering your own cables, pay attention to the "housing" clearance. Use a slim-profile connector if you plan on using it with mobile devices. Brands like Rean or Mogami offer "mobile-friendly" versions specifically because standard studio-grade jacks are too fat for modern consumer electronics.

The 3.5 mm jack is an ancient piece of tech, but its quirks are entirely physical. Understand the measurements, keep the port clean, and it'll probably outlast the device it's built into.

Next Steps for Better Audio:

Check your headphone plug for a "stepped" design if you use a thick phone case. If the metal base doesn't have a small extension before the plastic starts, you're likely putting stress on the internal port. Switching to a slim-profile adapter can prevent your device's internal soldering from cracking over time.