Ever tried to hang a heavy mirror and realized the drill bit is just a tiny bit too big? You look at the wall. You look at the screw. You realize that somewhere between 1/16 to 1 inch, things got weird. Most people think measuring is easy until they actually have to build something that doesn't wobble. Honestly, that three-quarter inch difference is where most DIY projects go to die.

It's about scale.

When you're dealing with a range as specific as 1/16 to 1 inch, you aren't just measuring length. You're measuring tolerance. You're measuring the "wiggle room" that keeps a shelf from collapsing or a pipe from leaking all over your new hardwood floors. People treat these small increments like they’re interchangeable. They aren't. A 1/16th of an inch is the thickness of a US penny. An inch is roughly the length of the top joint of your thumb. If you confuse the two in plumbing or fine woodworking, you’re basically asking for a disaster.

The Reality of the 1/16 to 1 inch Scale

Let’s talk about drill bits for a second. If you’ve ever stared at a plastic index case, you know the frustration. You need a 3/16 bit, but you grab the 1/4 because it "looks close enough." It isn't. In the world of fasteners and pilot holes, that 1/16th gap is the difference between a screw that bites into the wood and one that just spins aimlessly in a stripped-out hole.

Small numbers matter.

Machinists live in the world of thousandths, but for the rest of us, the 1/16 to 1 inch range is the standard for accuracy. If you're buying a wrench set, you’ll notice they move in these tiny jumps. Why? Because nuts and bolts are standardized to the point of obsession. You can’t use a 1/2 inch wrench on a 9/16 nut. You’ll just round off the corners and end up swearing at a piece of cold steel in your driveway.

Standardization saved the industrial world. Back in the early 1800s, there was no such thing as a "standard" inch. Every workshop had its own idea of what an inch was. If your carriage broke in a different town, you couldn't just buy a replacement bolt. You had to have one custom-made. It was a nightmare. Then came Joseph Whitworth and later William Sellers, who realized that if everyone agreed on the distance from 1/16 to 1 inch, we could actually build a civilization.

Why Fractional Math Breaks Our Brains

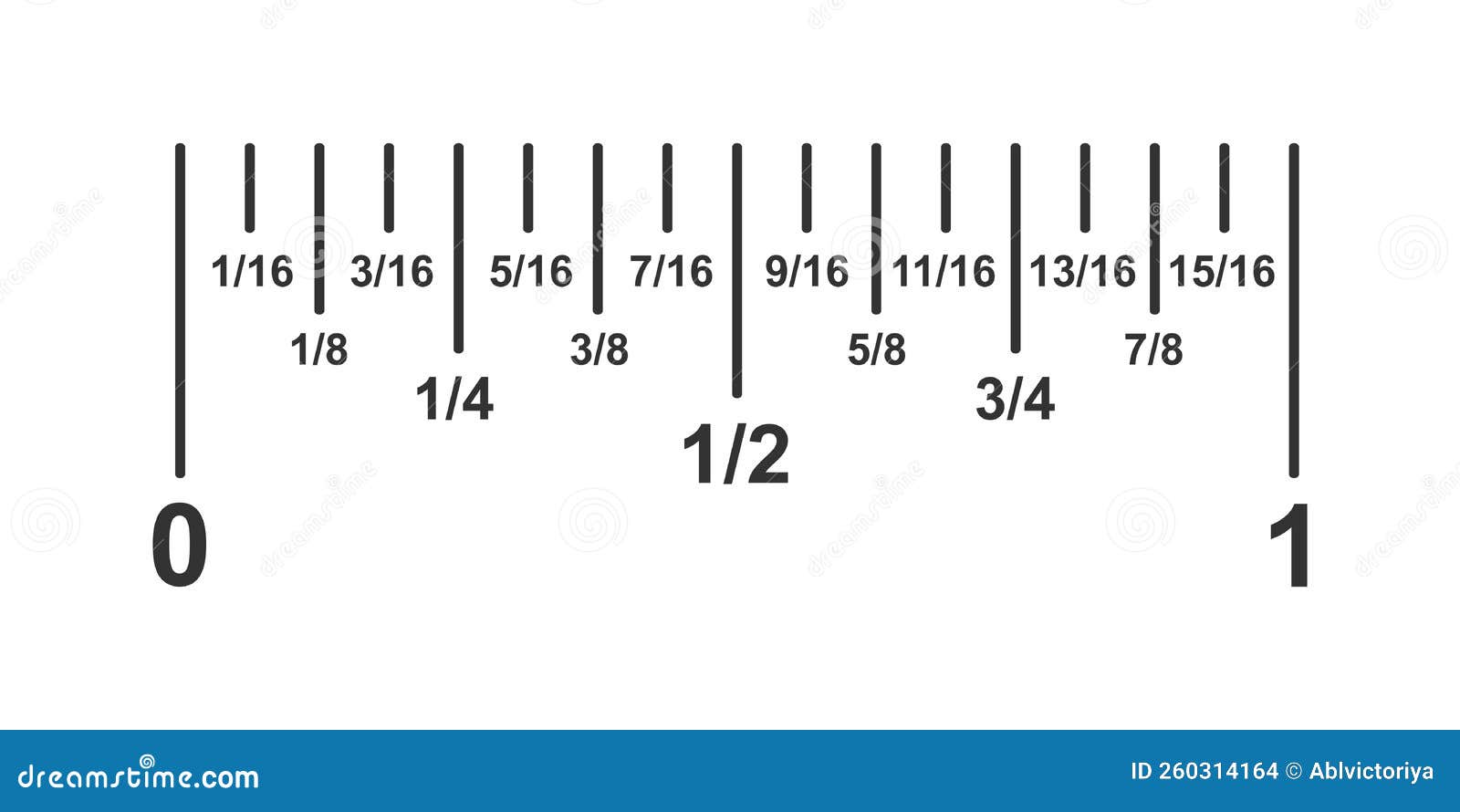

Most of the world uses the metric system for a reason. It’s easier. Ten millimeters make a centimeter. Done. But in the US, we’re stuck with these awkward fractions. 1/16, 1/8, 3/16, 1/4, 5/16, 3/8... it feels like a middle school math test you didn't study for.

💡 You might also like: The Recipe Marble Pound Cake Secrets Professional Bakers Don't Usually Share

Think about it.

When you see 0.5 inches, your brain immediately knows that’s half. But when you see 7/16, you have to do a mental calculation to realize it’s just a hair under half an inch. This mental friction leads to "eyeballing it." And eyeballing it is how you end up with crooked cabinets.

I remember talking to a flooring contractor who told me his biggest pet peeve was "the ghost 16th." This happens when you measure a room and realize it’s not exactly 12 feet wide. It’s 12 feet and 1/16th. If you ignore that across twenty rows of laminate flooring, by the time you reach the other wall, your last plank is going to be slanted. Small errors compound. That's the physics of measurement.

Practical Tools for the Small Stuff

If you're working within the 1/16 to 1 inch range, throw away the cheap plastic ruler you got in a back-to-school sale. Those things are printed by machines that don't care about your accuracy. The lines are often thick and blurry.

What you actually need:

- A stainless steel "machinist's rule." These usually have markings for 32nds and 64ths of an inch.

- Digital calipers. If you really want to know if that bolt is 5/8 or 11/16, a pair of calipers will tell you in seconds.

- A tape measure with a "true zero" hook.

The hook at the end of a tape measure is supposed to wiggle. People think it’s broken and try to rivet it tight. Don’t do that. That wiggle is exactly 1/16th of an inch—the thickness of the hook itself. It moves so that your measurement is accurate whether you are "hooking" the end of a board or "pushing" the tape against a wall.

The Impact of Humidity on Your Measurements

Here is something most people forget: wood moves. If you measure a piece of oak in a humid garage and it's exactly 7/8 of an inch, and then you take it into an air-conditioned house, it’s going to shrink.

📖 Related: Why the Man Black Hair Blue Eyes Combo is So Rare (and the Genetics Behind It)

It might only shrink by 1/32 of an inch.

That doesn't sound like much. But in a tight joinery situation, like a dovetail joint or a mortise and tenon, that 1/32 change makes the joint go from "perfectly snug" to "rattling around." This is why high-end furniture makers let their wood "acclimate" to a room for weeks before they start cutting. They are literally waiting for the 1/16 to 1 inch variables to stabilize.

Socket Sizes and the Great Metric Confusion

You’ve probably been there. You’re under the sink or under a car. You grab a 1/2 inch socket. It’s too small. You grab a 9/16. It’s too big. You realize the manufacturer used 13mm bolts.

The overlap between 1/16 to 1 inch and the metric system is a minefield.

- 1/4 inch is roughly 6.35mm.

- 1/2 inch is 12.7mm.

- 1 inch is exactly 25.4mm.

Using a "close enough" SAE wrench on a metric bolt is the fastest way to ruin a Saturday. The gaps between these sizes are intentionally small to ensure a tight fit, which prevents the tool from slipping. Slipping tools lead to busted knuckles. Busted knuckles lead to hospital visits. All because of a few sixteenths of an inch.

Understanding Material Thickness

When you go to the hardware store to buy "one inch" lumber, you aren't actually getting one inch. This is the biggest lie in the construction industry. A "1x4" board is actually 3/4 of an inch thick.

Wait, what?

👉 See also: Chuck E. Cheese in Boca Raton: Why This Location Still Wins Over Parents

It’s called "nominal" versus "actual" size. The board starts as a full inch when it’s rough-cut at the mill. Then they plane it down to make it smooth, which removes about 1/4 inch of material. If you design a project assuming your wood is a full inch thick, your final product will be smaller than you planned. You have to account for that 1/4 inch loss in every single calculation.

Metal is different. Metal is usually what it says it is. If you buy a 1/16 inch steel sheet, it’s going to be 0.0625 inches thick. This disparity between wood and metal standards causes huge headaches for people building "industrial style" furniture where the two materials meet.

The Art of the "Shoshke"

In some trades, workers use slang for these tiny measurements. A "hair" is usually about 1/64th. A "scosh" or "skosh" (from the Japanese word sukoshi) means just a tiny bit—usually around 1/16th.

Expert craftsmen don't just look at the numbers; they feel them. If you run your fingernail over a seam where two pieces of wood meet, you can feel a "step" as small as 1/100th of an inch. Human touch is incredibly sensitive to these variations. If you're finishing a tabletop, and one board is 1/16th higher than the other, it will look like a mountain range once you apply a glossy finish.

Precision in Household Maintenance

Most people encounter the 1/16 to 1 inch range when dealing with plumbing seals or weatherstripping. If your front door has a 1/8 inch gap at the bottom, you’re losing a massive amount of heat in the winter. It seems like nothing. It’s just a sliver of air.

But air is a fluid.

That 1/8 inch gap across a 36-inch door is the equivalent of having a 4.5 square inch hole in your wall. That’s like leaving a window cracked all year round. Closing that gap with a simple sweep—which usually comes in various thicknesses from 1/4 to 1 inch—can drop your energy bill significantly.

Moving Forward with Accuracy

Stop guessing. If you want your projects to look professional, you have to respect the fractions. Here are the actionable steps to mastering this scale:

- Memorize the "Big Four" Fractions: Know that 1/4 is 0.25, 1/2 is 0.5, 3/4 is 0.75, and 1 inch is 1.0. These are your anchors. Everything else is just a "skosh" above or below them.

- Use a "Story Stick": If you have to make multiple cuts at 7/16 of an inch, don't measure each one with a tape. Mark the measurement once on a scrap piece of wood and use that to set your saw. It eliminates "taper error."

- Check Your Tape Hook: Regularly check the rivets on your tape measure. If they get too loose or too tight, your 1/16 to 1 inch accuracy is gone.

- Buy a Digital Caliper: Honestly, for $20, it’s the best investment you can make for your toolbox. It removes the guesswork from drill bits and bolt sizes instantly.

- Account for "Kerf": Remember that a saw blade has a thickness. Most standard circular saw blades are 1/8 inch thick. If you cut exactly on your line, you just lost 1/8th of an inch of your board to sawdust. Always cut on the "waste side" of your pencil mark.

The difference between a job well done and a frustrated weekend is often just the distance between 1/16 to 1 inch. Measure twice, because you can only cut it once. If you mess up, you can't put the wood back on. High-level precision isn't about being a genius; it's just about having the right tools and the patience to look closely at the little lines.