When you hear the number 300 tons, your brain probably glitches for a second. It is just too big to visualize. If you are trying to convert 300 tons to pounds, the math is technically the easy part. You multiply 300 by 2,000 and you get 600,000 pounds. Simple, right? Well, sort of.

The real world is messier than a calculator.

Honestly, the moment you step outside of a classroom, the word "ton" starts to get slippery. Are we talking about the American short ton? The British long ton? Or the metric tonne that the rest of the planet uses? If you are a logistics manager or a construction foreman, getting this wrong by even a tiny fraction isn't just a "whoops" moment. It’s a "the crane just snapped and now we’re on the local news" moment.

The Math Everyone Searches For

Let’s get the basic arithmetic out of the way before we dive into why this number is a beast in the shipping industry. In the United States, we use the short ton.

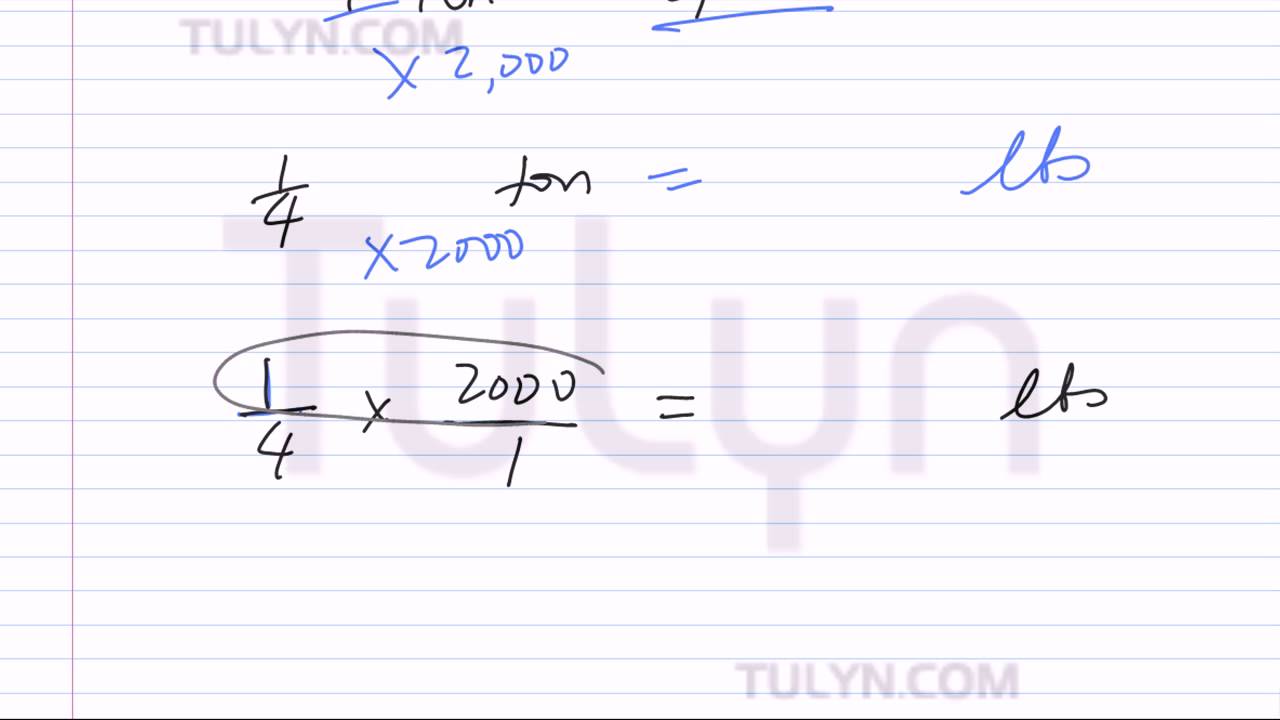

One short ton is exactly 2,000 pounds.

So, for our specific conversion:

$$300 \text{ tons} \times 2,000 \text{ lbs/ton} = 600,000 \text{ pounds}$$

That is a staggering amount of weight. To put it in perspective, a fully grown blue whale—the largest animal to ever exist on Earth—usually tops out around 200 tons. You are looking at one and a half blue whales. Or, if you’re more of a gearhead, imagine about 150 Ford F-150s stacked on top of each other. That’s the kind of mass we are dealing with here.

Why the "Tonne" Changes Everything

Here is where people usually trip up. If you are reading a shipping manifest from a company in Germany or China, they aren't using the 2,000-pound ton. They are using the metric tonne (often spelled with that extra 'ne').

A metric tonne is 1,000 kilograms. When you convert that to the imperial system we use in the States, it comes out to about 2,204.62 pounds.

Now, look at the discrepancy.

If you have 300 metric tonnes, you actually have 661,386 pounds.

That is a difference of over 61,000 pounds compared to the American short ton. That’s an entire extra semi-truck’s worth of weight that you didn't account for. If you’re quoting a price for freight based on 300 tons but you actually have 300 tonnes, you are going to lose a massive amount of money on fuel and tariffs. Or worse, you’ll exceed the gross vehicle weight rating (GVWR) of your equipment.

300 Tons in the Real World: Heavy Lift Logistics

You don't just "move" 600,000 pounds. You engineer its movement.

I remember reading about the transport of massive industrial transformers. These things are the heart of the power grid. A large power transformer can easily hit that 300-ton mark. You can't just throw that on a standard flatbed. You need what’s called a Schnabel car if it’s going by rail, or a multi-axle hydraulic platform trailer if it’s hitting the road.

These trailers sometimes have 20 or 30 axles. Why? Because of pounds per square inch (PSI).

If you put 600,000 pounds on four wheels, those wheels would slice through the asphalt like a hot knife through butter. You have to spread that weight out so the road can actually support it. Engineers have to perform "route surveys" months in advance. They check every bridge. They check the height of every power line. They literally calculate if the turn radius of a specific intersection in rural Kentucky can handle a trailer that is half a block long.

The Hidden Costs of Massive Loads

When you scale up to 300 tons, the costs don't just grow linearly—they explode.

- Permitting: You aren't just paying for a "heavy load" sticker. You’re paying for police escorts, utility bucket trucks to move wires, and sometimes even temporary bridge reinforcements.

- Fuel Surcharges: Moving 600,000 pounds requires an insane amount of torque. The fuel burn is measured in gallons per mile, not miles per gallon.

- Insurance: Most standard business policies won't touch a single-item move of this magnitude. You’re looking at specialized marine or inland cargo insurance that covers "catastrophic loss."

What Most People Get Wrong About Weight

We tend to think weight is static. It isn't.

If you are hauling 300 tons of aggregate (like crushed stone or sand) for a construction project, moisture is your enemy. A heavy rainstorm can add 10% to the weight of an open-air pile of material. Now your 600,000 pounds is suddenly 660,000 pounds.

If you didn't leave a buffer in your weight calculations, your loaders are going to overfill the trucks. This leads to fines at the weigh station. It leads to blown tires. It leads to engine strain.

In the world of high-stakes logistics, you always calculate for the "wet weight" or the "gross weight," never just the theoretical dry number you saw on a spreadsheet.

💡 You might also like: ACC Stock Price: Why Value Investors Are Finally Paying Attention

Contextualizing the 600,000-Pound Mark

To really wrap your head around 300 tons to pounds, think about the Boeing 747-8. Its maximum takeoff weight is actually much higher, but its "empty weight" is roughly in the neighborhood of 220 to 250 tons.

Imagine a 747. Now add a few school buses inside it. That is your 300 tons.

In the mining industry, this is a daily reality. The Caterpillar 797F haul truck—one of the biggest machines on the planet—has a payload capacity of about 400 tons. When that thing is fully loaded, it is carrying 800,000 pounds of rock. The tires alone on those trucks cost $40,000 each and stand 13 feet tall.

Practical Action Steps for Handling Large Conversions

If you are actually dealing with a project involving this kind of mass, don't just trust a quick Google search.

First, verify the unit origin. If the document came from Europe, South America, or Asia, it is almost certainly metric tonnes ($1,000 \text{ kg}$). If it’s a domestic US contract, it’s likely short tons ($2,000 \text{ lbs}$).

Second, account for the rigging. People forget that the steel cables, the spreader bars, and the crates used to hold the 300-ton object also weigh something. In heavy lifting, "tare weight" (the weight of the empty container/rigging) can add several thousand pounds to your total.

Third, check your local regulations. Every state has different laws for "superloads." In some states, 300 tons is a "superload" that requires a specific engineering permit from the Department of Transportation (DOT). You might need a structural engineer to sign off on the path you’re taking.

Finally, always use a safety factor. If your crane is rated for exactly 300 tons, you should not be lifting 300 tons. Most experts recommend staying within 75% to 85% of the rated capacity to account for wind, dynamic loading, and potential equipment fatigue.

Converting 300 tons to pounds is just the start. Managing that weight is where the real work begins. Whether you're balancing a manifest or planning a massive infrastructure project, the difference between a "short ton" and a "metric tonne" is a 61,000-pound mistake you don't want to make.

Next Steps for Accuracy:

Check your shipping contracts for the specific term "MT" (Metric Tonnes) versus "ST" (Short Tons). If it just says "Tons," get a written clarification. Once you have the unit confirmed, apply the 2,000 or 2,204.6 multiplier. Always calculate your "Gross Weight" (cargo + packaging + pallet) before booking freight to avoid surprise "overweight" surcharges at the terminal.