You don't just throw a 12 inch PVC pipe into the back of a pickup truck and head home. It's huge. Honestly, the first time you stand next to a stack of Sch 40 12-inch pipe, you realize it’s less like plumbing and more like infrastructure. We aren't talking about the little white tubes under your kitchen sink. This is the heavy-duty gear that keeps municipal water flowing and prevents your neighborhood from turning into a lake during a thunderstorm.

Most people don't think about it until they see a massive trench cut through a main road.

Why 12 inches? Because fluid dynamics are brutal. When you're trying to move thousands of gallons of water per minute, friction is your enemy. A 12-inch diameter offers a massive cross-sectional area that allows for high flow rates without the astronomical pressure spikes that would burst smaller lines. It's the "sweet spot" for many mid-sized city mains and large-scale industrial cooling systems.

The Weight and the Wall: Schedule 40 vs. Schedule 80

Let’s get into the weeds. If you’re looking at 12 inch PVC pipe, you’re probably choosing between Schedule 40 and Schedule 80.

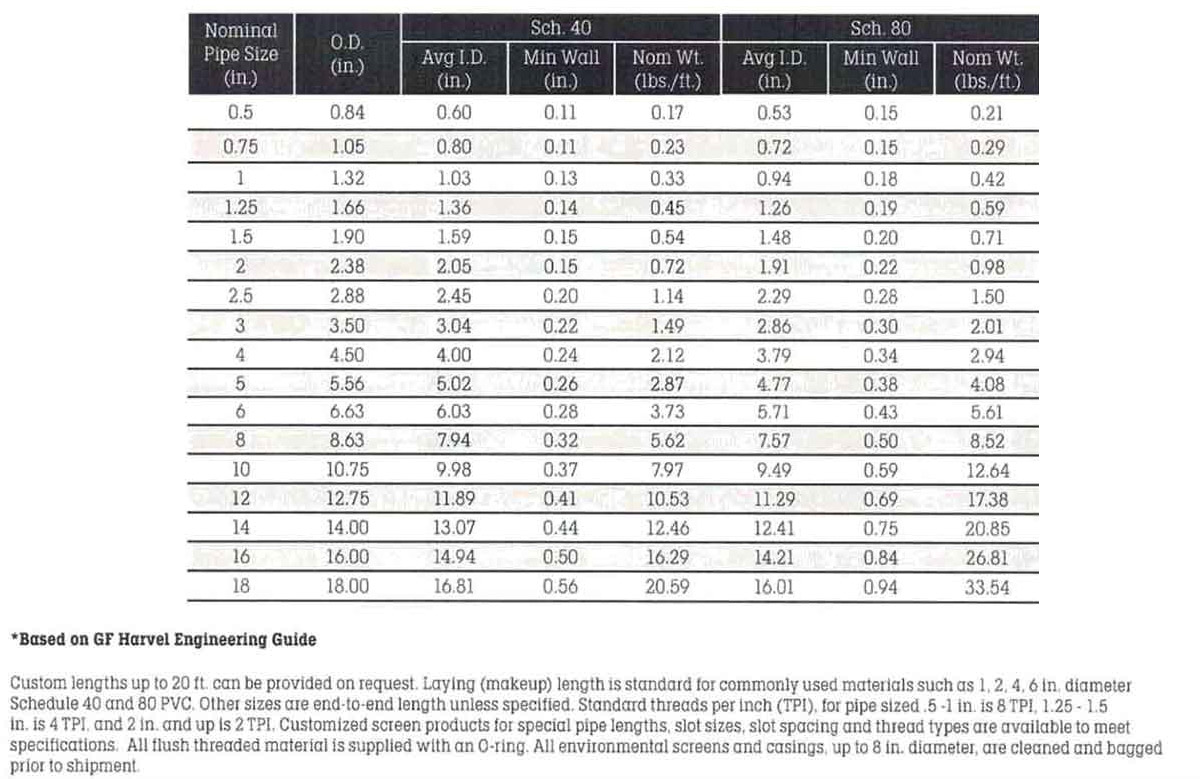

The difference isn't just a number. It’s the wall thickness. A standard 12" Schedule 40 pipe has a wall thickness of about 0.406 inches. That’s nearly half an inch of solid plastic. Move up to Schedule 80, and that wall jumps to 0.687 inches. That’s heavy. It’s sturdy. It’s also significantly more expensive because you’re literally buying more raw resin.

Standard 20-foot sections of this stuff are beasts. A single stick of 12" Sch 40 PVC weighs roughly 190 to 200 pounds. If you’re dealing with Sch 80, you’re looking at over 300 pounds per stick. You need a crew. You need machinery. Attempting to manhandle this solo is a fast track to a back injury and a very expensive mistake.

Pressure Ratings Matter

You can't just swap one for the other. Schedule 40 is usually rated for around 130 PSI (Pounds per Square Inch) at room temperature. Schedule 80 can handle up to 230 PSI. But here’s the kicker that catches people off guard: heat. PVC loses its strength as it gets hot. If you're running fluids at 140°F, that pressure rating drops off a cliff—sometimes by 50% or more.

It's Not All Just Water

We see these pipes in water mains, sure. But the industrial applications are where things get weird. Chemical processing plants love 12 inch PVC pipe because it doesn't rust. Think about it. If you’re moving corrosive brine or diluted acids, ductile iron or steel is going to get eaten alive in a few years. PVC just sits there. It’s chemically inert to a massive range of substances.

I’ve seen it used in:

- Massive saltwater aquarium filtration systems (think SeaWorld-sized).

- Chilled water loops for data centers.

- Gravity-fed sewage lines where 12 inches is the standard for "neighborhood collector" pipes.

- Mining operations for slurry transport.

The versatility is wild. But there is a downside. UV light. If you leave a 12 inch PVC pipe out in the desert sun for three years without protection, it undergoes "UV degradation." The white or gray plastic turns a yellowish-brown and becomes brittle. It won't necessarily fail immediately, but its impact resistance drops to almost zero. One accidental hit from a shovel and crack—you’ve got a disaster.

✨ Don't miss: Why 1 ln n ln n Shows Up Everywhere in Computer Science

The Joint Struggle: How to actually connect these things

You don't just "glue" a 12-inch pipe. Well, you do, but the process is intense.

For the smaller stuff, you've used that little purple primer and the clear cement. For a 12 inch PVC pipe, you need a "Heavy Bodied" cement. It’s thick. It’s designed to fill the larger gaps inherent in big-bore fittings. You also need a team. One guy applies primer to the bell, another to the spigot. You have to be fast. Once that cement hits, the solvent welding process starts immediately.

If you don't bottom out the pipe in the fitting within those first few seconds, it’s stuck. Halfway in. Forever. I’ve seen projects lose thousands of dollars because a crew was too slow and a 12-inch elbow "set" before it was fully seated.

- Use a mechanical pipe puller for the big stuff.

- Be generous with the primer; it's what softens the plastic for the bond.

- Don't skimp on the cure time. In 12-inch lines, you should wait 24 hours before pressure testing.

Gasketed vs. Solvent Weld

In many municipal water jobs, they don't use glue at all. They use "gasketed" or "push-on" pipe. Each 20-foot section has a bell end with a rubber O-ring inside. You lube up the end of the next pipe and shove it in. This allows for a tiny bit of expansion and contraction, which is vital when the ground shifts or the temperature changes. If you had a 500-foot run of glued 12 inch PVC pipe buried in the dirt, the thermal expansion alone could snap a fitting.

Common Myths and Mistakes

People think PVC is indestructible. It's not.

One major mistake is using it for compressed air. Never do this. If a 12-inch PVC line under 100 PSI of air pressure fails, it doesn't just leak. It shatters. It turns into plastic shrapnel. Because air compresses (and water doesn't), the stored energy is massive. OSHA will shut your site down in a heartbeat if they see 12-inch PVC being used for high-pressure shop air.

Another one? Thinking "PVC is PVC."

Actually, there are different cell classes. ASTM D1784 governs the compounds. If you're buying pipe for a specialized industrial application, you need to check the cell class to ensure it has the right impact resistance and tensile strength.

The Cost Reality

Prices for 12 inch PVC pipe fluctuate like crazy. Since PVC is a petroleum-based product, its cost is tied to the oil market and resin availability. During the supply chain crunches of the early 2020s, the price of a single stick of 12-inch pipe tripled in some regions.

Currently, you're looking at anywhere from $30 to $60 per foot depending on the schedule and the volume of the order. Shipping is the hidden killer. You can fit maybe 80 to 100 sticks on a flatbed trailer. If you only need two sticks, the freight cost might actually be higher than the cost of the pipe itself.

Maintenance and Longevity

The "set it and forget it" reputation of PVC is mostly true. Buried in the right soil, away from UV light and protected from "water hammer" (sudden pressure surges), a 12 inch PVC pipe can easily last 50 to 100 years.

✨ Don't miss: Chromebook With a Touch Screen: Why Most People Are Still Buying the Wrong One

Surge pressure is the real assassin. If a pump kicks on or a valve slams shut too fast, a shockwave travels through the line. In a 12-inch pipe, that’s a lot of moving mass. If that shockwave exceeds the pipe's pressure rating, it can split the pipe lengthwise. Engineers usually design these systems with "Variable Frequency Drives" (VFDs) on the pumps to ramp the speed up slowly and avoid that hammer.

Practical Steps for Your Project

If you're actually at the stage where you're ordering or installing 12 inch PVC pipe, here is your checklist:

- Verify the Schedule: Don't let a contractor talk you into Sch 40 if the specs call for Sch 80. The wall thickness matters for the long-term structural integrity of the trench.

- Plan the Unloading: You need a forklift or a backhoe with straps. Do not let the delivery driver just "dump" the pipes off the side of the truck. Impact can cause hairline fractures that won't show up until you pressurize the system.

- Check the Bells: Inspect every single bell end for cracks. Shipping 12-inch pipe is rough, and the ends are the most vulnerable part.

- Temperature Adjustments: If it's 100°F outside, your pipe is going to expand. If you're gluing it in the heat and then burying it in 55°F soil, it's going to shrink and pull at the joints. Account for that "thermal contraction."

- Use the Right Lube: If you're using gasketed pipe, use only the manufacturer-approved lubricant. Using dish soap or grease can degrade the rubber gasket over time, leading to leaks you won't find until the ground gets soft.

This isn't just plastic. It’s the backbone of modern utility work. Treat it with a bit of respect, handle it with the right machinery, and it'll do its job for a century.